Control system for hydraulic-mechanical combined braking of explosion-proof vehicle in coal mine

A control system, explosion-proof vehicle technology, applied in the direction of brakes, vehicle components, brake transmissions, etc., can solve the problems of brake overheating, excessive wear of friction plates, oil leakage due to seal failure, etc., to increase reliability and reduce safety accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

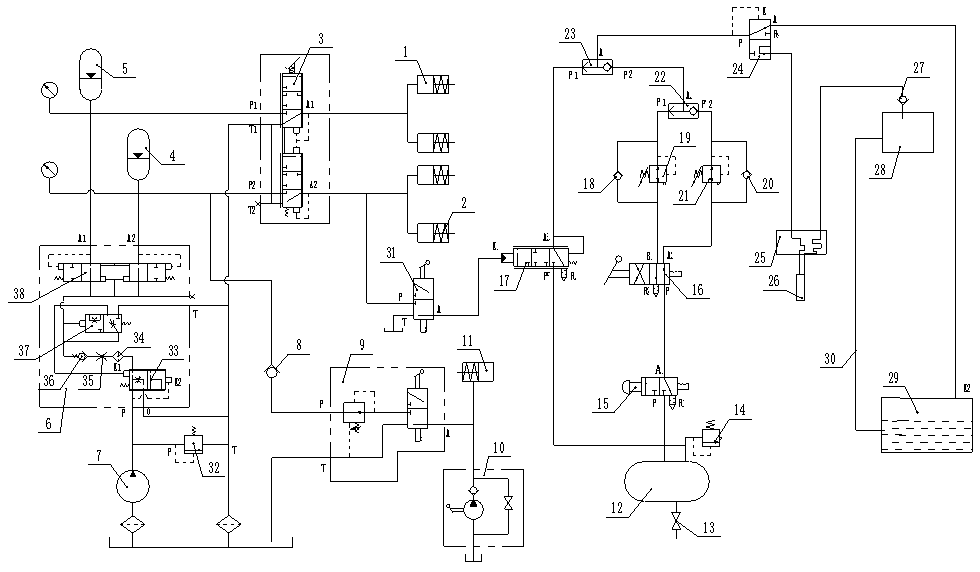

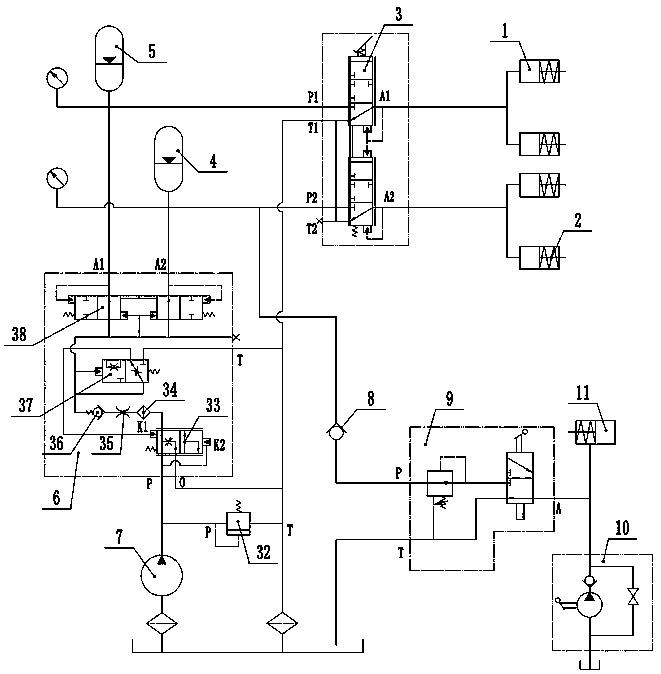

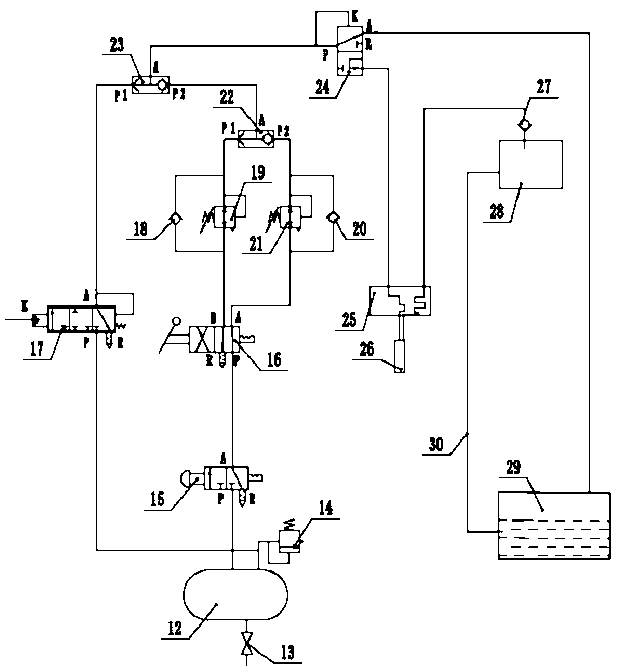

[0013] A hydraulic-mechanical combined braking control system for underground explosion-proof vehicles in coal mines includes a mechanical braking control system and a hydraulic braking control system.

[0014] The mechanical brake control system includes series double-circuit brake valve 3, accumulator I4, accumulator II5, liquid charging valve 6, hydraulic pump 7, one-way valve I8, parking brake valve 9, manual pump 10 and The safety valve 32 and the pressure oil of the hydraulic pump 7 are divided into two paths, one path is connected to the P port of the filling valve 6, and the two outlets A1 and A2 of the filling valve 6 are respectively connected to the accumulator I4 and the accumulator II5; One way is connected to the P port of the safety valve 32, the T port of the safety valve 32 is respectively connected to the oil tank and the T1 port of the series double circuit brake valve 3, and the A1 port and the A2 port of the series double circuit brake valve 3 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com