Automatic grinding processor for sprue gate of injection molding plastic product

A technology for injection molding plastics and gates, which is applied to the parts of grinding machine tools, machine tools and grinding machines suitable for grinding the edge of workpieces, etc. It can solve the problems of cumbersome operation, lower grinding quality, and the inability to ensure that the surface of disc-type plastic products is on the same plane and other issues to achieve the effect of convenient operation and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

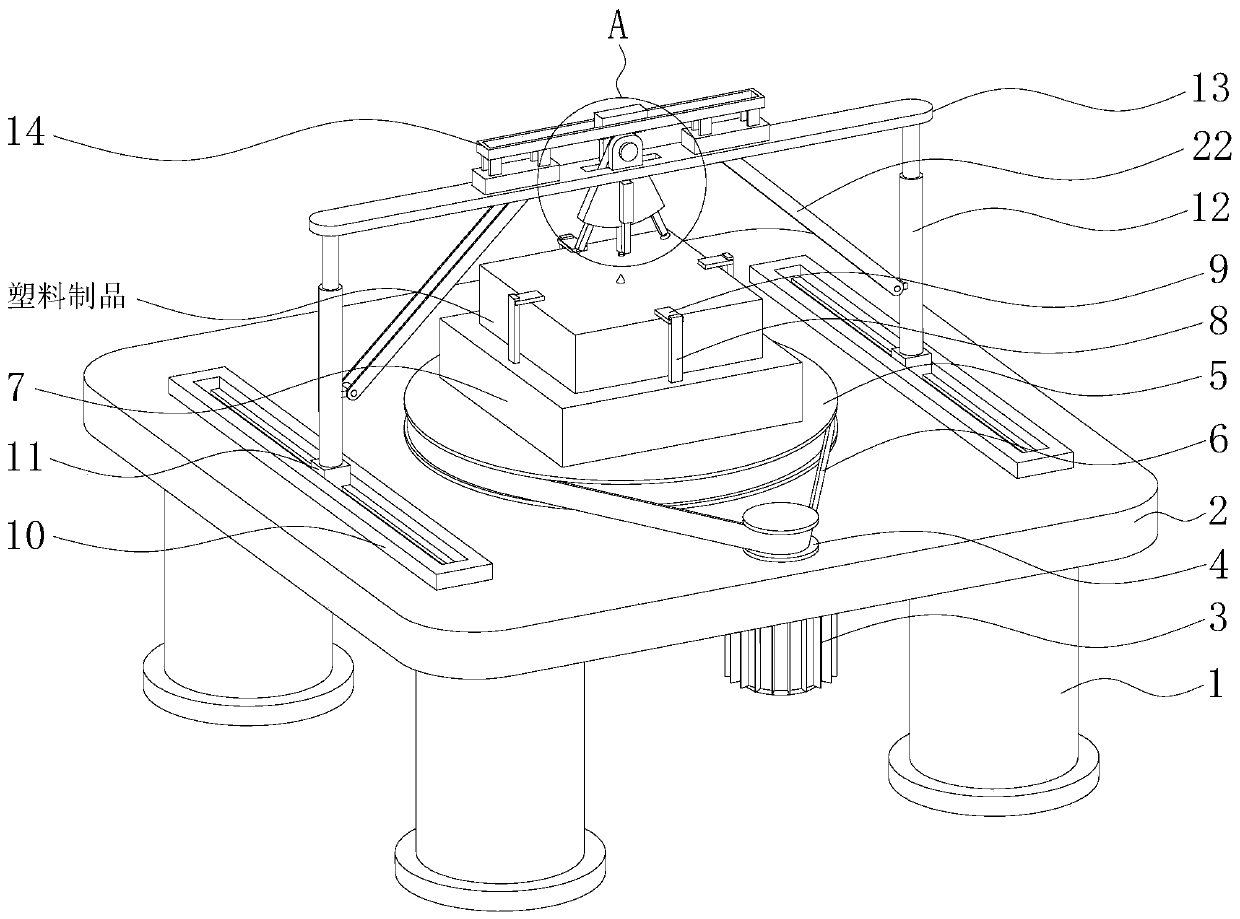

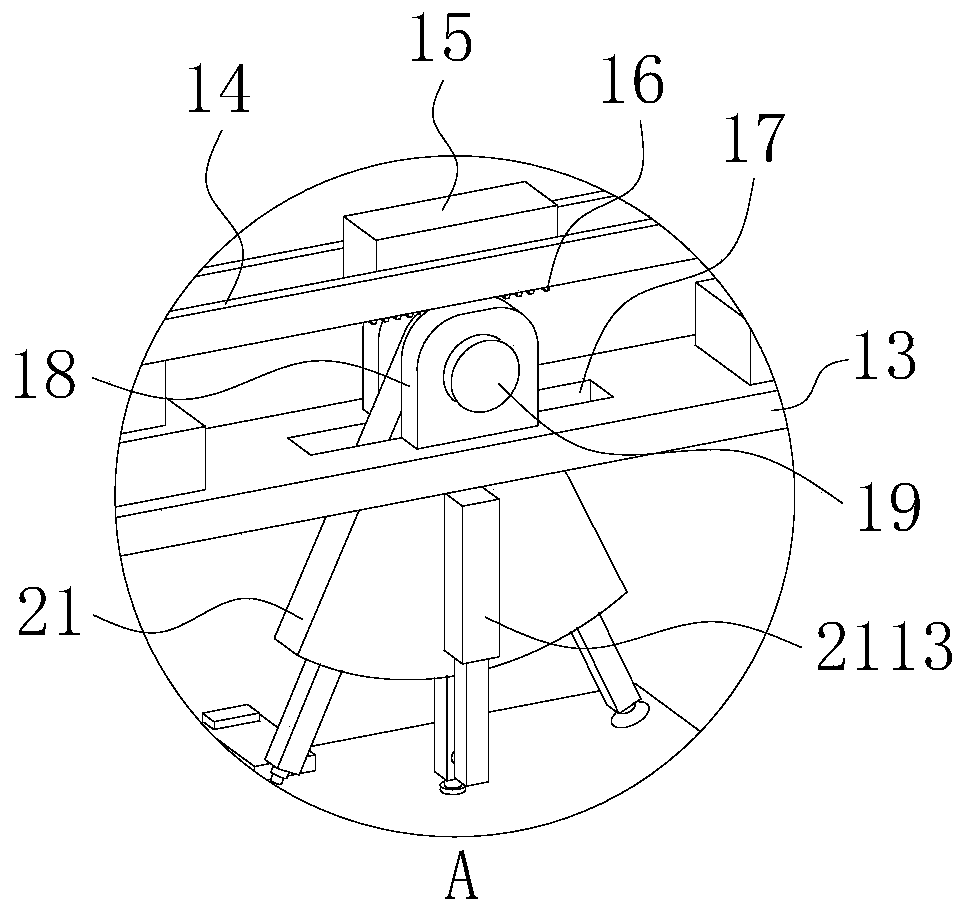

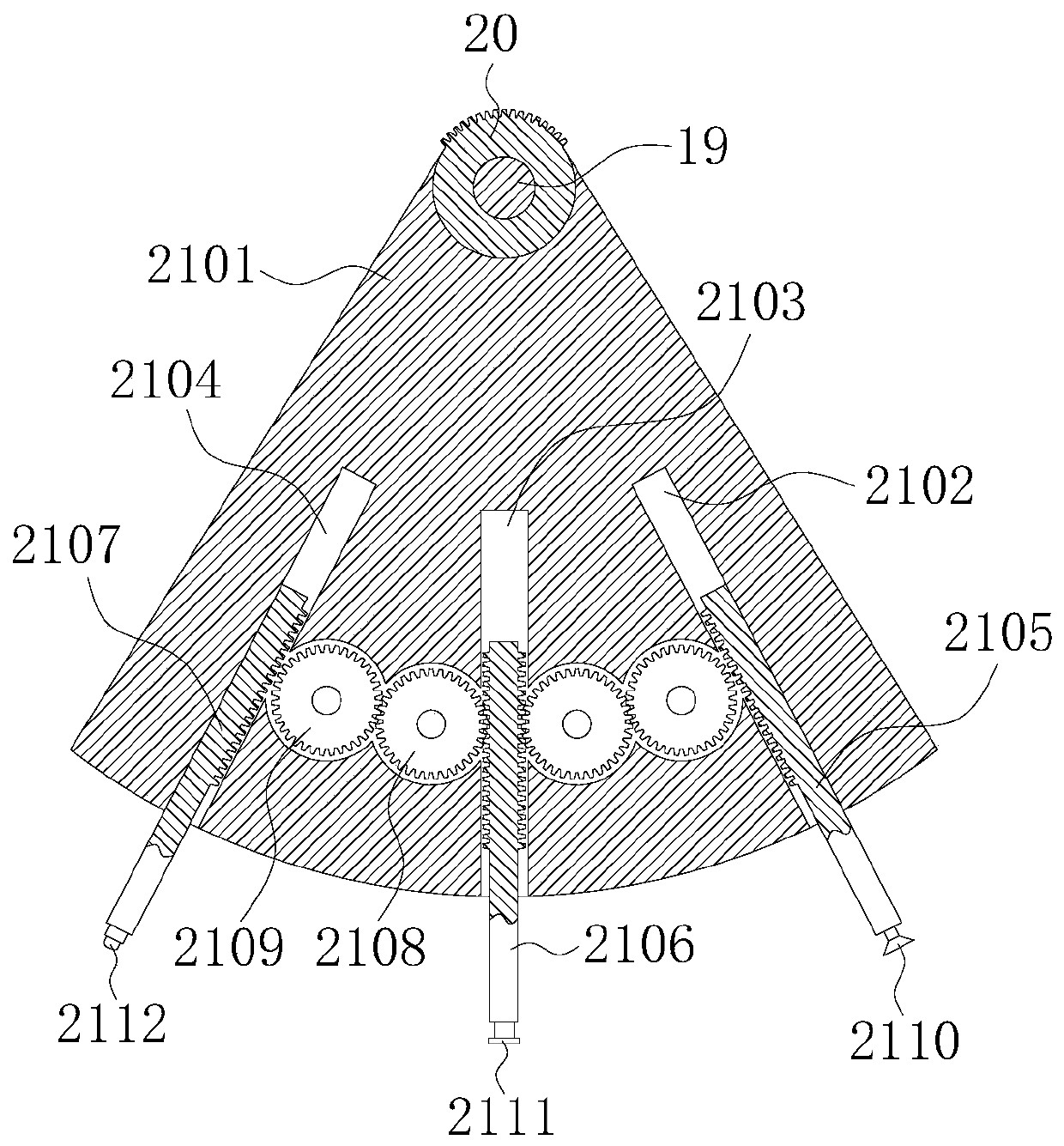

[0028] Such as Figure 1 to Figure 5 As shown, the present embodiment provides an automatic grinding processing machine for pouring gates of injection-molded plastic products, which includes a frame 1 , and a horizontal workbench 2 is fixedly connected to the top of the frame 1 . The lower bottom surface of the workbench 2 is vertically fixed with a rotary motor 3, the output shaft of the rotary motor 3 runs through the workbench 2 and is fixedly connected to the horizontal first pulley 4, and the lower bottom surface of the first pulley 4 is connected to the upper surface of the workbench 2. Surface rotational mate. The upper surface of the workbench 2 is fitted with a horizontal second pulley 5 through the rotation of the fixed rotating shaft. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com