Supercritical extraction technology imitating ultrasonic high-speed separation

A high-speed separation and supercritical technology, applied in co-current extraction, solvent extraction, separation methods, etc., can solve the problems of lower drug extraction efficiency and longer time, and achieve the goal of improving safety, stability, efficiency, and circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

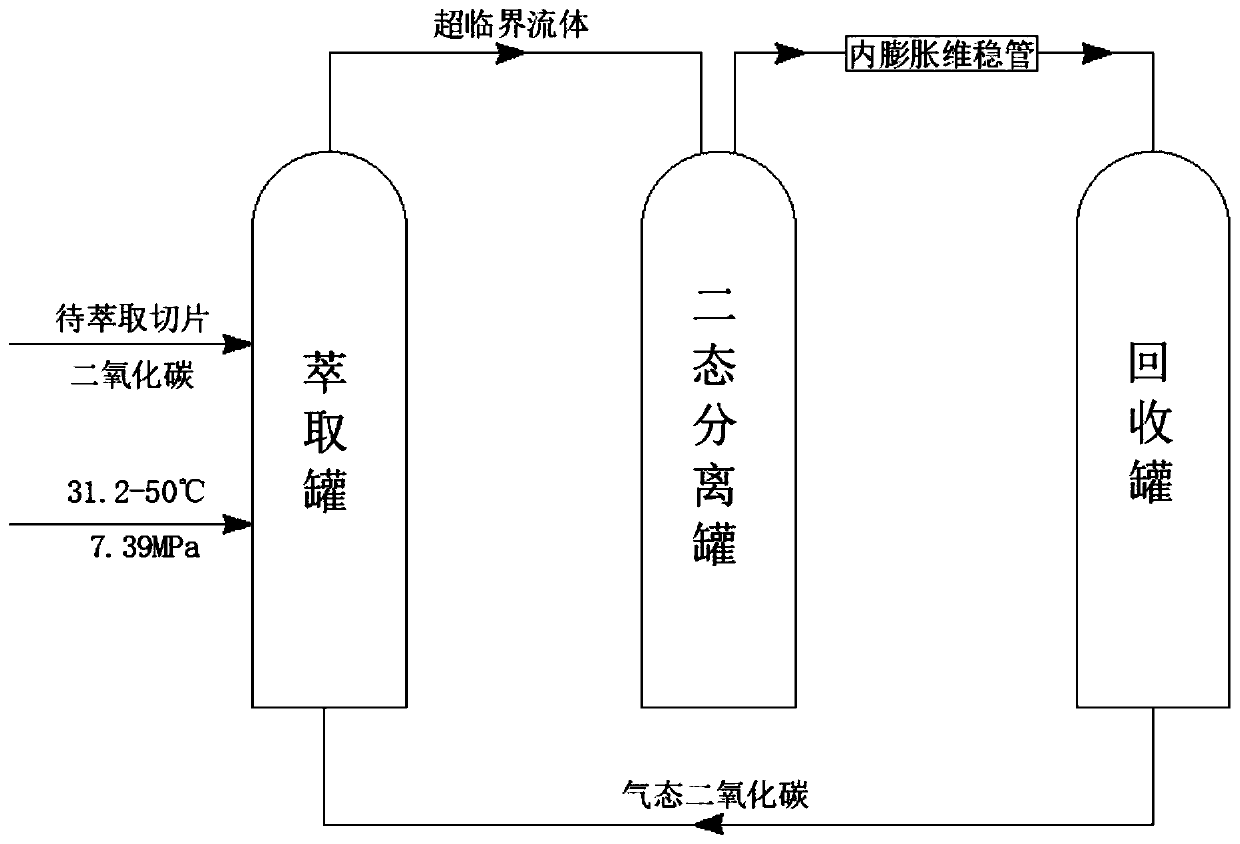

[0052] see figure 1 , a supercritical extraction process imitating ultrasonic high-speed separation, comprising the following steps:

[0053] S1. First, slice the extract to be extracted, and then wash and dry to obtain small-volume slices to be extracted for later use;

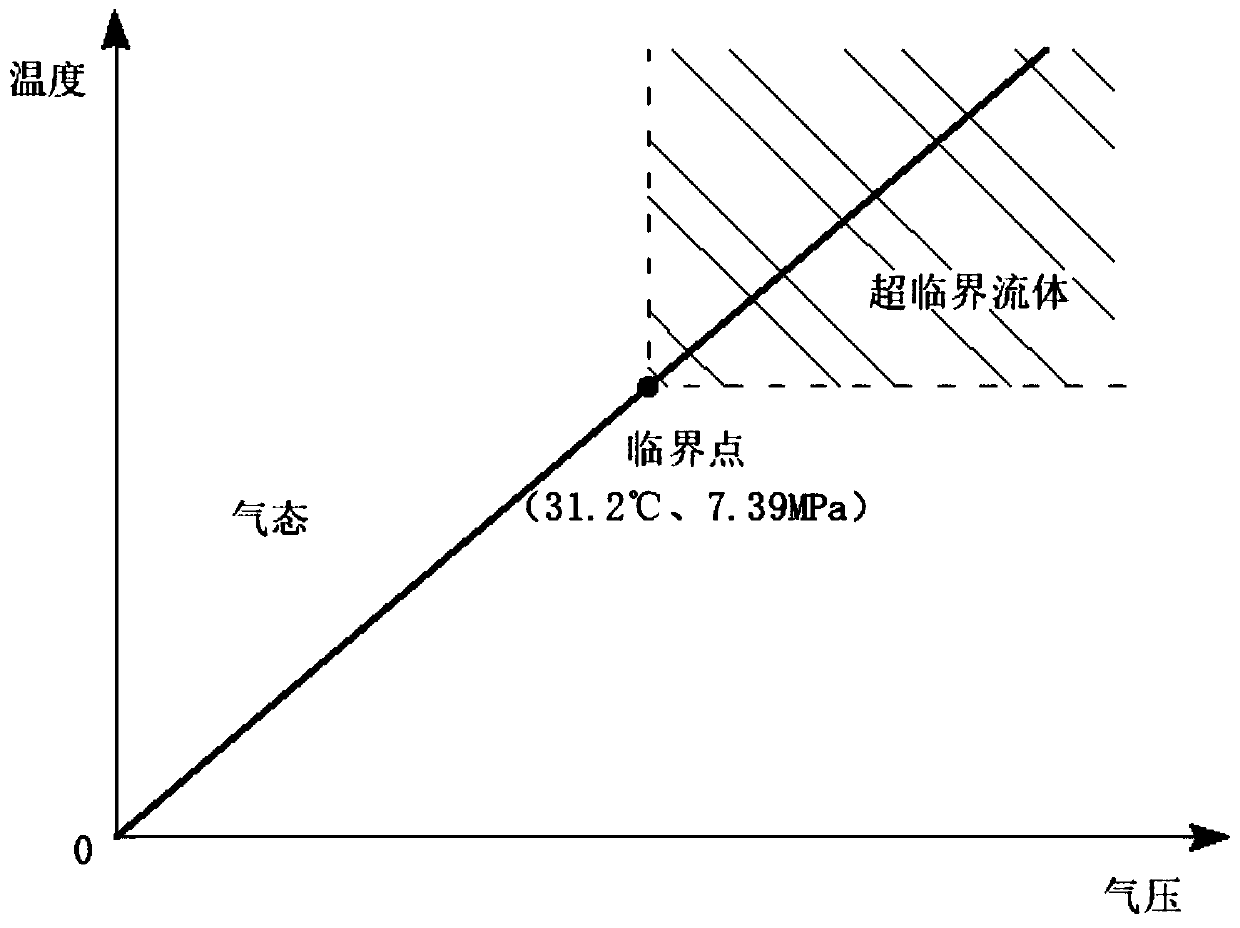

[0054] S2. Pass the small-volume slices to be extracted and carbon dioxide into the extraction tank, and adjust the temperature and pressure of the extraction tank so that the carbon dioxide is in a supercritical fluid state, allowing it to diffuse and dissolve in the small-volume slices to be extracted. Together, a binary intermediate is obtained;

[0055] S3. After extracting for a period of time, the binary intermediate is passed into the binary separation tank, and the operation of reducing the pressure to atmospheric pressure and raising the temperature is carried out, so that the carbon dioxide returns to the gaseous state;

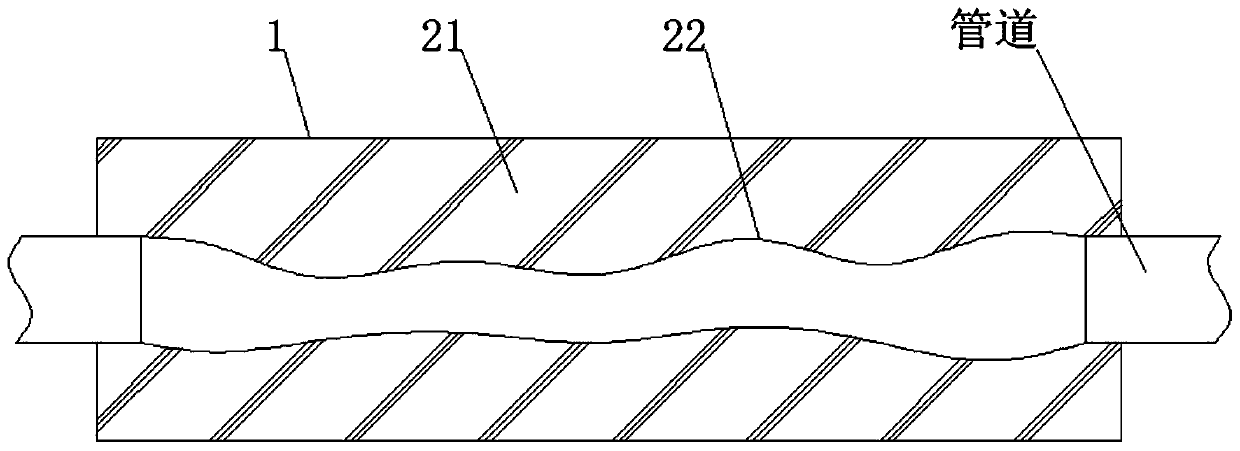

[0056] S4. During the process of recovering the gaseous state of carbon diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com