Gel-free needle punching absorption core and sanitary accessories containing core

An absorbent core and acupuncture technology, applied in the field of personal hygiene products, can solve the problems of inability to fix fluff pulp and SAP, low production speed of equipment, no layering and no partitioning, etc., to reduce skin irritation and toxic and harmful substances Release, reduce the natural decomposition cycle, and reduce the effect of using ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

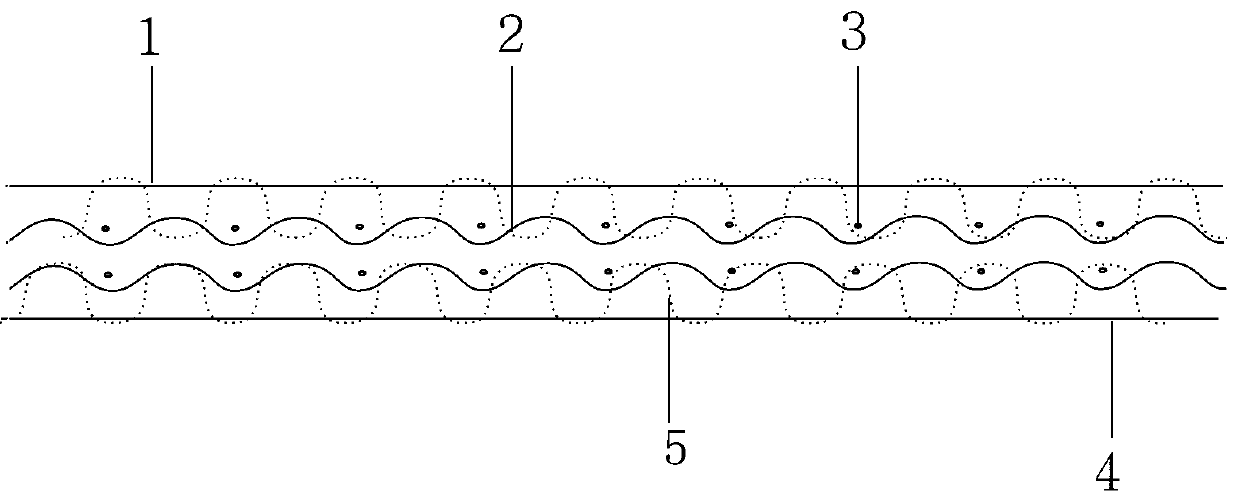

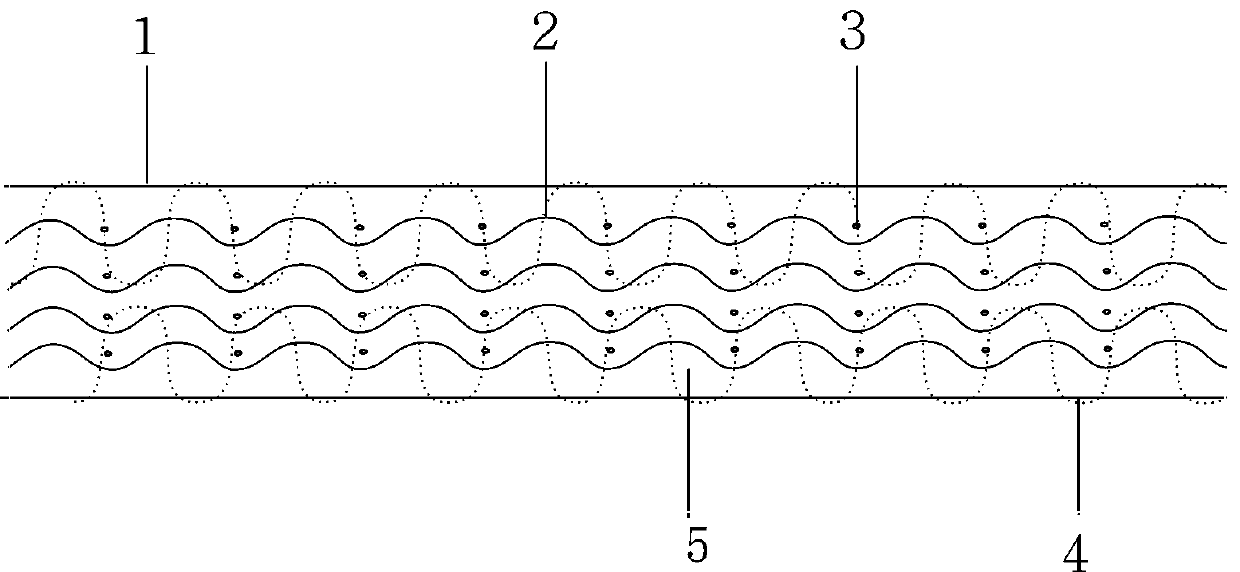

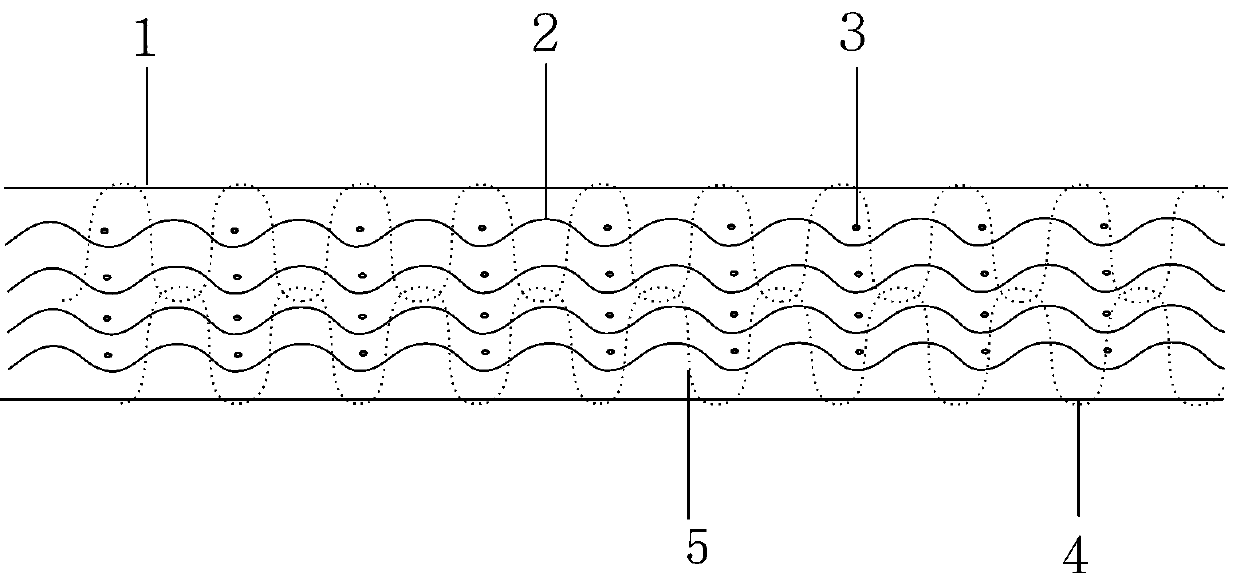

[0038] A glue-free needle-punched absorbent core, characterized in that the core comprises a surface layer of non-woven fabric, an intermediate layer and a bottom layer of non-woven fabric, the intermediate layer comprises at least one layer of cotton fiber, at least one layer of high In the water-absorbing resin particle layer, the core body is formed through at least one needling process.

[0039] A cotton fiber layer and a superabsorbent resin particle layer of the middle layer are formed by needle punching with the surface layer or the bottom non-woven fabric.

[0040] One layer of cotton fiber layer of the middle layer and the non-woven fabric of the surface layer or the bottom layer are formed by needling.

[0041] The needled top layer and bottom layer are connected through the cotton fiber layer.

[0042] The formation is formed by at least one needle-punching process, including laying a cotton fiber layer on the bottom non-woven fabric and sprinkling high water-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com