Environment-friendly treating system for hot galvanizing wastewater of iron tower

An environmental protection treatment, hot-dip galvanizing technology, applied in metallurgical wastewater treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of resource recovery, treatment system and simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

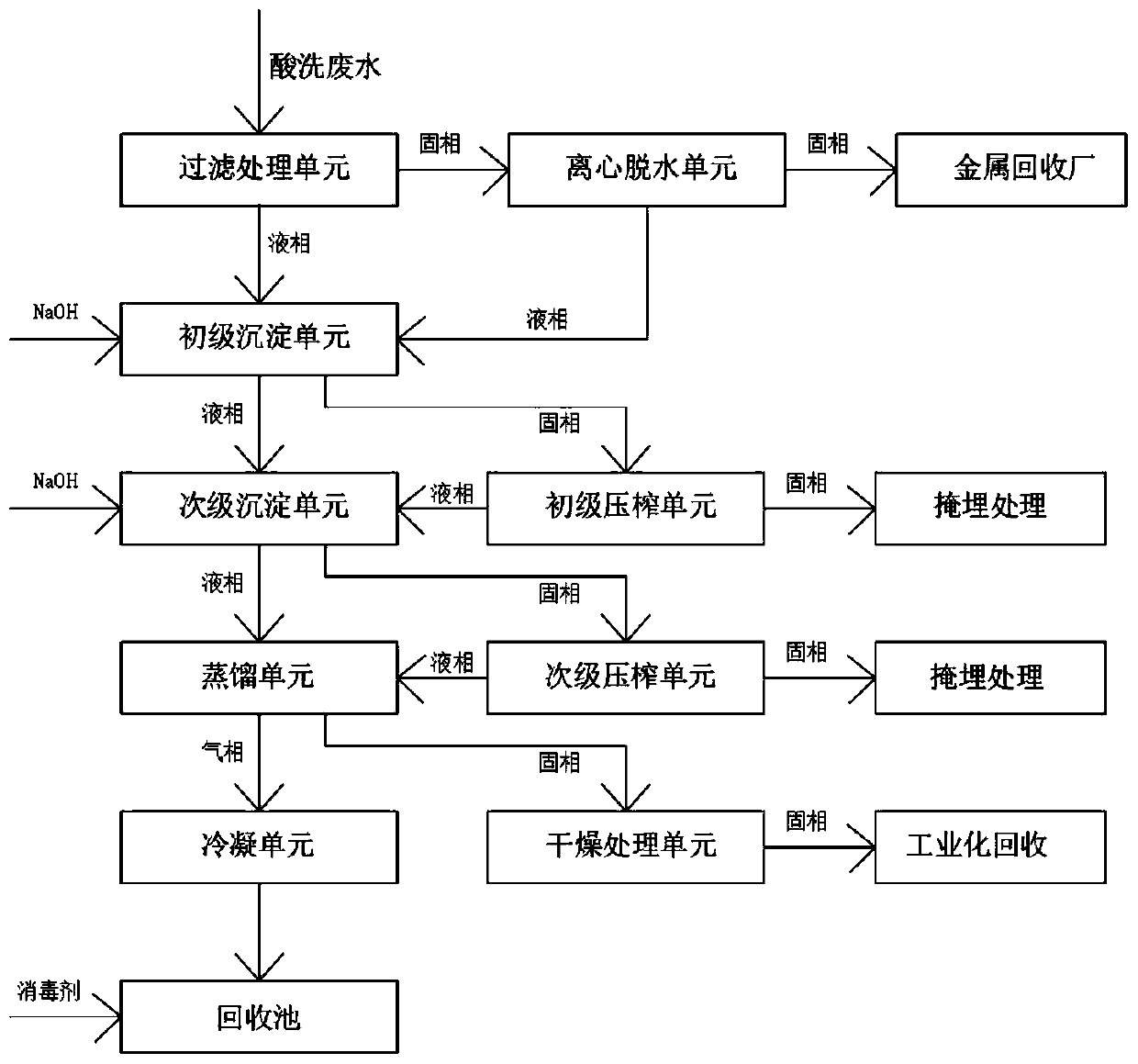

[0025] Such as figure 1 As shown, the embodiment of the present invention provides an environmental protection treatment system for iron tower hot-dip galvanizing wastewater, including a filtration treatment unit, a centrifugal dehydration unit, a primary sedimentation unit, a primary squeezing unit, a secondary sedimentation unit, a secondary squeezing unit, a distillation unit, Dry processing unit and condensation unit.

[0026] Effectively remove iron in wastewater through the cooperation among filtration treatment unit, centrifugal dehydration unit, primary precipitation unit, primary pressing unit, secondary precipitation unit, secondary pressing unit, distillation unit, drying treatment unit and condensation unit At the same time, sodium chloride is recovered, which avoids the problem of pollution caused by direct discharge. The treatment system and process are relatively simple and convenient, and the cost is low. It can carry out large-scale treatment of pickling waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com