Intermittent ultrasonic emulsification device for water-based resin

A technology of water-based resin and emulsification device, which is applied in the direction of mixer with rotating stirring device, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increased production cost, low production efficiency, large investment in equipment, etc., and achieve product improvement Quality, improve production efficiency, reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

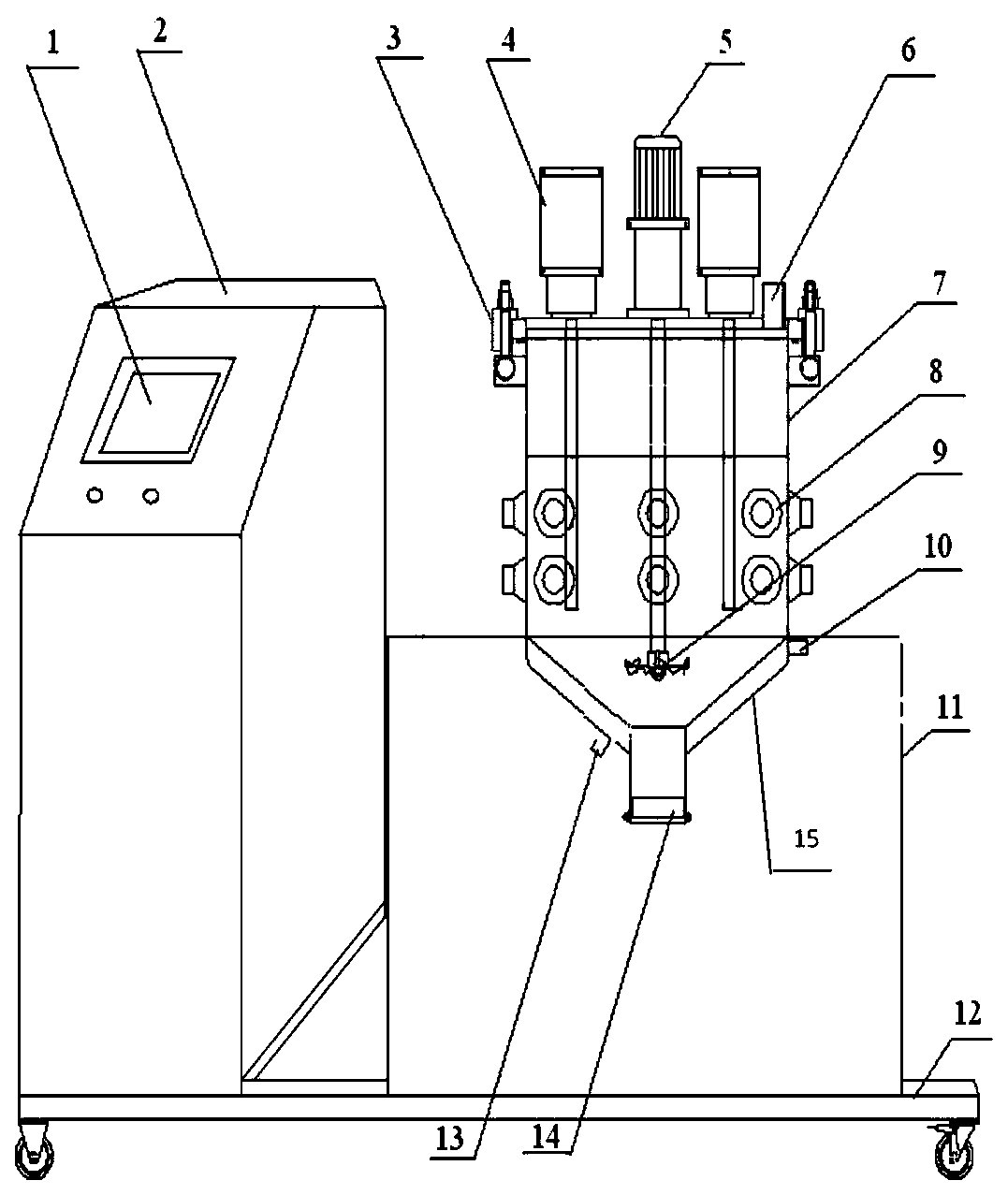

[0013] Such as figure 1 The shown water-based resin intermittent ultrasonic emulsification device includes an emulsification kettle 7, a high-speed disperser 5, a base 12, a support 11 and a control device 2. The reaction kettle 7 is made of stainless steel and is fixedly installed on the base 12 through a bracket 11. The reaction kettle 7 The lower part is provided with a discharge port 14 and a cooling jacket 15, and a kettle cover 3 is installed on the upper end. The kettle cover 3 is provided with a feed inlet, an overflow port 6, an observation port and a temperature detection port. On the cover 3, its dispersing disc 9 extends into the lower part of the inner cavity of the reaction kettle 7. The lower part of the cooling jacket 15 is provided with a cooling water inlet 13, and the upper part is provided with a cooling water outlet 10. The control device 2 is fixedly installed on the base 12. The upper part is provided with There is a touch screen control panel 1, which h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com