Low-temperature propellant in orbit zero-evaporation passive adiabatic storage tank

A low-temperature propellant and zero-evaporation technology, which can be used in aerospace vehicle propulsion system devices, motor vehicles, aerospace vehicle heat protection devices, etc., can solve the problems of inability to support deep space exploration and large propellant evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

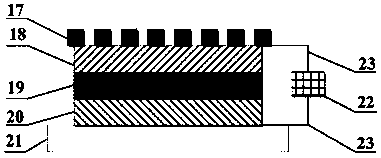

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, a low-temperature propellant space zero-evaporation passive thermally insulated storage tank includes an inner container 1 and an outer container 2, the inner container 1 and the outer container 2 are connected and supported by a support rod 5, and the inner container 1 and the outer container 2 form a The interlayer chamber 3, the outer wall of the outer container 2 is wrapped with a multi-layer heat insulating layer 4;

[0026] The inner container 1 is connected with a first filling pipe 10 and a first discharge pipe 9, and a first regulating valve 11 is installed on the first filling pipe 10, and the first regulating valve 11 controls the on-off of the first filling pipe 10. A first safety valve 8 is installed at the outlet of the discharge pipe 9;

[0027] The interlayer cavity 3 is connected with the second filling pipe 13 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com