Method for preparing potassium chloride from low-grade potassium resource ore at low energy consumption

A low-grade, potassium chloride technology, applied in the field of inorganic salts, can solve the problems of hot-melt equipment scaling, poor economic benefits, and high energy consumption, and achieve low raw material grade requirements, optimized heat storage performance, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

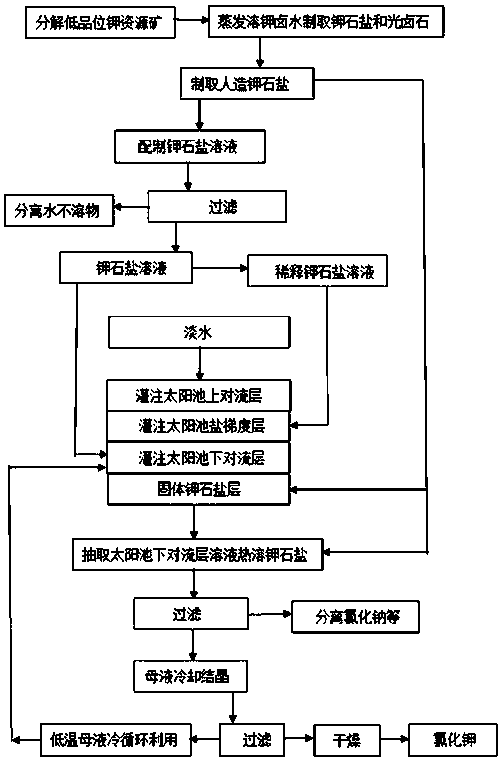

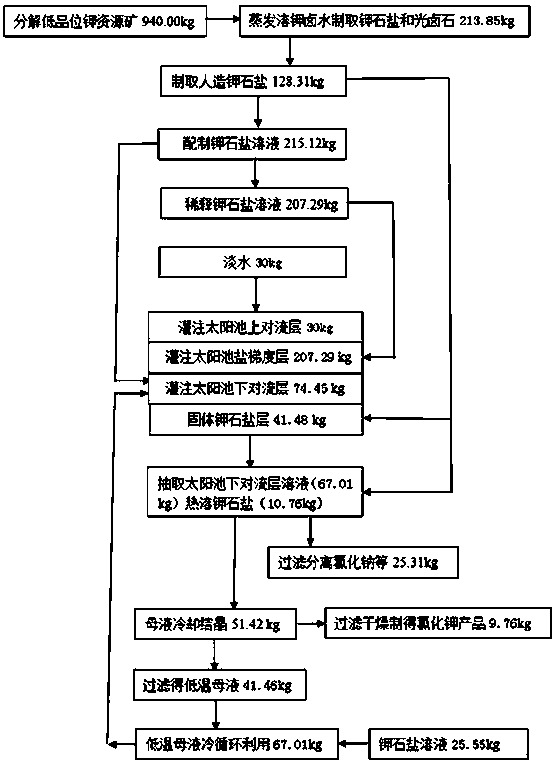

[0023] Example 1, such as figure 1 , figure 2 As shown, the present invention provides a kind of method that utilizes low-grade potassium resource ore to prepare potassium chloride with low energy consumption, and concrete technical scheme comprises following preparation steps:

[0024] Step 1: Decompose low-grade potassium resource ore. Take 940.00kg of flotation tailings, add water to dissolve, the solid-to-liquid ratio is 1:0.8, filter to remove 377.88kg of solid phases such as sediment and undissolved matter, and prepare 562.12kg of potassium-soluble brine for later use;

[0025] The second step: Evaporating potassium-dissolved brine to produce potassium halite and carnallite. Get 562.12kg potassium-dissolving bittern, carry out natural evaporation, filter and make potassium halite and carnallite mixed solid phase 213.85kg, standby;

[0026] The third step: preparation of artificial potash salt. Take 213.85kg of potassium halite and carnallite as a mixed solid phase, ...

Embodiment 2

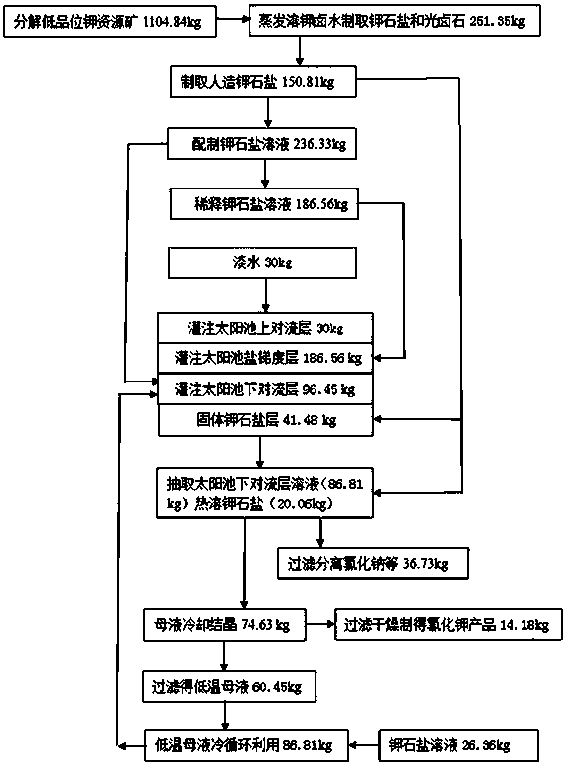

[0036] Example 2, such as figure 1 , image 3 As shown, the present invention provides a kind of method that utilizes low-grade potassium resource ore to prepare potassium chloride with low energy consumption, and concrete technical scheme comprises following preparation steps:

[0037] Step 1: Decompose low-grade potassium resource ore. Take 1104.84kg of flotation tailings, add water to dissolve, the solid-to-liquid ratio is 1:0.9, filter to remove 441.94kg of solid phases such as sediment and undissolved matter, and prepare 662.90kg of potassium-soluble brine for later use;

[0038] The second step: Evaporating potassium-dissolved brine to produce potassium halite and carnallite. Get 662.90kg potassium-dissolving bittern, carry out natural evaporation, filter and make potassium halite and carnallite mixed solid phase 251.35kg, standby;

[0039] The third step: preparation of artificial potash salt. Take 251.35kg of potassium halite and carnallite as a mixed solid phase, ...

Embodiment 3

[0049] Example 3, such as figure 1 , Figure 4 As shown, the present invention provides a kind of method that utilizes low-grade potassium resource ore to prepare potassium chloride with low energy consumption, and concrete technical scheme comprises following preparation steps:

[0050] Step 1: Decompose low-grade potassium resource ore. Take 1115.83kg of flotation tailings, add water to dissolve, the solid-to-liquid ratio is 1:0.7, filter to remove 457.49kg of solid phases such as sediment and undissolved matter, and prepare 658.34kg of potassium-soluble brine for later use;

[0051] The second step: Evaporating potassium-dissolved brine to produce potassium halite and carnallite. Get 658.34kg potassium-dissolving bittern, carry out natural evaporation, filter and make potassium halite and carnallite mixed solid phase 253.85kg, standby;

[0052] The third step: preparation of artificial potash salt. Take 253.85kg of potassium halite and carnallite as a mixed solid phase,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com