A temperature-sensitive sodium alginate/cellulose ether composite hydrogel and its preparation method and application

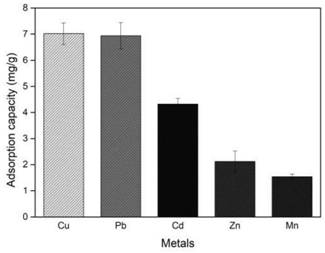

A temperature-sensitive, composite hydrogel technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem that gel biocompatibility and degradability cannot be fundamentally improved, etc. problems, to achieve the effects of convenient recycling, increased adsorption capacity, and high adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

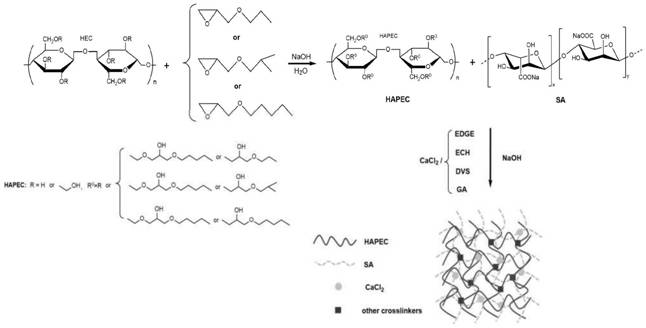

[0037] Such as figure 1 Shown, temperature-sensitive sodium alginate / cellulose ether composite hydrogel preparation method:

[0038] (1) Preparation of 2-hydroxy-3-pentoxypropyl cellulose:

[0039] Add 5 g of cellulose into a 100 ml three-necked flask, add 12.5 ml of water to disperse, stir and heat to 70°C. 0.58 g of 40% sodium hydroxide was added dropwise in a three-neck flask, and alkalized at 70° C. for 1 h. Then, 5 grams of pentyloxyglycidyl ether was added dropwise to the reaction liquid after alkalization, and reacted at 70° C. for 9 hours. After completion of the reaction, dilute with 100 milliliters of water and cool to room temperature, neutralize with hydrochloric acid to a pH value of 7, then put it into a dialysis bag with a molecular weight of 7000-14000 and put it into a deionized medium for dialysis. The conductivity of the deionized water is less than 10 μs / cm was the completion of dialysis, and most of the water was removed with a rotary evaporator, and th...

Embodiment 2

[0061] This example is basically the same as Example 1, except that in (3), the crosslinking agent is 200 μL epichlorohydrin and 900 μL calcium chloride solution, and the specific reaction conditions are shown in Table 1;

[0062] The composite gel obtained in the embodiment was tested according to the above application examples, and the adsorption capacity of the sodium alginate / cellulose ether composite gel SC-2 to heavy metal ions was 251.2 mg / g; the mass of the SC-2 gel after recovery and regeneration It was 0.267g, and the recovery efficiency was 89.0%.

[0063] Table 1

[0064]

Embodiment 3

[0066] This embodiment is basically the same as Example 1, except that in (3), the amount of NaOH is 0.3g (40%), the cross-linking agent is 50 μL vinyl sulfone and 60 μL calcium chloride solution, and the reaction temperature is 20° C. For 0.5h, the specific reaction conditions are shown in Table 2;

[0067] The composite gel obtained in the embodiment was tested according to the above application examples, and the adsorption capacity of the sodium alginate / cellulose ether composite gel SC-3 to heavy metal ions was 138.9 mg / g; the mass of the SC-3 gel after recovery and regeneration was It is 0.289g, and the recovery efficiency is 96.3%.

[0068] Table 2

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com