A laser shock wave micro-machining device with rotating beam preheating

A technology of rotating beams and processing devices, which is applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., and can solve the problems of poor quality of micro-modeling processing, surface cracking and splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

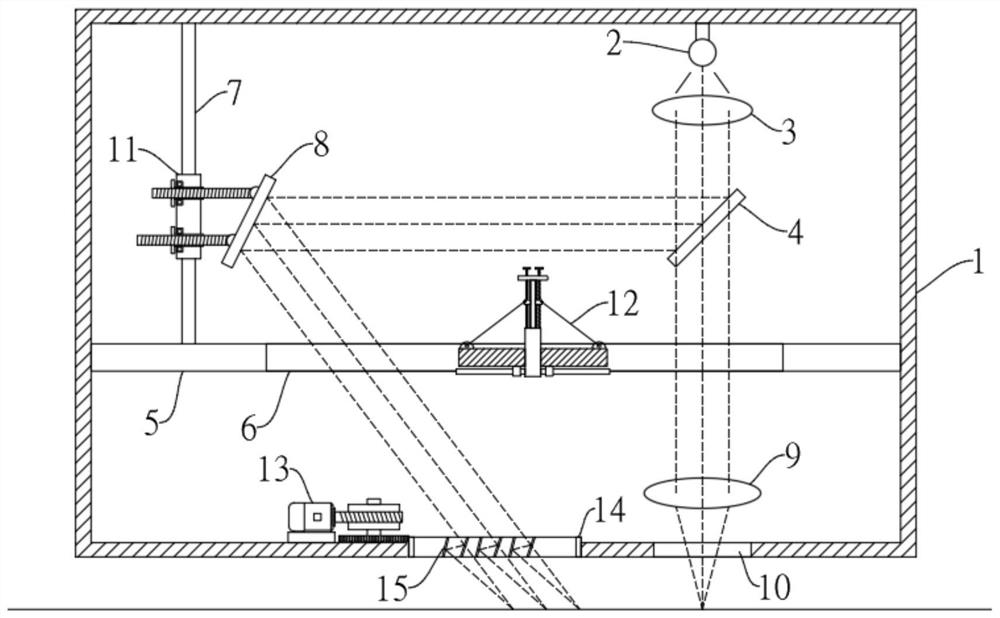

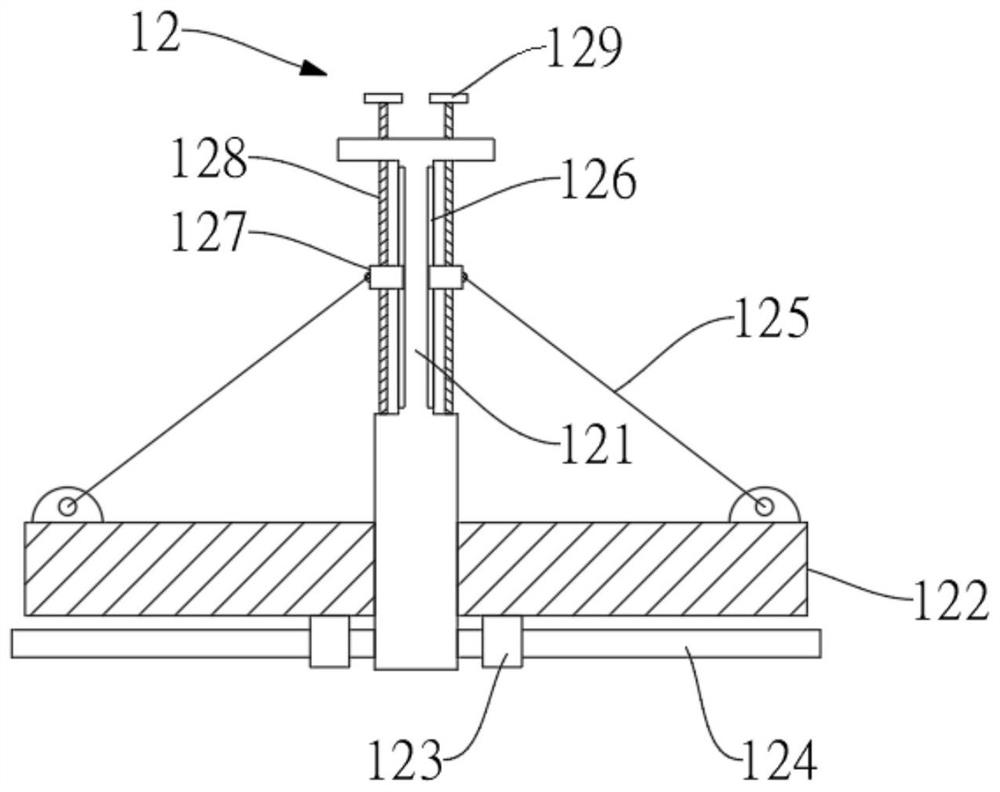

[0028] refer to Figure 1-4 , a laser shock wave micro-molding device for preheating rotating beams, comprising a housing 1, a laser transmitter 2 is arranged on the inner top of the housing 1, a first convex lens 3, a half The reflection mirror 4 and the second convex lens 9 are provided with a light transmission port 10 at a position corresponding to the main optical axis of the laser transmitter 2 at the bottom of the housing 1 .

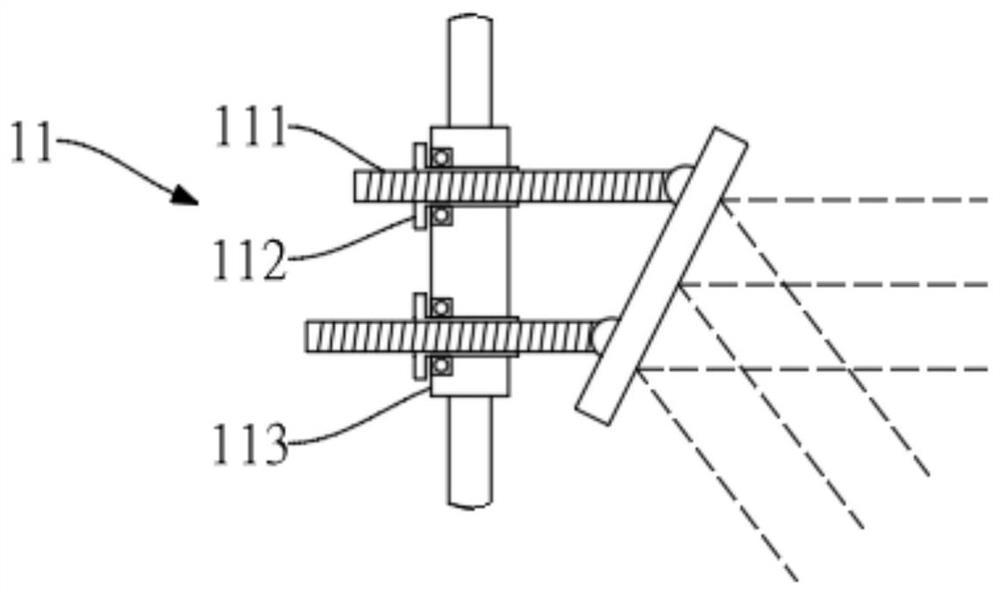

[0029] The reflective main optical axis of the half-reflector 4 is provided with a total reflection mirror 8, and the total reflection mirror 8 is connected with an adjustment ferrule 11 that can adjust its reflection angle, and the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com