Production process of degradable paper bag

A production process and technology of paper bags, applied in the field of production process of degradable paper bags, can solve problems such as inconvenience, paper bags have no waterproof function, etc., and achieve the effects of increasing molecular weight, improving environmental protection performance, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of production technology of degradable paper bag, comprises the steps:

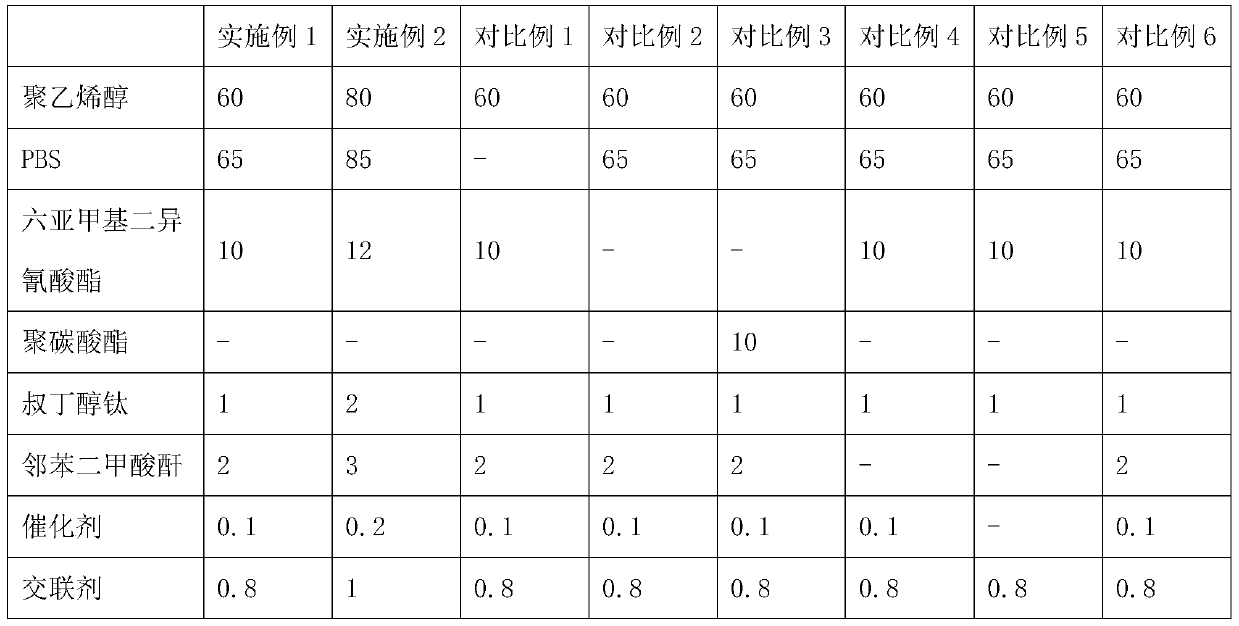

[0042] S1. Weigh the required components by weight, initially mix 60 parts of polyvinyl alcohol, 10 parts of hexamethylene diisocyanate and 1 part of titanium tert-butoxide, then add 2 parts of phthalic anhydride and 0.1 part of 4 -Dimethylaminopyridine, further mixed, and finally added 0.8 parts of ethylenediamine, stirred and mixed evenly, to prepare a toughened film for subsequent use; the contents of each component are shown in Table 1 below;

[0043] S2. Using a laminating machine to heat-melt the toughened film of S1 and evenly coat and coat it on the surface of the wrapping paper. The toughened film is hot-melted on the surface of the wrapping paper and bonded to the wrapping paper;

[0044] S3. Use a laminating machine to evenly spray and coat 65 parts of PBS on the toughening film after hot-melting to form a waterproof layer. The waterproof layer is combined with the toughening film...

Embodiment 2

[0047] A kind of production technology of degradable paper bag, comprises the steps:

[0048] S1. Weigh the required parts by weight, initially mix 80 parts of polyvinyl alcohol, 12 parts of hexamethylene diisocyanate and 1-2 parts of titanium tert-butoxide, then add 3 parts of phthalic anhydride and 0.2 1 part of 4-dimethylaminopyridine, mixed further, and finally added 1 part of ethylenediamine, stirred and mixed uniformly to prepare a toughened film for subsequent use; the contents of each component are shown in Table 1 below;

[0049] S2. Using a laminating machine to heat-melt the toughened film of S1 and evenly coat and coat it on the surface of the wrapping paper. The toughened film is hot-melted on the surface of the wrapping paper and bonded to the wrapping paper;

[0050] S3, using a laminating machine to evenly spray and coat 85 parts of PBS on the toughened film after hot-melting to form a waterproof layer, and the waterproof layer is combined with the toughened film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com