Stirring device for asphalt mixture

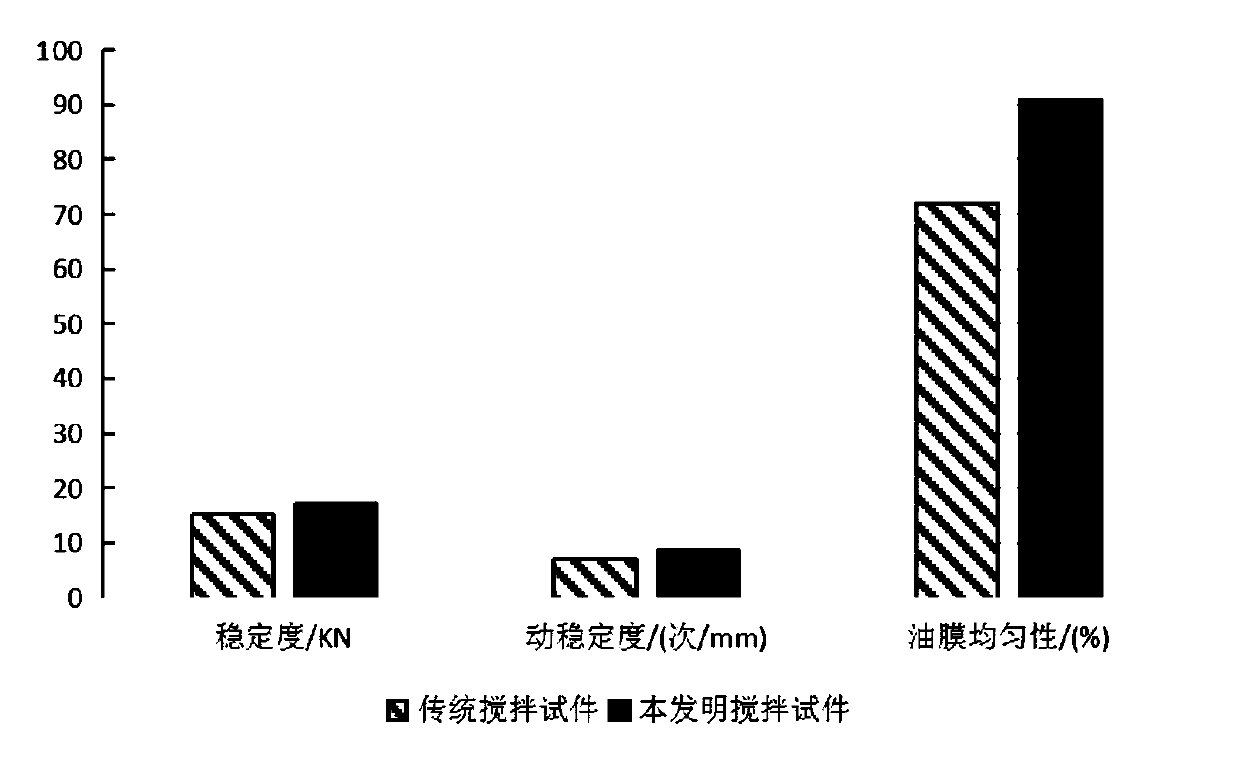

The technology of asphalt mixture and mixing device is applied in the field of asphalt mixture, which can solve the problems of unreasonable addition method of aggregate, asphalt and mineral powder, poor mixing quality of asphalt mixture, unreasonable movement state of coarse and fine aggregate, etc. Achieve the effect of improving production efficiency and road performance, increasing effective spraying area, improving mixing quality and mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] Such as Figure 6 As shown, a kind of asphalt mixing device proposed by the present invention, it comprises from top to bottom successively: feed inlet 8, air blast type slag powder spraying device 1; 23; semi-ellipsoidal primary mixing bin 3; half bin type rotating stirring device 4; primary mixing bin burner; circular frustum-shaped slidable vertical support device 5; primary discharge port 45; secondary mixing bin 6; double horizontal shafts Paddle stirring device 7, secondary stirring bin burner; discharge port 9.

[0050] The detailed size, structure and function of the device are introduced as follows:

[0051] The feed inlet 8 is located at the upper left of the primary mixing chamber 3, and is in the shape of a trapezoidal groove, the inclined surface is 40°-50° from the horizontal direction, and the junction with the primary mixing chamber 3 is arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com