Ball permanent magnet coupler

A permanent magnet coupling, ball technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electromechanical device, etc., can solve the instability of transmission, limit the use range and development of magnetic coupling, installation accuracy Ask for advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

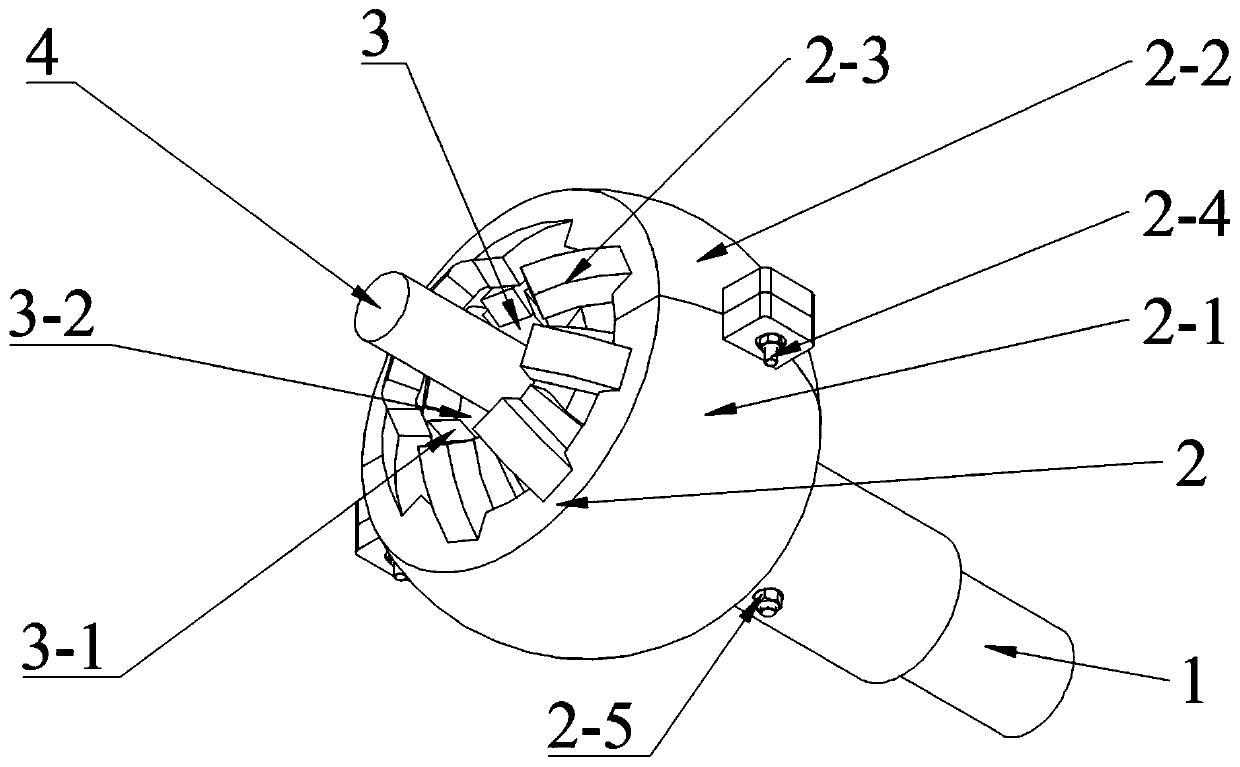

[0038] Attached below figure 1 - attached Figure 10 The ball type permanent magnet coupling disclosed in this embodiment is further described;

[0039] Refer to attached figure 1 As shown, the ball-type permanent magnet coupling is mainly composed of an outer rotation body 2 at the input end and an inner rotation body 3 at the output end. The outer rotation body 2 is connected to the input shaft 1, and the inner rotation body 3 is connected to the output shaft 4.

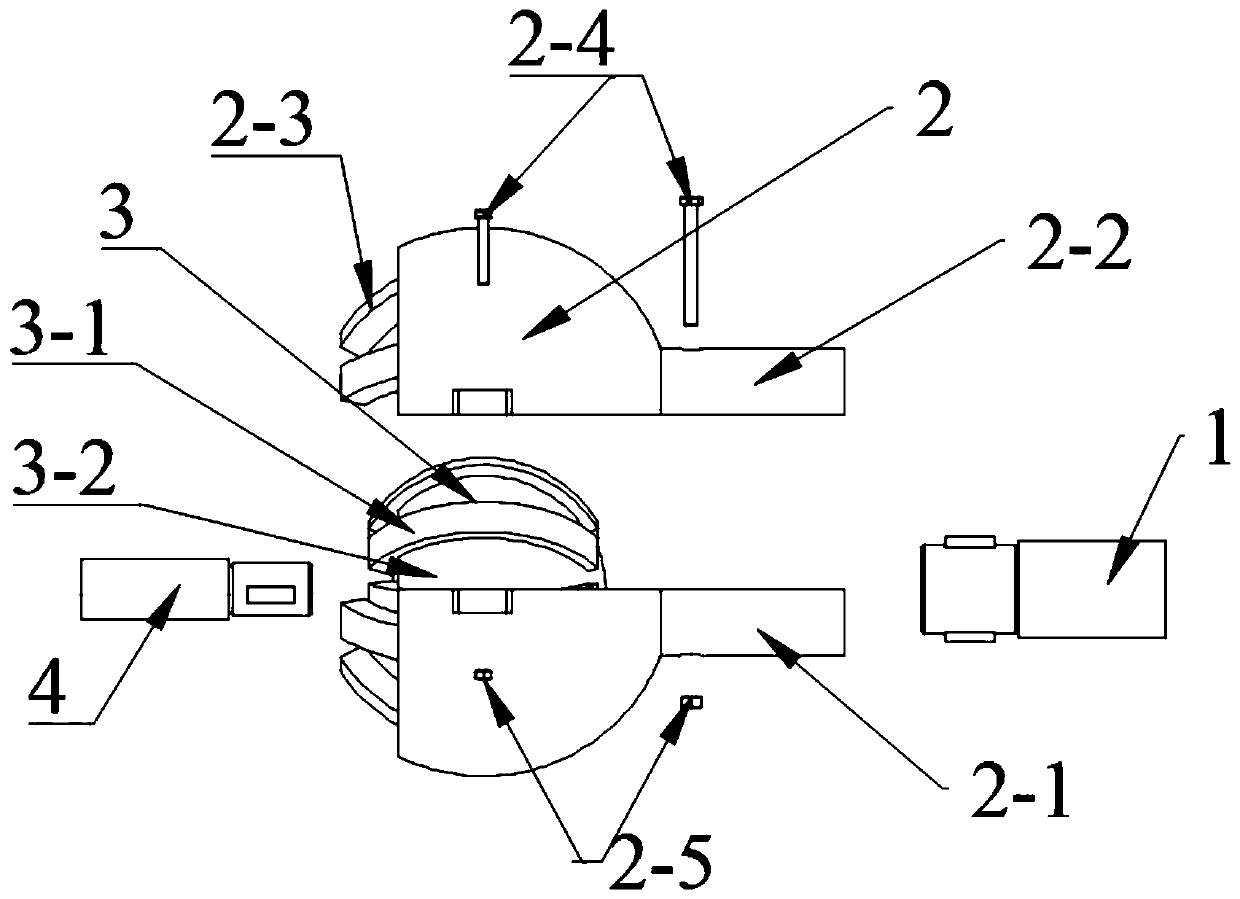

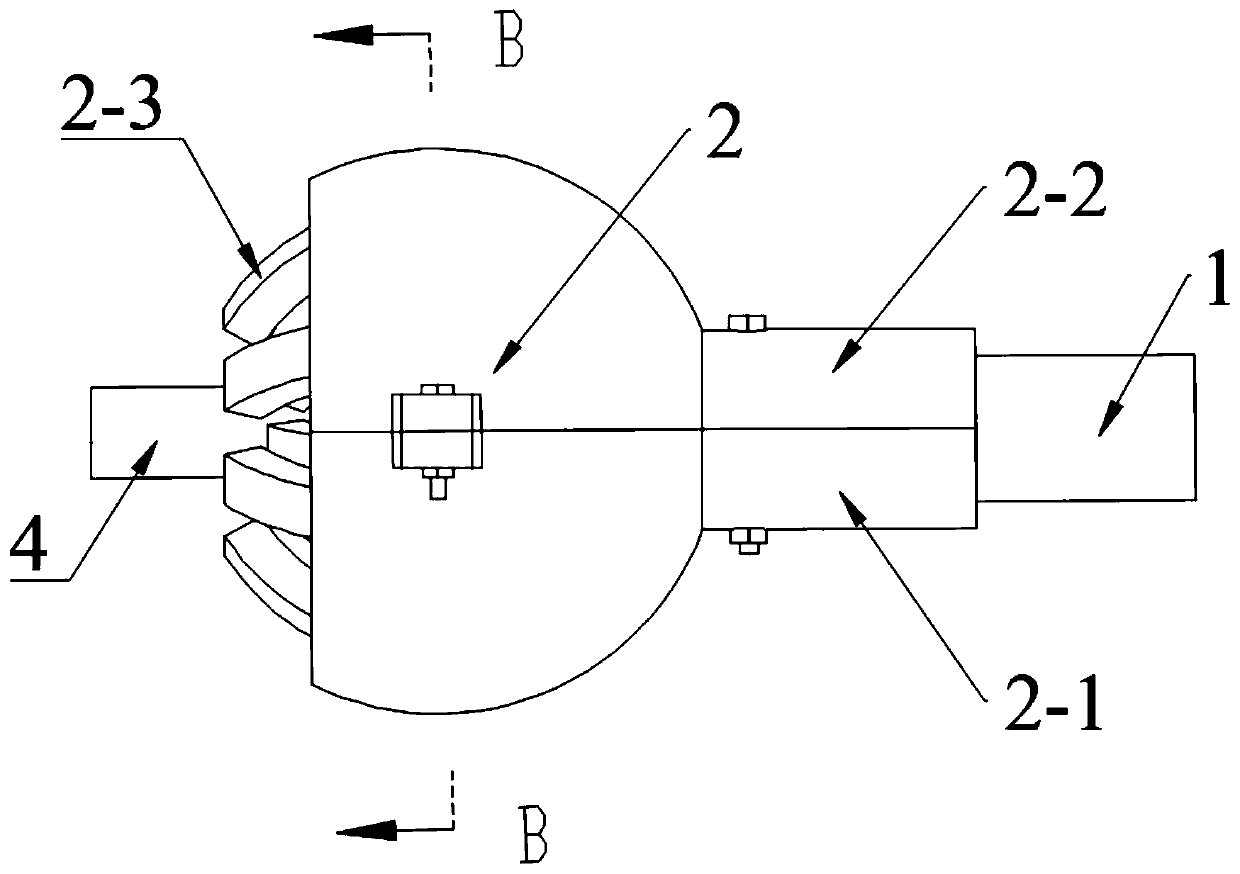

[0040] Such as figure 2 As shown, the outer rotor 2 is composed of a hollow spherical outer rotor and an outer rotor magnet. For the convenience of assembly, the outer rotor is divided into upper and lower outer rotors, and the single piece is spoon-shaped. The outer rotor 2-1, the outer rotor 2-2 are relatively arranged, and the outer rotating magnets 2-3 are evenly arranged on the inner surfaces of the outer rotor 2-1 and the outer rotor 2-2;

[0041] Such as Figure 6 As shown, the outer rotor includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com