Magazine

a magazine and magazine body technology, applied in the field of magazines, can solve the problems of insufficient elastic force to firmly abut against the air cartridge, the inability to carry external devices, and the inability to carry a gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

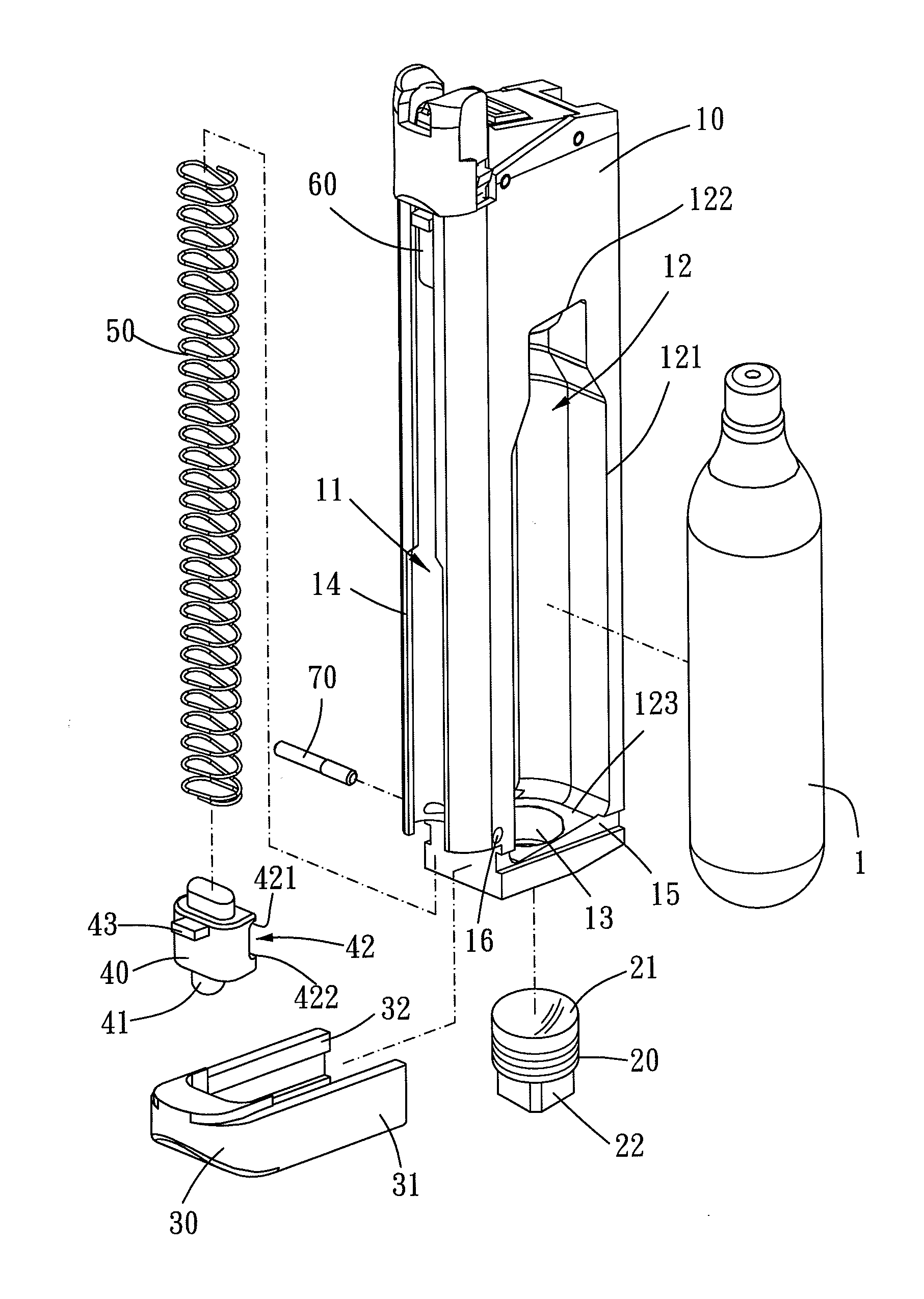

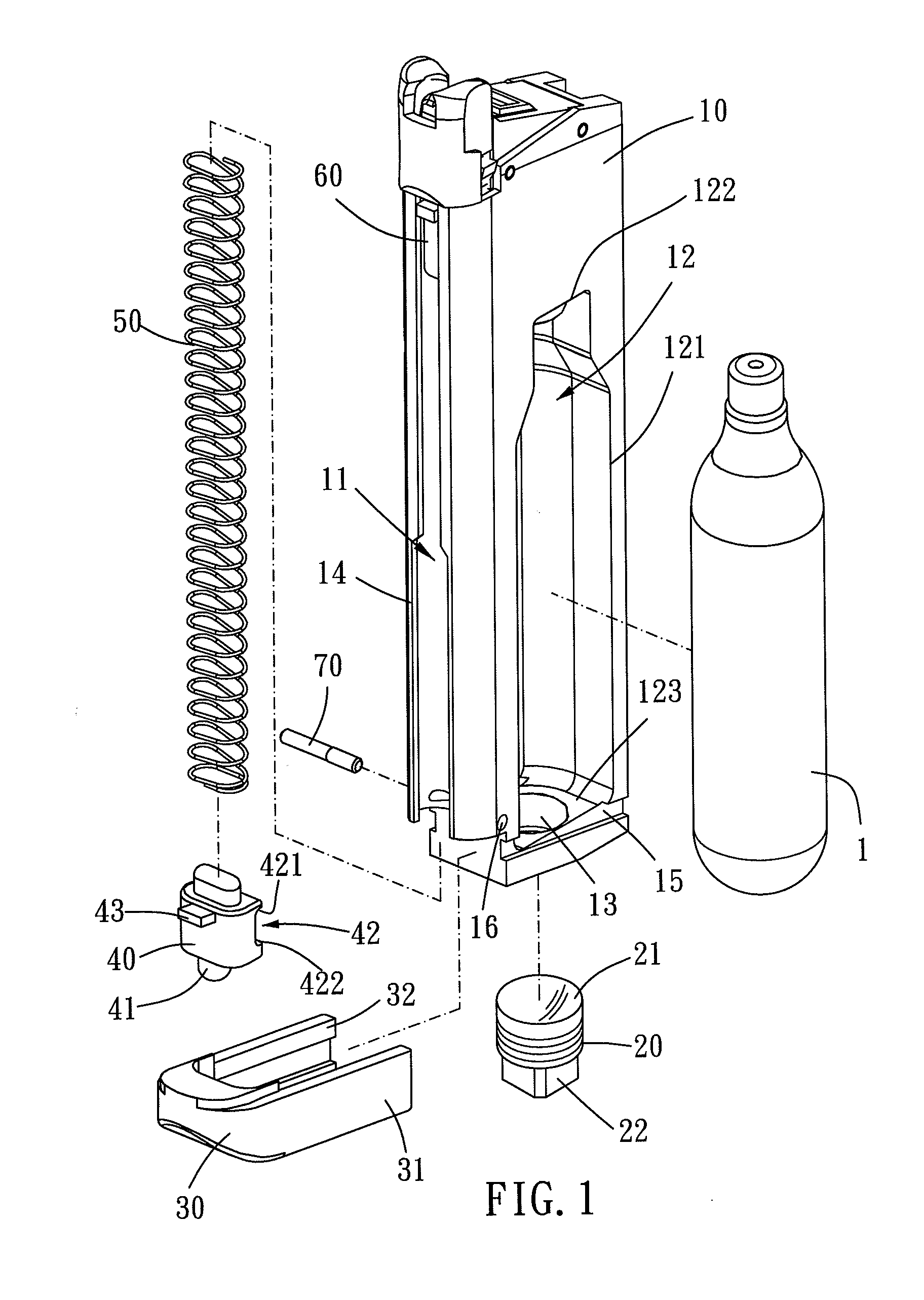

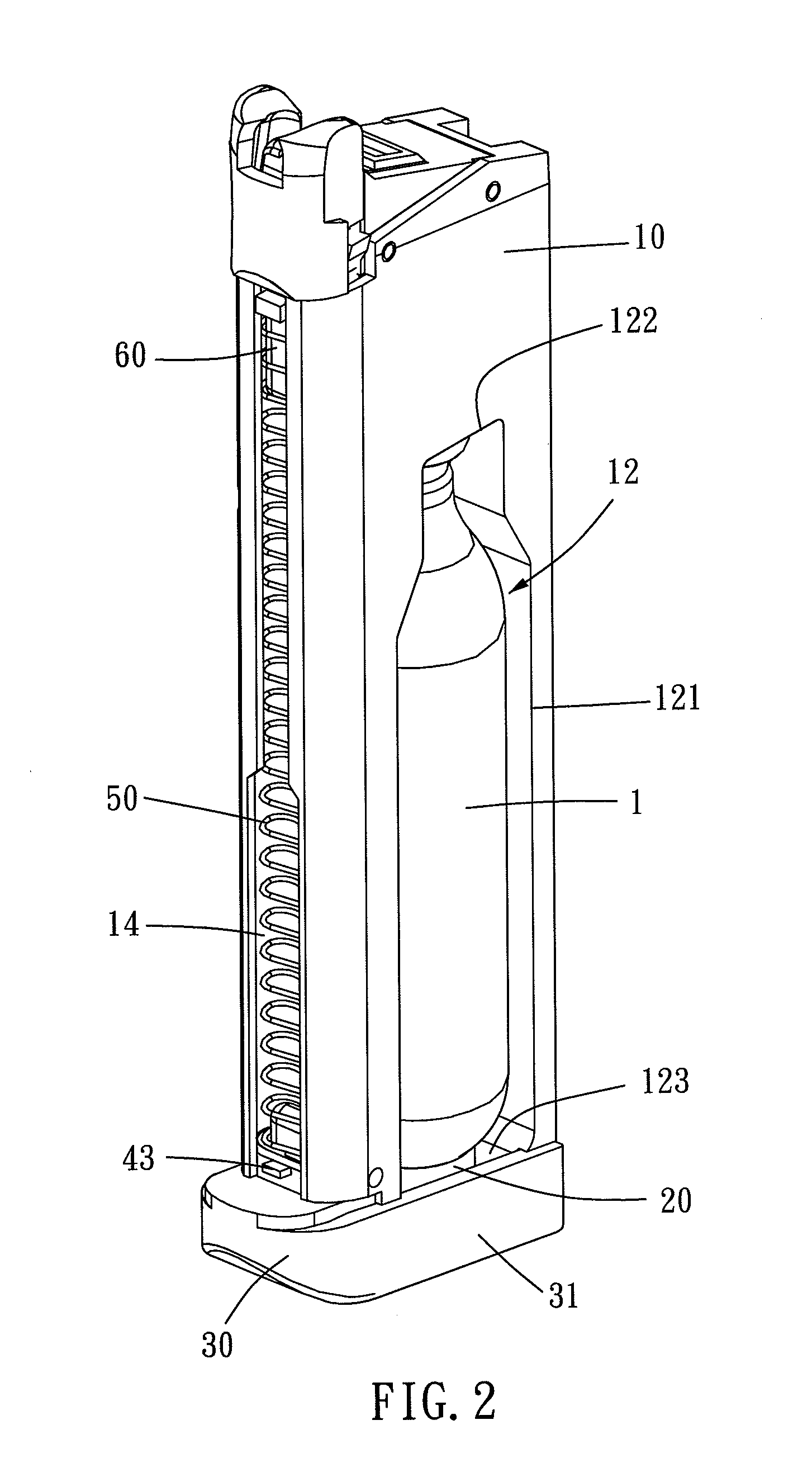

[0016]Please refer to FIG. 1 to FIG. 3 for a preferred embodiment of the present invention. A magazine of the present invention includes a main body (10), a plug member (20), a base (30), an anti-slide member (40), an elastic member (50), a support member (60), and a rod (70).

[0017]The main body (10) is formed with a trough (11), a recess (12), a hole (13), a groove (14) and a limit hole (16). The trough (11) is used for receiving bullets. The recess (12) has a lateral opening (121), a top portion (122), and a bottom portion (123). The recess (12) is provided to receive an air cartridge (1) between the top portion (122) and the bottom portion (123). The lateral opening (121) is used for the air cartridge (1) being put therethrough. The hole (13) passes through the bottom portion (123) and communicates with the recess (12). A diameter of the hole (13) is smaller than a maximum diameter of the air cartridge (1). In other words, the air cartridge (1) cannot pass through the hole (13) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com