Battery cell pole sheet and battery cell

A pole piece and battery cell technology, which is applied in the field of battery production, can solve the problem of over-thickness of the pole piece glue, achieve the effect of improving safety, increasing volume energy density, and avoiding the safety risk of lithium analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

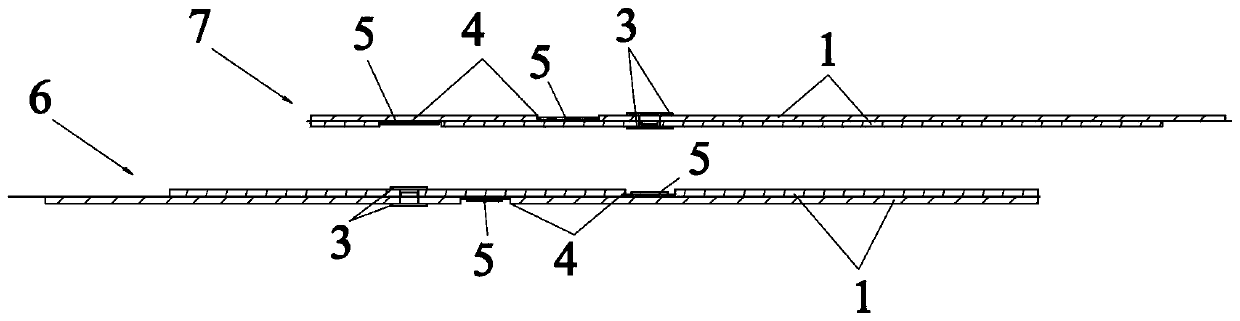

[0028] Such as Figure 1~4 As shown, a battery pole piece includes a pole piece and a pole piece. The pole piece is provided with a coating area 1 and an empty foil area 2. The pole piece is accommodated in the empty foil area 2. The pole piece is covered with a first insulating glue 3 The coating area 1 is provided with several grooves 4 at intervals to cooperate with the first insulating glue 3 , the first insulating glue 3 is accommodated in the grooves 4 , and the bottom surface of the grooves 4 is provided with a second insulating glue 5 . In the manufacturing process of the existing lithium-ion batteries, in order to avoid the problem of lithium precipitation during the charging process of the positive and negative electrodes and reduce the potential safety hazard, an auxiliary adhesive tape will be pasted on the positive and negative electrodes themselves to prevent the insertion of lithium ions. At the same time, in order to protect the thinner area of the coating, t...

Embodiment 2

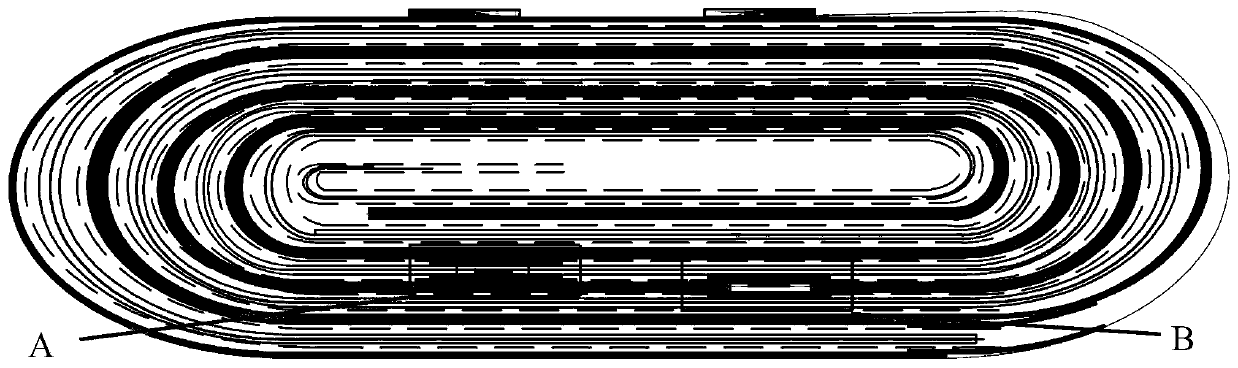

[0039] Such as Figure 1~4 Shown, a kind of electric core, comprises separator and the anode sheet 6 and cathode sheet 7 that are made of above-mentioned electric core pole sheet, anode sheet 6, cathode sheet 7 pole separators are wound to form electric core, the anode sheet 6 The empty foil area 2 and the empty foil area 2 of the cathode sheet 7 are staggered, the empty foil area 2 of the anode sheet 6 is welded with a negative electrode ear 8, the empty foil area 2 of the cathode sheet 7 is welded with a positive electrode ear 9, and the anode sheet 6 corresponds to the positive electrode ear 9 is provided with a groove 4, and the position of the cathode sheet 7 corresponding to the negative tab 8 is provided with a groove 4.

[0040] It should be noted that: the empty foil area 2 of the anode sheet 6 and the empty foil area 2 of the cathode sheet 7 are staggered to prevent the negative tab 8 and the positive tab 9 from overlapping together, and prevent the short circuit bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com