Rapid drying device for printed cloth

A rapid drying and cloth technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems that affect the efficiency of cloth dyeing and printing processing, and achieve the effect of saving energy and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

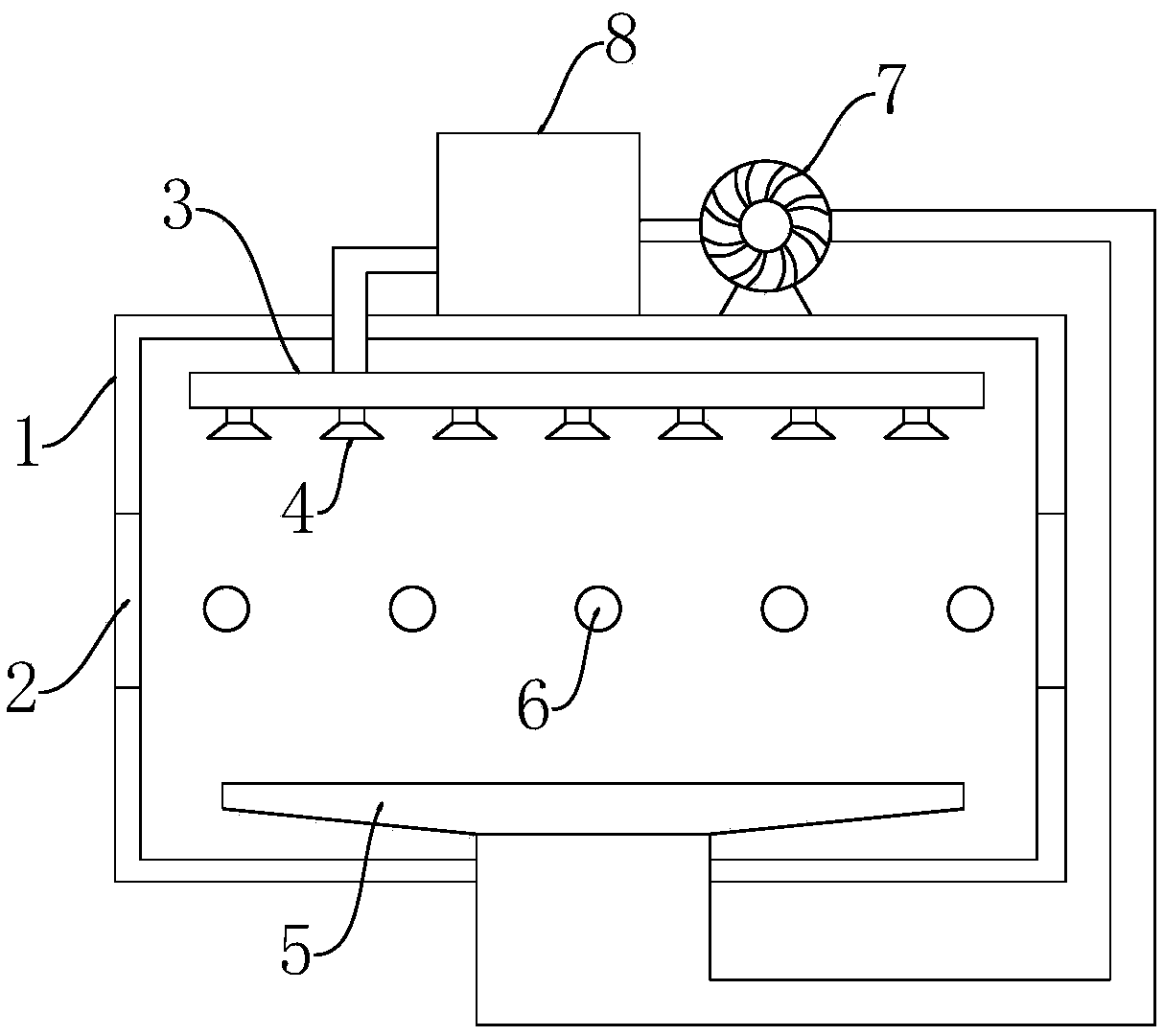

[0012] Such as figure 1 As shown, the device for quickly drying cloth after printing provided in this embodiment includes an oven 1, and the left and right sides of the oven 1 are provided with outlets 2. In order to facilitate the smooth transportation of the cloth in the oven 1, A plurality of cloth guide rollers 6 may be horizontally spaced in the oven 1 , and the cloth guide rollers 6 are rotatably connected with the oven 1 .

[0013] The inner top of the oven 1 is provided with an air supply pipe 3 with both ends closed, and the air supply pipe 3 is provided with a plurality of air nozzles 4, the inner bottom of the oven 1 is provided with a suction hood 5, and the top of the oven 1 is A hot air assembly is provided, the hot air outlet of the hot air assembly communicates with the air supply pipe 3 through a pipe, and the cold air inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com