Camera imaging error calibration method and correction method

An imaging error and calibration method technology, applied in the field of vision correction, can solve the problems of conflict between calculation accuracy and model accuracy, unstable solution, and camera installation error without considering lens tangential distortion, so as to simplify the calibration process and reduce time. Effects with Complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

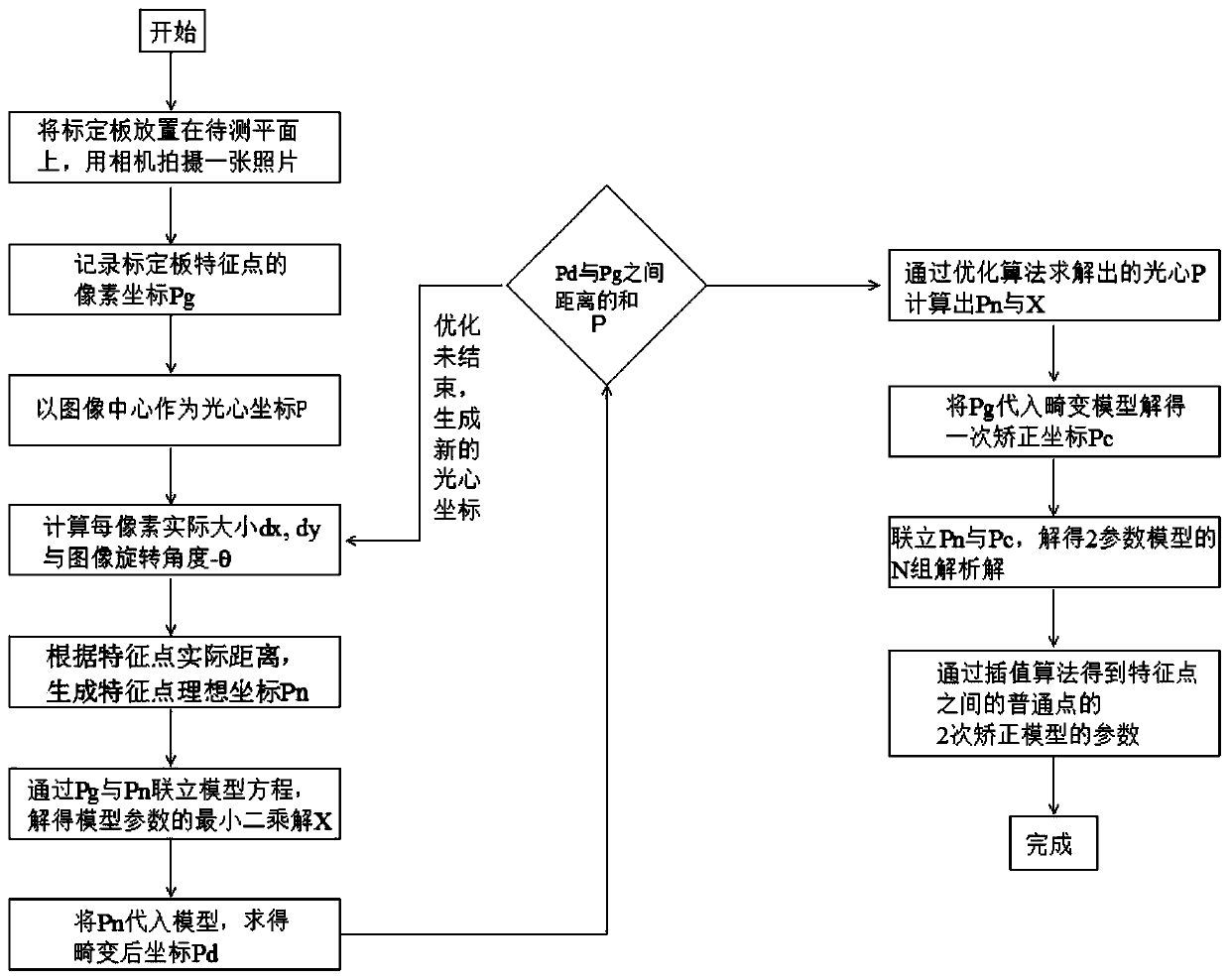

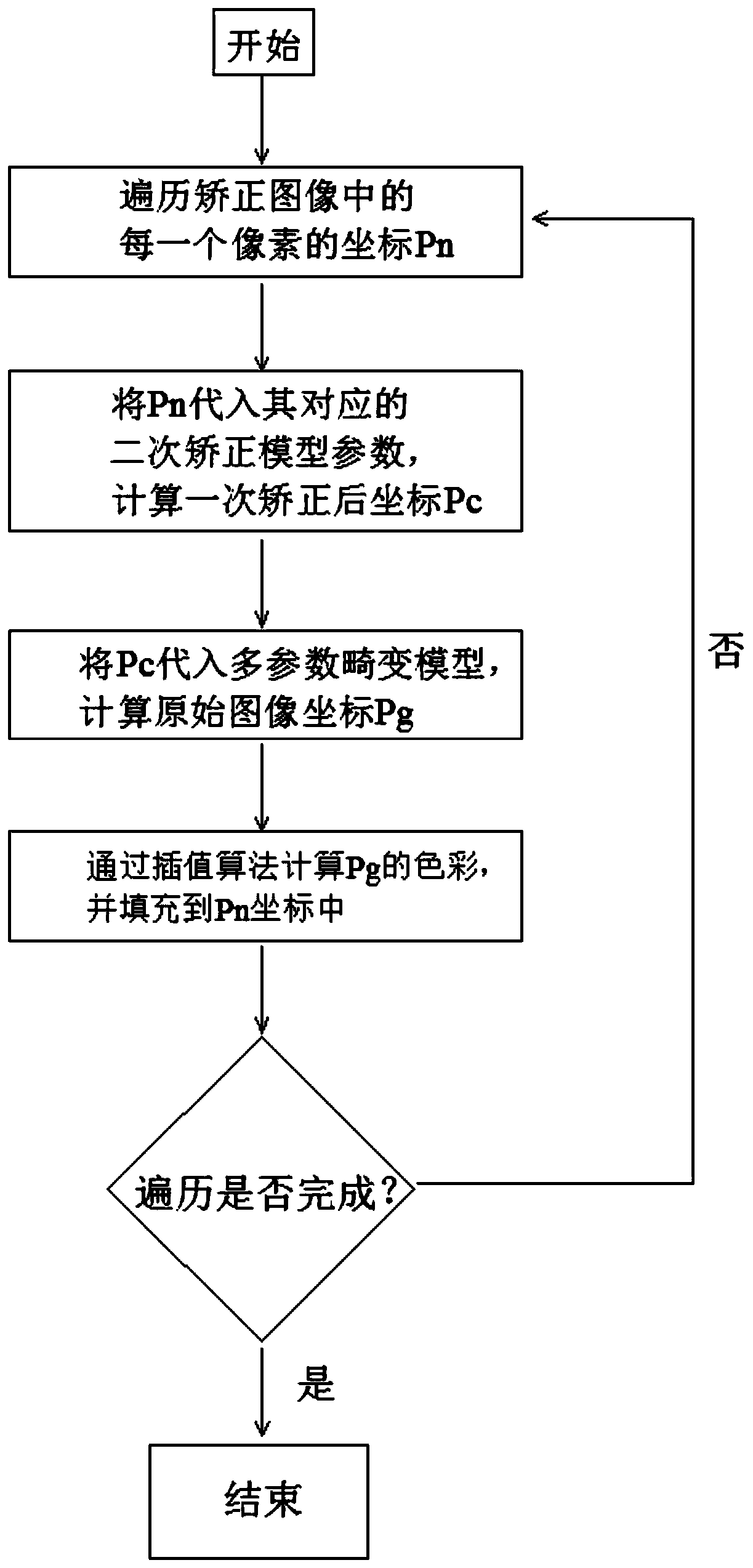

[0050] see figure 1 , the present invention provides a camera imaging error calibration method, comprising the following steps:

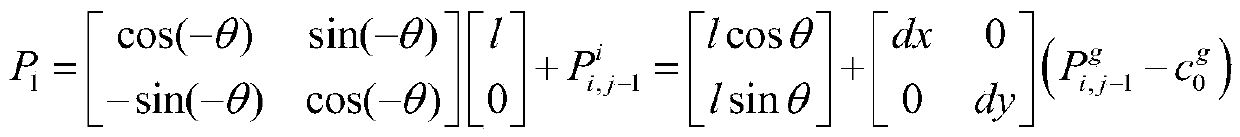

[0051] Step 1: Place the calibration plate on the plane to be tested, shoot the calibration plate with a camera, and send the captured original image to the imaging processing device. Among them, the calibration plate is a precision calibration plate, which is placed on a substrate with high strength and small deformation to write regular patterns, and the precision of the pattern writing determines the upper limit of the accuracy that can be achieved by the method disclosed in the present invention. Generally adopt the traditional calibration method, it is necessary to place the calibration plate in front of the camera to take multiple images from different distances, different positions and different angles, gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com