An online repair method for LNG pipeline cold insulation structure

A repair method and pipeline technology, applied in pipeline protection, pipeline system, pipeline protection through heat insulation, etc., can solve problems such as cracking, enlarged equipment, and damage to the cold insulation layer of LNG pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0060] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

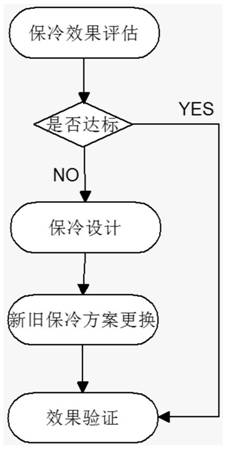

[0061] The flowchart of the online repair method of the present invention is as figure 1 As shown, the method of the present invention is described by taking the cold-preservation structure of the low-temperature pipeline of DN100 as an example with the pipe diameter:

[0062] 1. When evaluating the cold insulation performance of the cold insulation structure of the LNG pipeline, the old cold insulation scheme was designed with reference to the thickness method of the anti-condensation cold insulation layer in GB / T8174-2008 "Test and Evaluation of Thermal Insulation Effects of Equipment and Pipelines", According to the original design parameters of the pipeline actually collected on site, the temperature, flow, pressure and oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com