Metal lamp housing provided with curled edge and edge curling device thereof

A technology of crimping device and lamp housing, which is applied in lighting devices, damage prevention measures of lighting devices, lighting and heating equipment, etc. Aesthetics and other issues, to achieve the effect of novel products, compact device structure, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Such as Figure 6-8 As shown, the embodiment of the present invention provides a metal lamp housing with crimping on the one hand, including the lamp housing main body 16 and the crimping 161 located on the periphery of the lamp housing main body 16, and the crimping 161 is turned outward to form a hook-shaped crimping ;

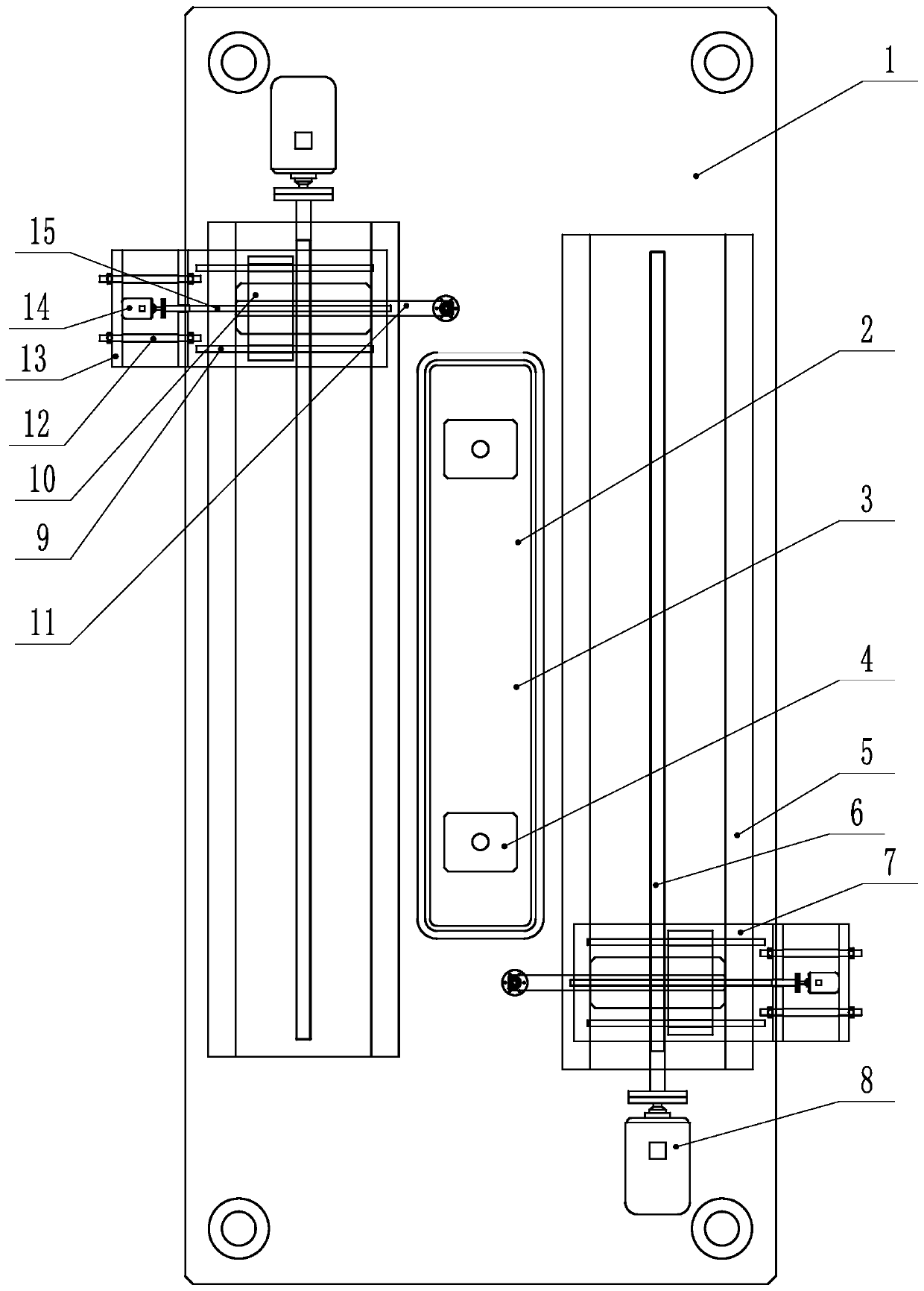

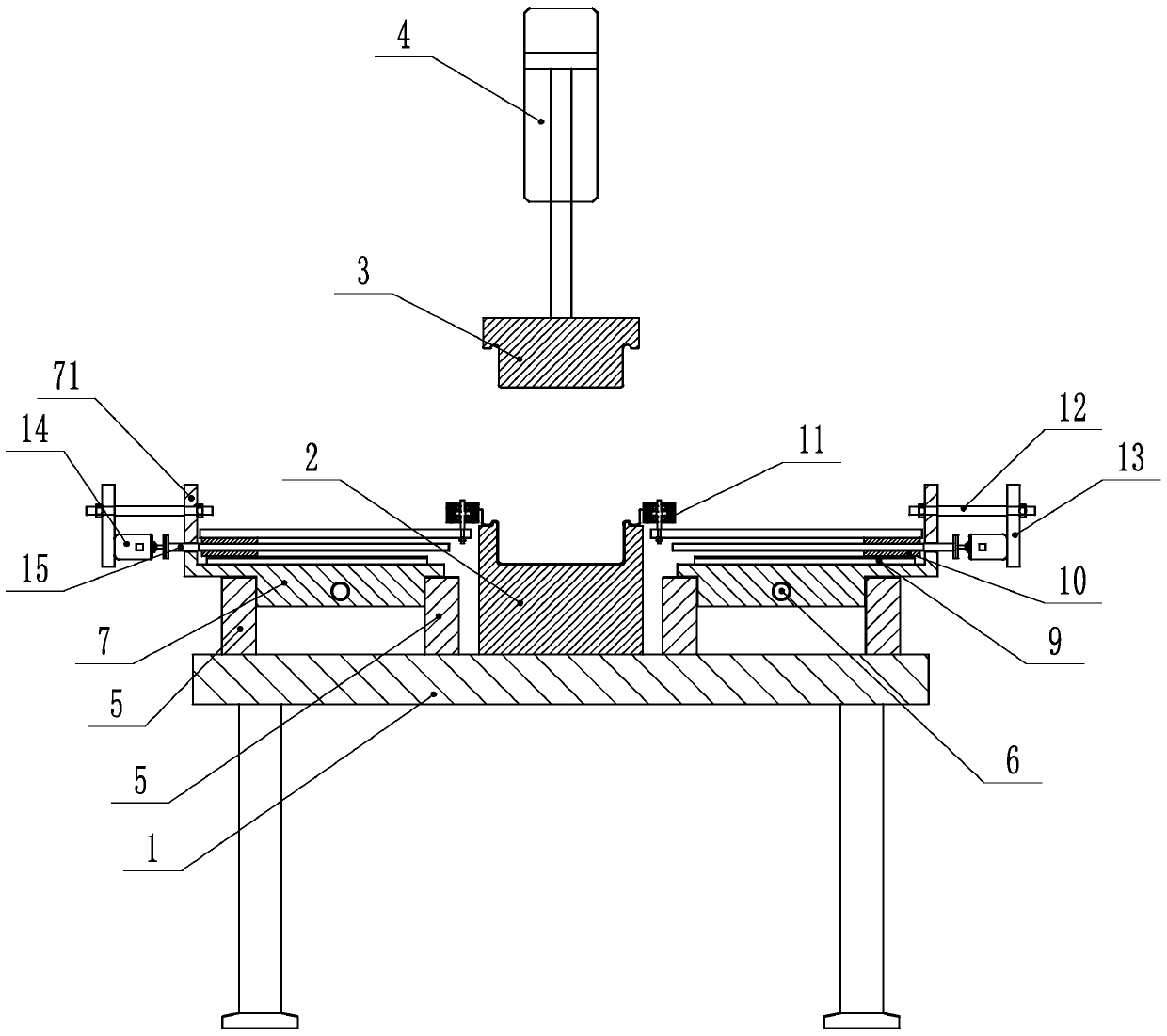

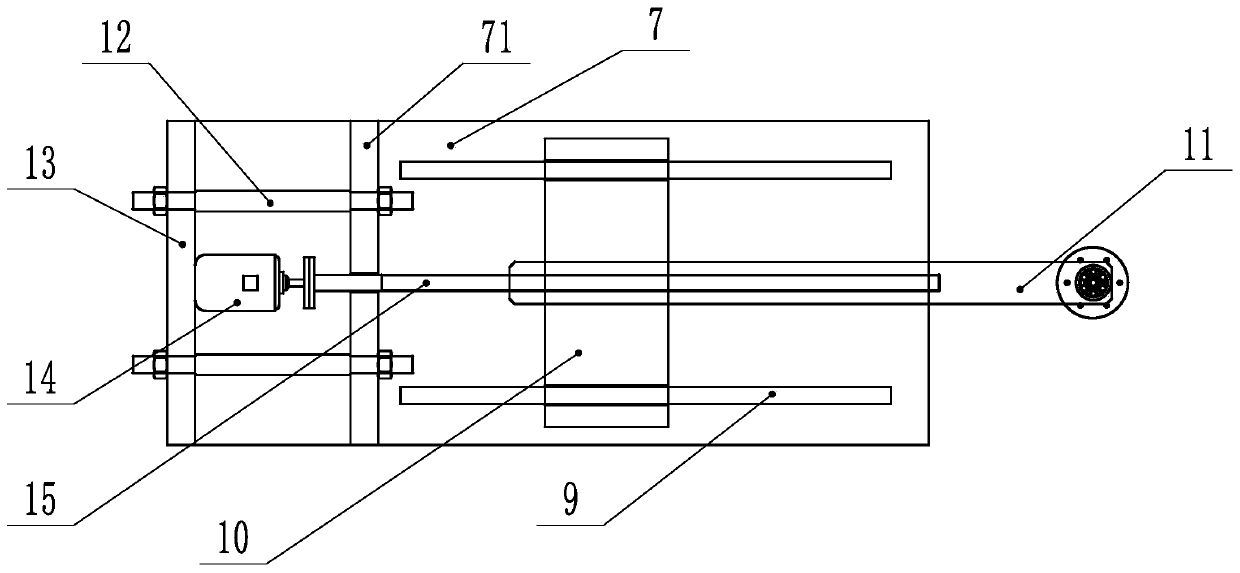

[0026] Such as Figure 1~4 As shown, another aspect of the embodiment of the present invention provides a crimping device for a metal lamp housing with crimping, including a workbench 1, and a middle part of the workbench 1 is fixed along the long side direction for placing the lamp housing main body 16. The lower positioning mold 2 is fixed on the top of the worktable 1, and the cylinder 4 is fixed on the shaft end of the cylinder 4. The upper positioning mold 3 matching the lamp housing main body 16 is fixed, and the workbench 1 is installed on both sides of the lower positioning mold 2 along the length direction. The first slideway 5, the first sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com