Firewood stove inner sleeve with multiple combustion chambers

A combustion chamber and inner sleeve technology, applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of affecting air quality, increasing fuel consumption, and unreasonable furnace structure, etc., so as to improve the channel space and increase the pile of firewood height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

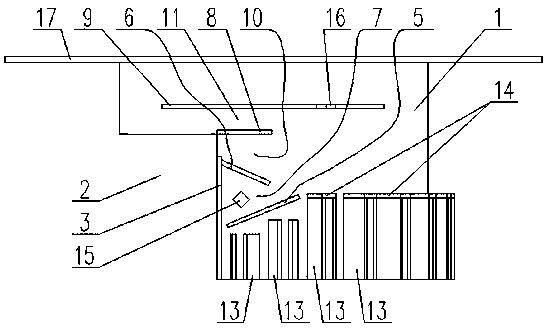

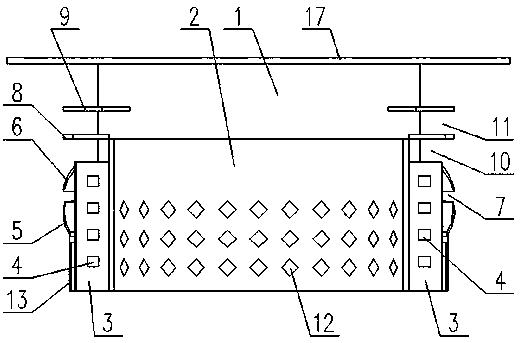

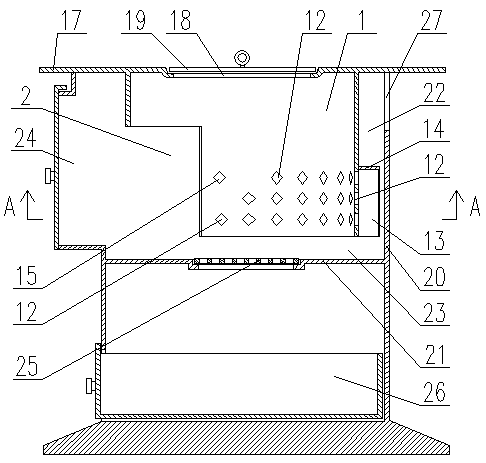

[0021] Depend on figure 1 , figure 2 and Figure 4 As shown, a wood stove inner cover with multiple combustion chambers, it includes an inner cover body 1, on which the inner cover body 1 is provided with an inner firewood inlet port 2, and the inner firewood inlet port 2 of the inner cover body 1 The two sides of the mouth 2 are respectively provided with a baffle 3, and the first smoke hole 4 is opened on the baffle 3, and the two sides of the inner sleeve body 1 behind the baffle 3 are respectively provided with an upwardly inclined first partition 5 And the second partition 6 inclined downwards, the upper end of the second partition 6 is connected with the baffle 3, and the first flue guide 7 is formed between the first partition 5 and the second partition 6. A second smoke hole 15 is opened on the inner casing body 1 between the first partition 5 and the second partition 6 . The inner casing body 1 above the baffle plate 3 is respectively provided with a third dividin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com