Socks air duct system used in factory and installation method of socks air duct system

A cloth bag air duct and factory technology, applied in air conditioning systems, heating methods, pipeline layout, etc., can solve the problems of reducing the air quality of the factory workshop, failing to effectively improve the air quality of the factory workshop, and unfavorable staff working for a long time. Low construction difficulty, good ventilation effect, and the effect of improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

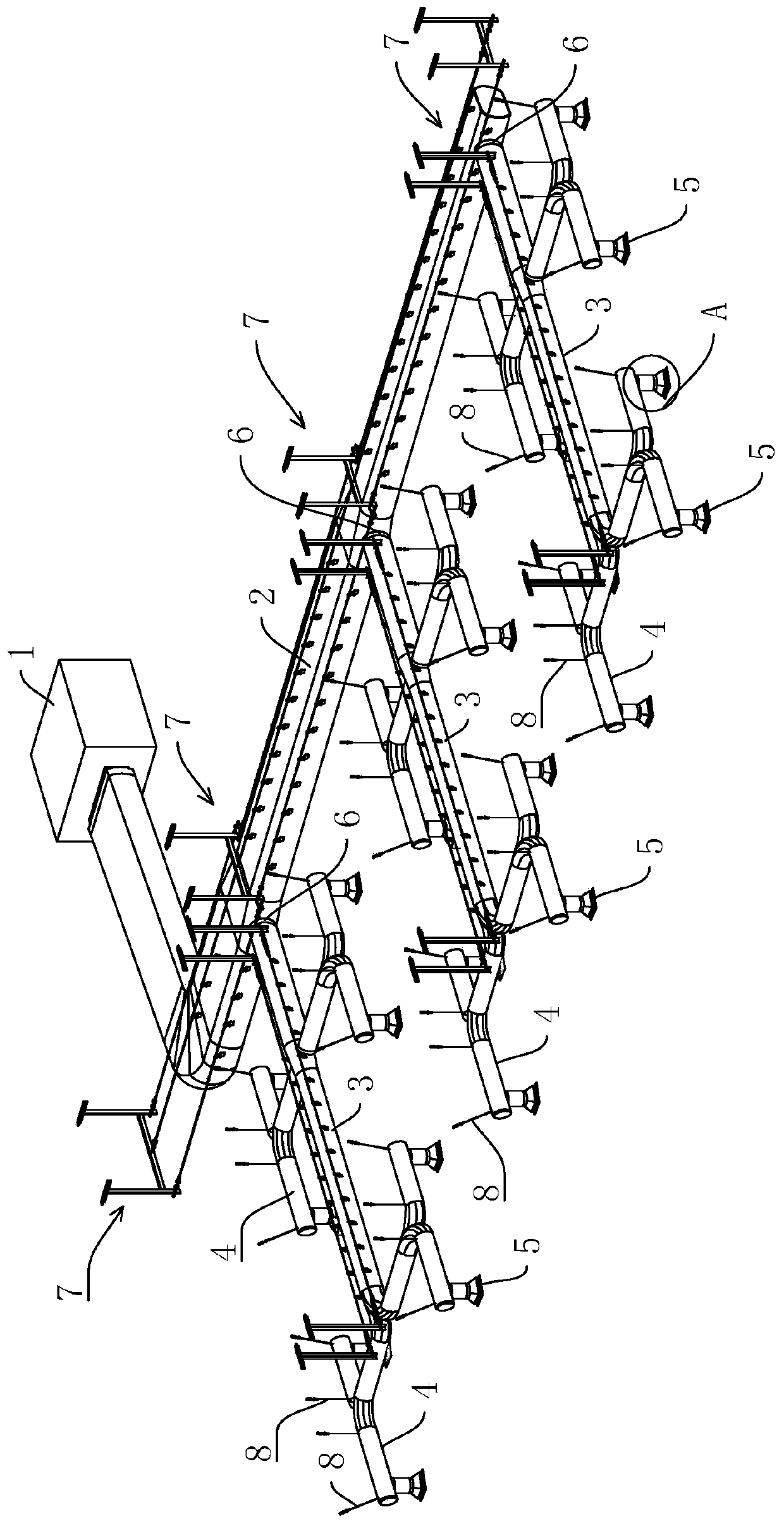

[0046] refer to figure 1 , is a factory cloth bag air duct system disclosed by the present invention, including: static pressure box 1, main road air duct 2, branch air duct 3, tail road air duct 4, air outlet structure 5, fragrance unit 6, suspension structure 7 and sling structures 8 .

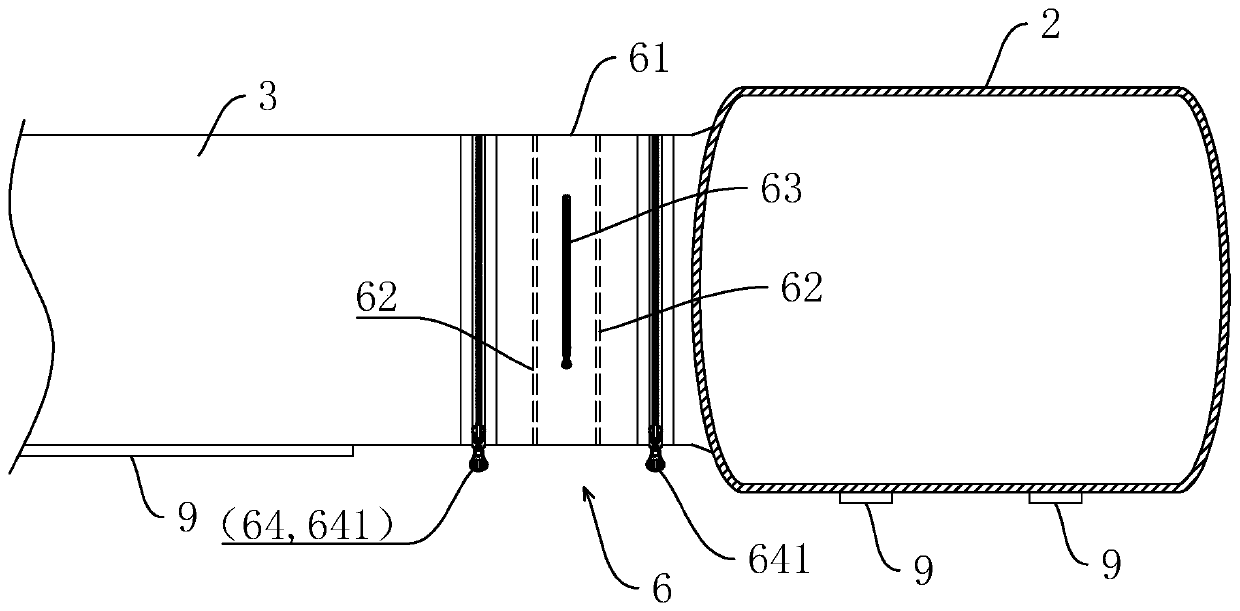

[0047] The main air duct 2 is connected to the external air supply system through the static pressure box 1. There are multiple branch air ducts 3. The branch air duct 3 is connected to the main air duct 2 through the fragrance unit 6. The fragrance unit 6 is set There are spices and detachable installation, the tail air duct 4 is provided with multiple pieces, the tail air duct 4 is connected with the branch air duct 3, and the lower surface of the end of the tail air duct 4 is connected with the air outlet structure 5.

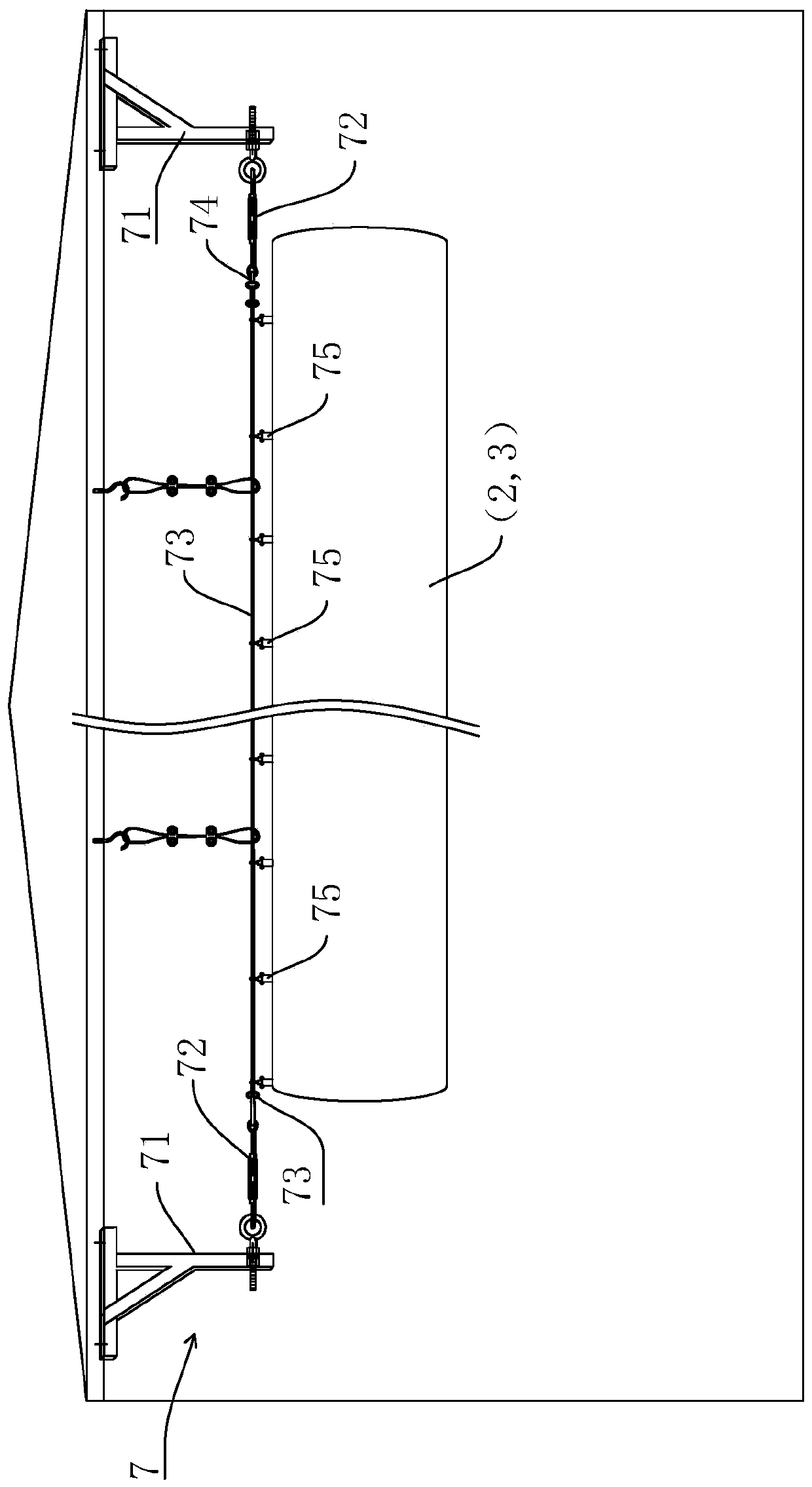

[0048] The top of the suspension structure 7 is connected and fixed to the roof, the main air duct 2 and the branch air duct 3 are suspended at the bottom of the suspensi...

Embodiment 2

[0059] refer to figure 1 and Figure 6 , is a factory cloth bag air duct system disclosed in the present invention, the difference from Embodiment 1 is that the detachable connector 64 is specifically a Velcro 642, and the Velcro 642 is arranged around the tubular bag 61 in a circle. Velcro 642 is easy to purchase, low in cost, and easy to sew. At the same time, when the staff removes the fragrance unit 6, the operation is very convenient. Compared with the zipper structure, the Velcro 642 has a hidden effect and good sealing performance, so Prevent fresh air from escaping from this connection.

Embodiment 3

[0061] refer to figure 1 and Figure 7 , is an installation method of the bag air duct system disclosed in the present invention, based on the factory bag air duct system as described in Embodiment 1 or Embodiment 2, the method includes three steps of S1, S2, and S3.

[0062] S1: Multiple sets of suspension structures 7 and multiple sets of sling structures 8 are fixedly installed on the roof. One set of suspension structures 7 is arranged vertically, and the other suspension structures 7 are arranged horizontally. Each set of sling structures 8 is provided with two, adjacent two The sling structures 8 are arranged obliquely.

[0063] S2: Suspend and fix the main air duct 2 on the bottom of the vertically arranged suspension structure 7, suspend and fix the branch air duct 3 on the bottom of the horizontally arranged suspension structure 7, and suspend the tail air duct 4 on multiple sets of hanging structures. At the bottom of the cable structure 8, the air outlet structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com