Nano controlled-release fertilizer and preparation method therefor

A controlled-release fertilizer and nanotechnology, applied in fertilization methods, nitrogen fertilizers, fertilization devices, etc., can solve problems such as being easily washed away by water, prolonging fertilizer efficiency, and immature and stable processing technology of nano-fertilizers. Technological development, the effect of improving absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

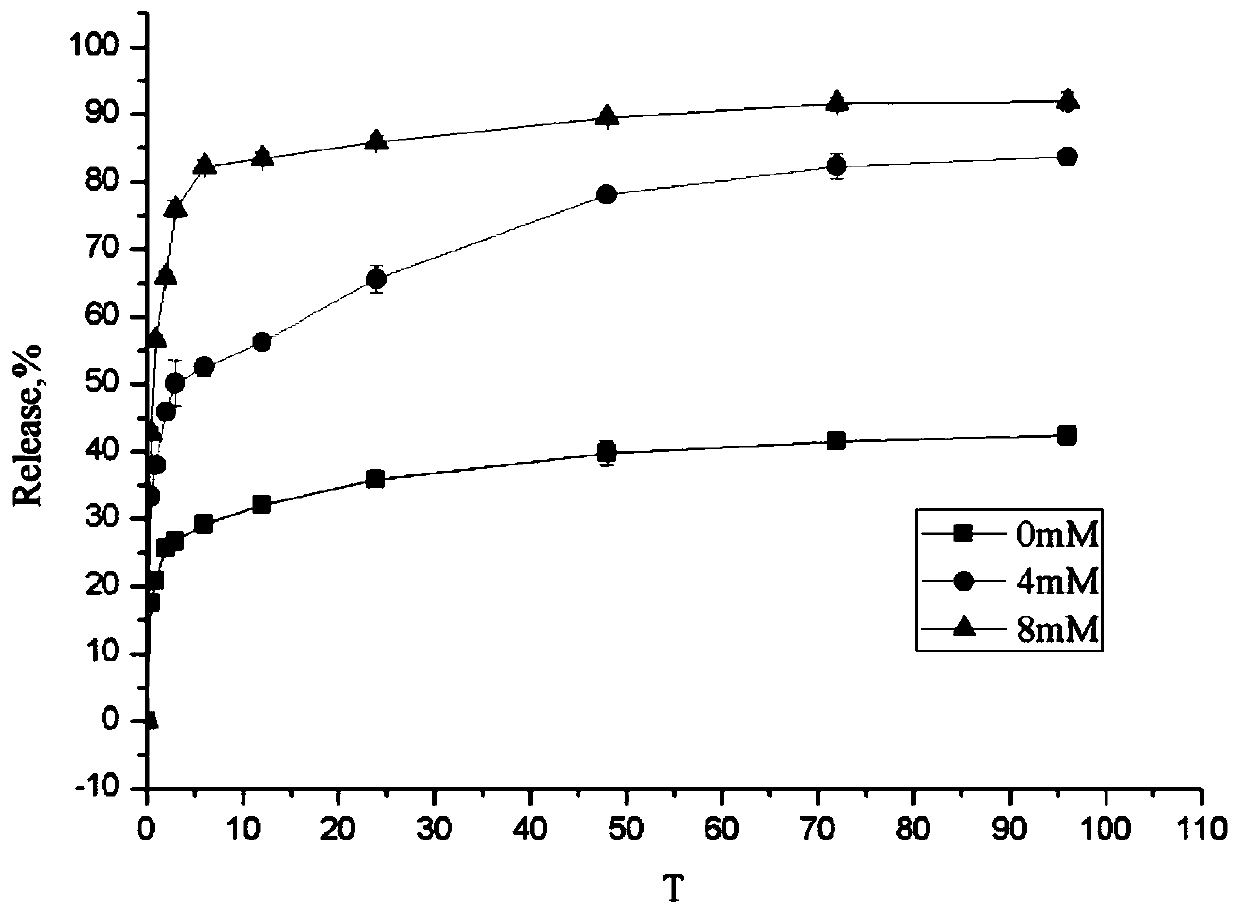

[0064] The second aspect of the present invention provides a method for preparing the above-mentioned nanometer controlled-release fertilizer. The steps include: adsorbing the fertilizer into a sulfhydryl-functionalized nanocarrier through negative pressure to obtain a sulfhydryl-functionalized nanocarrier loaded with fertilizer, and then modifying the sulfhydryl group into a sulfhydryl-functionalized nanocarrier. The surface mesopores and lumen ports of the fertilizer-loaded thiol-functionalized nanocarriers were blocked by the modified polysaccharide with the sulfhydryl group.

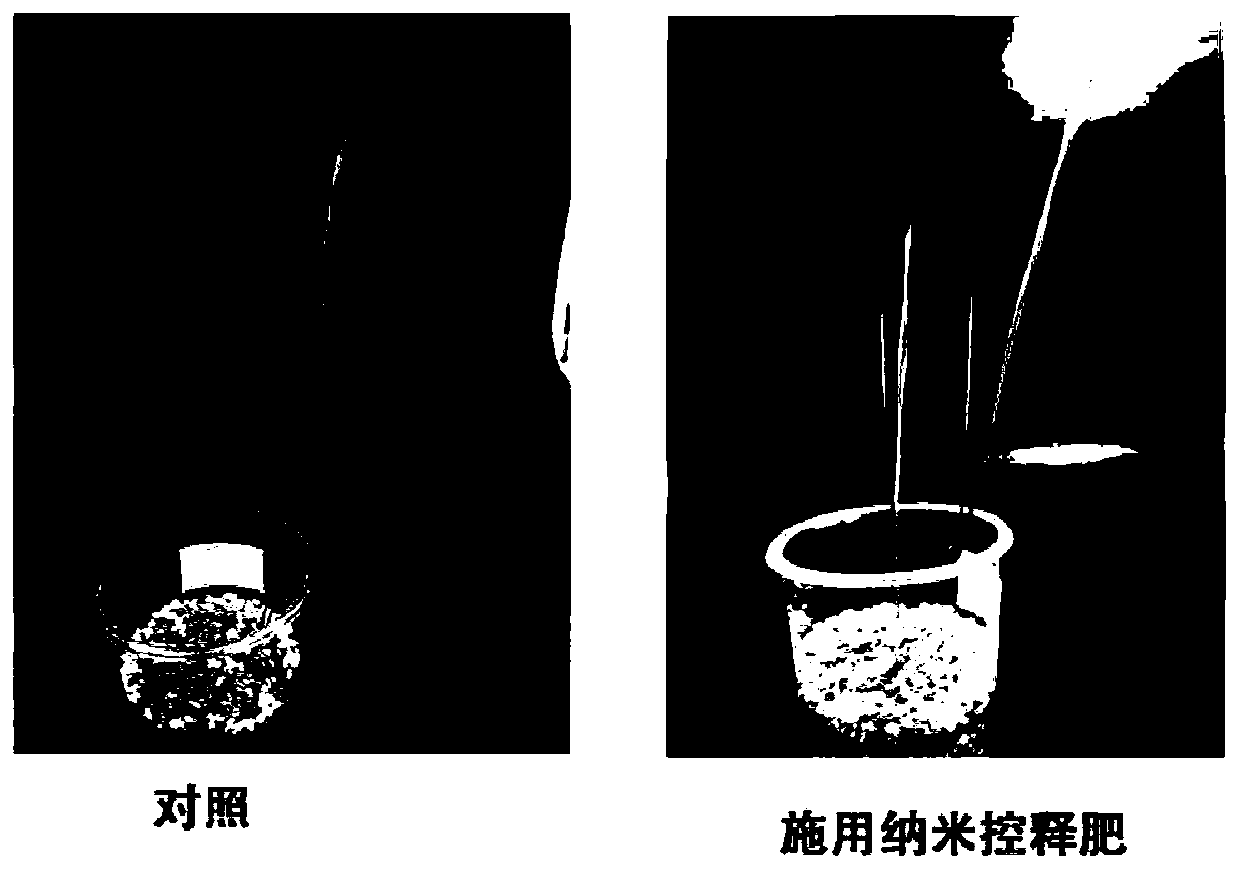

[0065] The third aspect of the present invention provides a method for using the above-mentioned nano-controlled-release fertilizer, wherein the nano-controlled-release fertilizer powder is suspended in water and sprayed on the foliage of plants.

Embodiment 1

[0069] Embodiment 1 provides a nanometer controlled-release fertilizer, which is assembled from fertilizer core particles and an outer coating, wherein the fertilizer core particles are sulfhydryl functionalized nanocarriers loaded with fertilizers; the outer coating is modified by a sulfhydryl modifier. polysaccharides.

[0070] The preparation steps of the nanometer controlled-release fertilizer include: adsorbing the fertilizer into the sulfhydryl-functionalized nano-carrier through negative pressure to obtain the sulfhydryl-functionalized nano-carrier of the fertilizer, and then modifying the polysaccharide with a sulfhydryl modifier to affect the sulfhydryl-functionalized nano-carrier of the fertilizer. The surface mesopores and lumen ports of the carrier were blocked.

[0071] The specific preparation steps include:

[0072] Preparation of S1 thiol-functionalized nanocarriers:

[0073] Weigh 2.5 mL of halloysite nanotube powder and disperse it in 100 mL of toluene solu...

Embodiment 2

[0081] Embodiment 2 provides a kind of nanometer controlled-release fertilizer, and its specific implementation is the same as that of embodiment 1, the difference is that the toluene described in S1 is replaced with dehydrated ethanol, and 3-mercaptopropyl triethoxysilane is replaced. Into 3-mercaptopropyl trimethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com