Barium ferrite carbon sphere composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material, barium ferrite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as lightness, thinness, width, insufficient absorption strength, narrow absorption frequency band, etc., and achieve good Effects of microwave absorption performance, high raw material cost, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

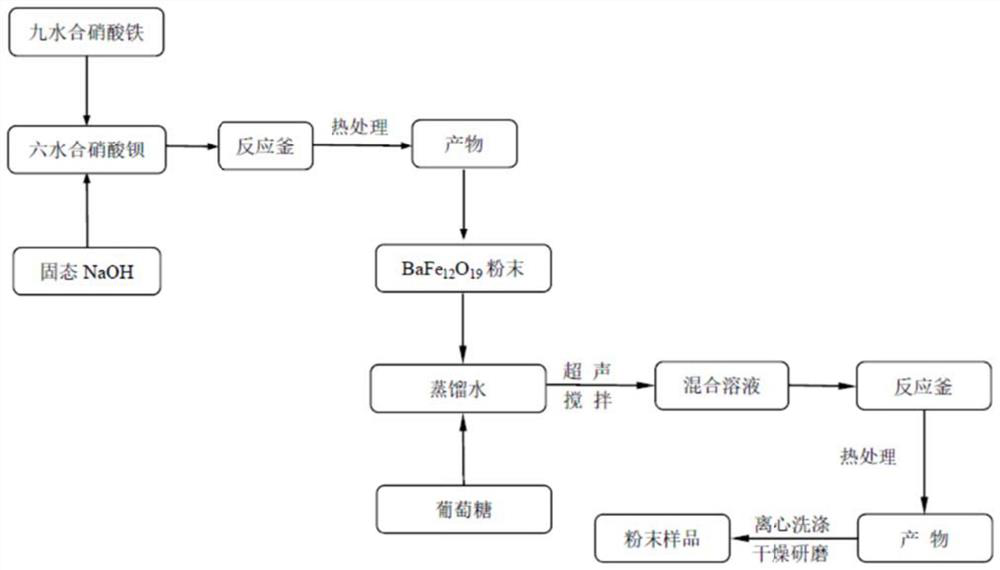

[0033] The steps of preparing barium ferrite carbon sphere nanocomposite microwave absorbing material are as follows:

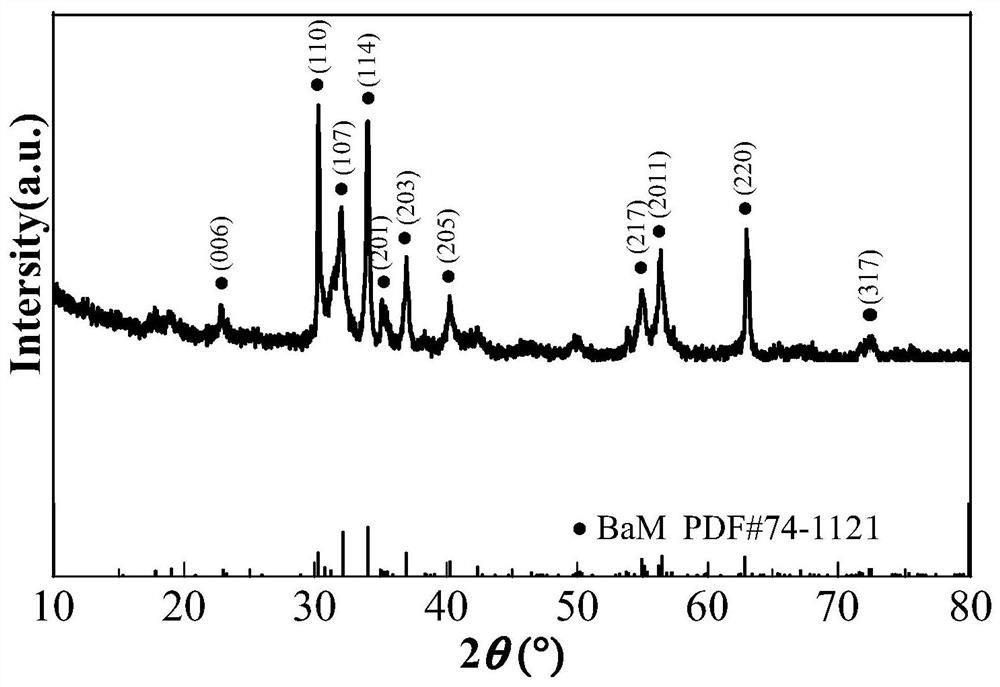

[0034] (1) Barium ferrite single-phase preparation

[0035] Single-phase barium ferrite nano-magnetic powder is first prepared by hydrothermal method: according to n(Ba 2+ ):n(Fe 3+ )=1:10 respectively weigh 1.6160g Fe(NO 3 ) 3 9H 2 O and 0.2306g Ba(NO 3 ) 2 ·6H 2 The solid powder of O was dissolved in a beaker with 35mL of distilled water, and ultrasonically oscillated to fully dissolve it; then transferred to a magnetic stirrer for full stirring; according to the atomic ratio n(OH - ) / n(NO 3- )=3 Weigh 1.56g sodium hydroxide solid powder, and dissolve in 35mL distilled water; And add it dropwise in the above-mentioned barium-iron solution, adjust the pH value of the mixed solution to 11; Fully adjust the mixed solution After stirring, put it into a metal reaction kettle, place the reaction kettle in an electronic oven, set the temperature at 220°C,...

Embodiment 2

[0042] (1) Barium ferrite single-phase preparation

[0043] The single-phase barium ferrite nano-magnetic powder is first prepared by hydrothermal method: n(Ba 2+ ):n(Fe 3+ )=1:8 respectively weigh 1.6160g Fe(NO 3 ) 3 9H 2 O and 0.1845g Ba(NO 3 ) 2 ·6H 2 The solid powder of O was dissolved in a beaker with 25mL of distilled water, and ultrasonically oscillated to fully dissolve it; then transferred to a magnetic stirrer for full stirring; according to the atomic ratio n(OH - ) / n(NO 3- )=3 weigh 1.56g sodium hydroxide solid powder, and dissolve it in 50mL distilled water; and add it dropwise in the above-mentioned barium iron solution, adjust the pH value of the mixed solution to 9; adjust the mixed solution After fully stirring, put it into a metal reaction kettle, place the reaction kettle in an electronic oven, set the temperature at 180°C, and set the time for 8 hours; Wash three times, and the speed of the high-speed centrifuge during washing is set to 12000r / min....

Embodiment 3

[0049] (1) Barium ferrite single-phase preparation

[0050] The single-phase barium ferrite nano-magnetic powder is first prepared by hydrothermal method: n(Ba 2+ ):n(Fe 3+ )=1:12 Weigh respectively 1.6160g Fe(NO 3 ) 3 9H 2 O and 0.2768g Ba(NO 3 ) 2 ·6H 2 The solid powder of O was dissolved in a beaker with 50 mL of distilled water, and ultrasonically oscillated to fully dissolve it; then transferred to a magnetic stirrer for full stirring; according to the atomic ratio n(OH - ) / n(NO 3- )=3 Weigh 1.56g sodium hydroxide solid powder, and dissolve in 25mL distilled water; And add it dropwise in the above-mentioned barium-iron solution, adjust the pH value of the mixed solution to 12; Fully adjust the mixed solution After stirring, put it into a metal reaction kettle, place the reaction kettle in an electronic oven, set the temperature at 230°C, and set the time for 4 hours; after the reaction is completed, clean the formed precipitate with 8% dilute hydrochloric acid, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com