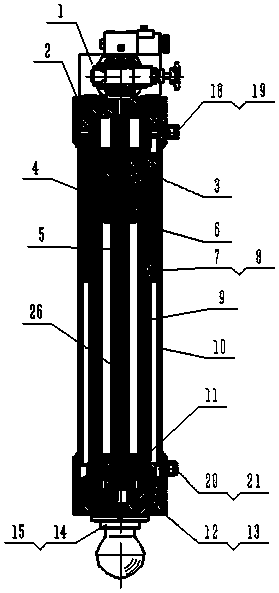

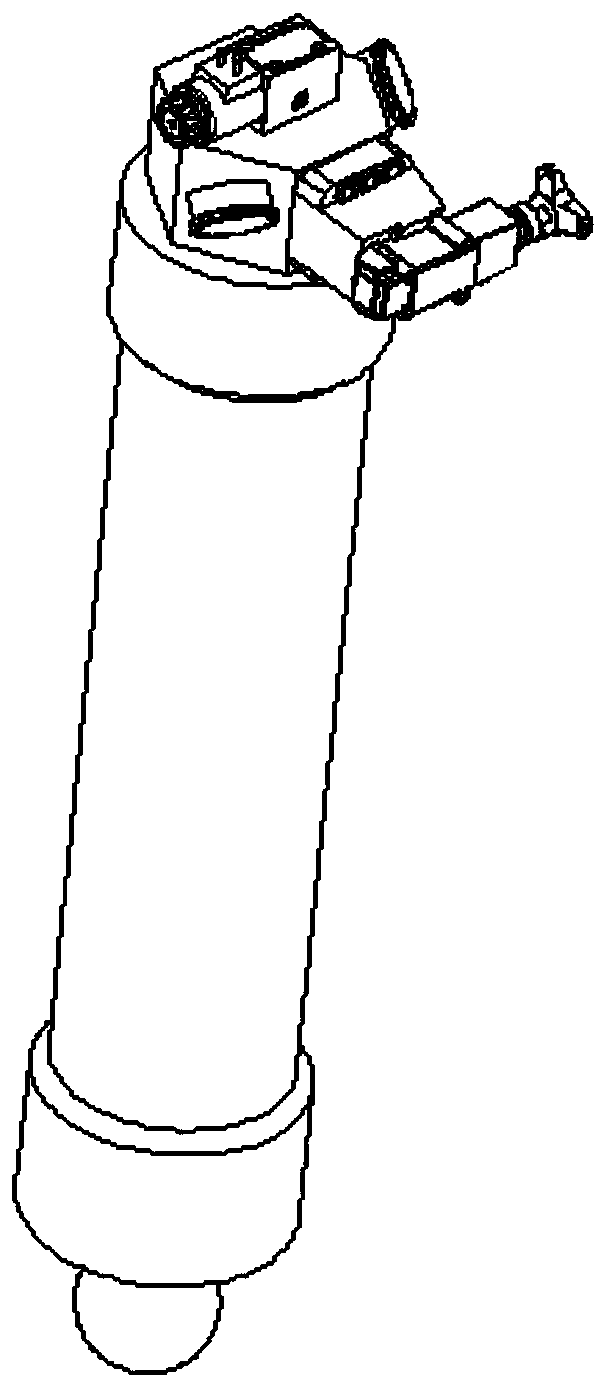

Electro-hydraulic integrated bidirectional locking anti-explosion hydraulic cylinder

A hydraulic cylinder, electro-hydraulic technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve problems such as hidden safety hazards and inability to meet design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

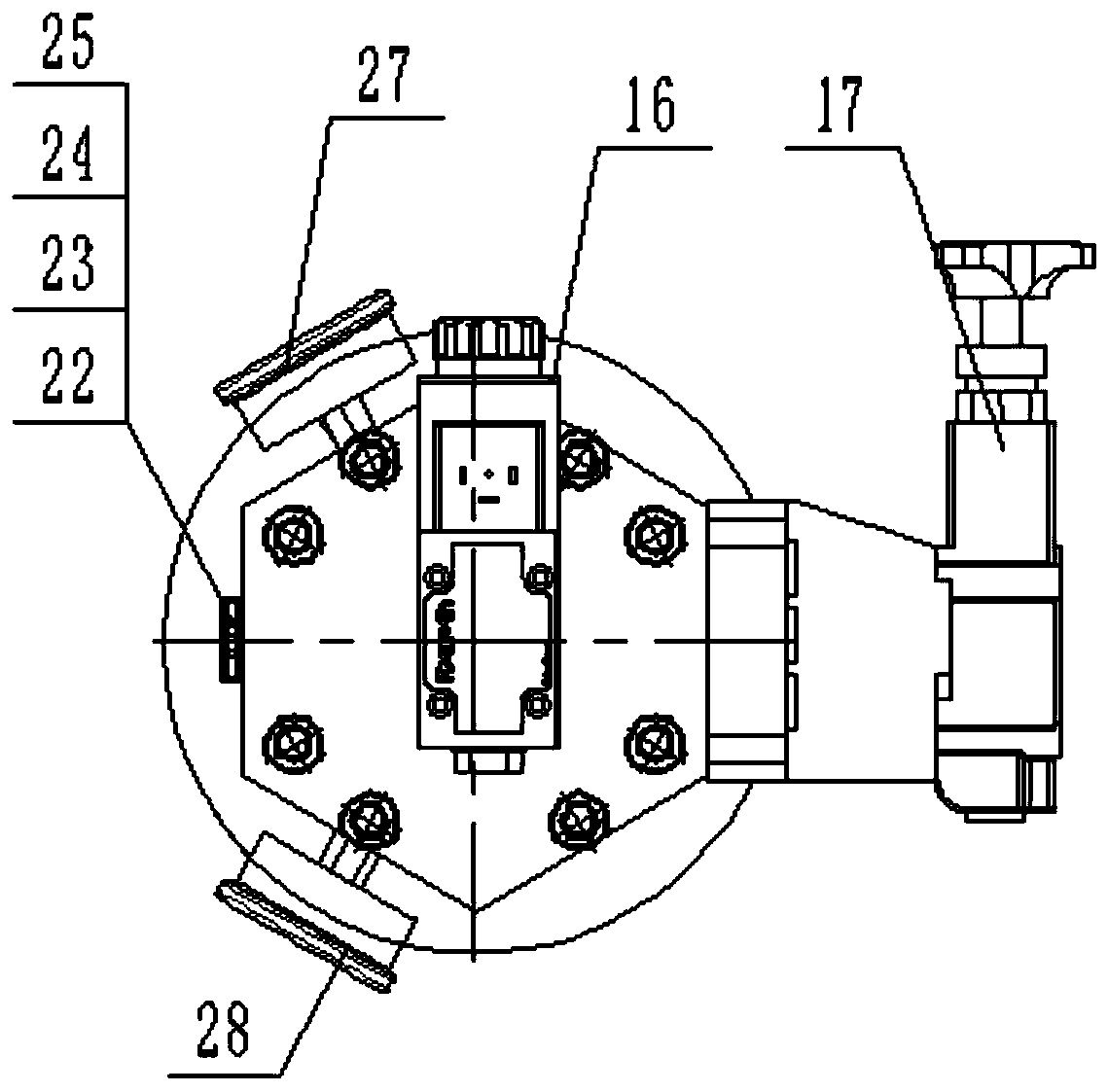

[0009] The electro-hydraulic integrated two-way locking explosion-proof hydraulic cylinder of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. Its characteristics are: the integrated valve block 1 is fixed on the rear end cover 2 with screws, and there are two oil passages on the stop where the integrated valve block 1 is inserted into the rear end cover 2, one of which is welded with the oil pipe 5, and the other is connected to the support column 26, the inner grooves are aligned and lead to the middle oil port of the support column 26, and the support column 26 is welded together with the integrated valve block 1; The other end of the support column 26 is equipped with a rod end limiter 12, the rod end limiter 12 and the support column 26 are screwed together, the oil passage ring 4 is between the guide fixed sleeve 3 and the moving piston 11, and the integrated valve block 1 The oil pipe 5 welded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com