Multi-sample tobacco moisture adsorption and desorption performance detection device

A technology of adsorption, desorption, and detection device, which is applied in measurement devices, analysis materials, and absorption and weighing of substances, etc., can solve the problems of quality detection deviation, sample temperature cannot be directly detected, and detection efficiency is low, and achieves high detection efficiency. Realize the effect of automatic adjustment and real-time monitoring and protection of load cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is a clear and complete description of the technical solution of the present invention in conjunction with the accompanying drawings,

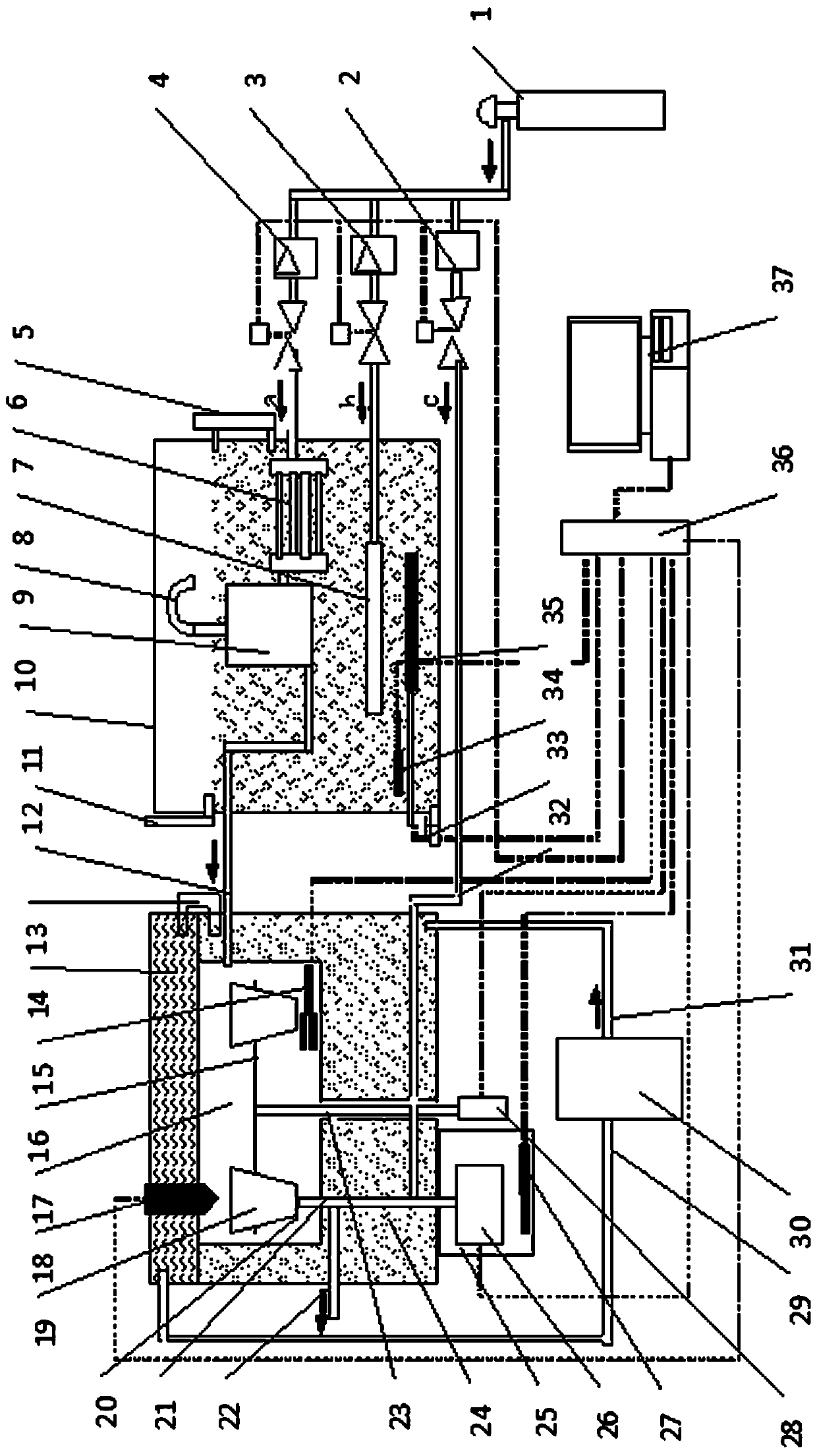

[0037] The structure and connection relationship of the present invention are described below in conjunction with Fig. 1:

[0038] Such as figure 1 Shown: as figure 1 Shown: A multi-sample tobacco moisture adsorption and desorption performance detection device is composed of a treatment atmosphere generation unit, an adsorption and desorption unit, an automatic weighing unit, a data acquisition and a control unit and other parts. And the gas mixing unit and the adsorption-desorption unit are set independently.

[0039] The gas mixing unit mainly includes a high-pressure gas cylinder 1, a gas flow detection control device 4, a gas heat exchanger 6, a b gas flow detection control device 3, a bubble generating device 7, a constant temperature water bath box 10, a heater 35, It is composed of mixing chamber 9, treatment atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com