Filtering method and device using honeycomb ceramic membrane

A technology of honeycomb ceramics and membrane filtration, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of lack of in-depth research and improvement of honeycomb ceramic membranes, achieve investment cost reduction, reduce membrane pollution, fill The effect of high installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

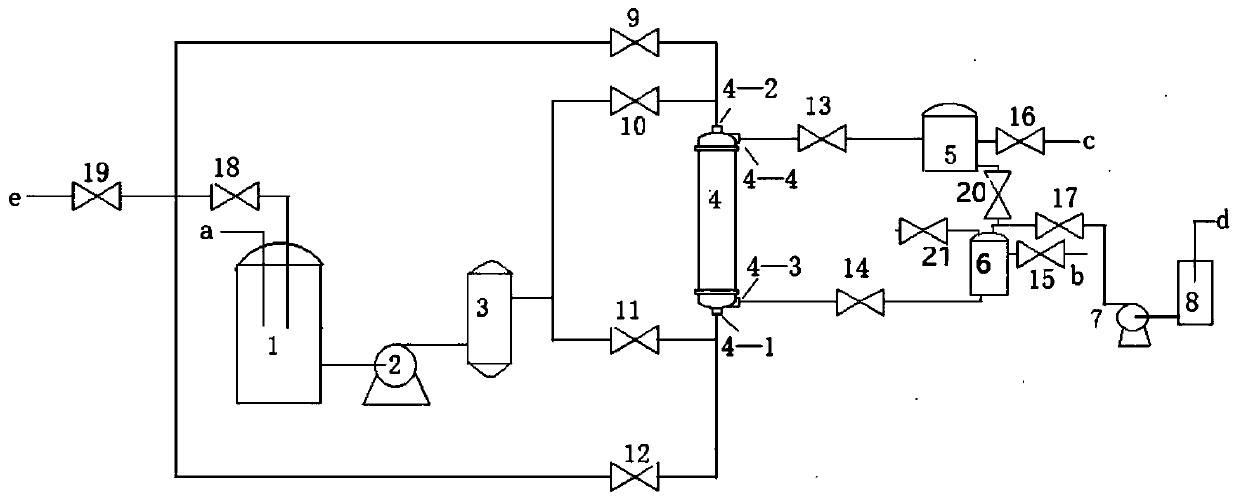

[0042] Such as figure 1 As shown, a honeycomb ceramic membrane filtration device includes a raw liquid tank, a feed pump, a coarse filter, a concentrated liquid return main pipe, a honeycomb ceramic membrane module, a recoil liquid tank, a dissolved air tank and a recoil gas source;

[0043] The top of the ceramic membrane module is equipped with an upper inlet and outlet and a supernatant liquid inlet, and the bottom of the ceramic membrane module is equipped with a lower inlet and outlet and a recoil inlet;

[0044] The inlets of raw liquid tank, feed pump and coarse filter are connected in turn through pipelines; the outlet of coarse filter is connected with feeding pipe, which is branched into upper feeding pipe and lower feeding pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com