High-integrated double-axis bearing unit

A dual-axis, high-integration technology, used in shafts and bearings, bearings, rolling contact bearings, etc., can solve problems such as bloated and complicated structures, and achieve the effect of simplifying the bearing structure and ensuring functional operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the structure and function of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

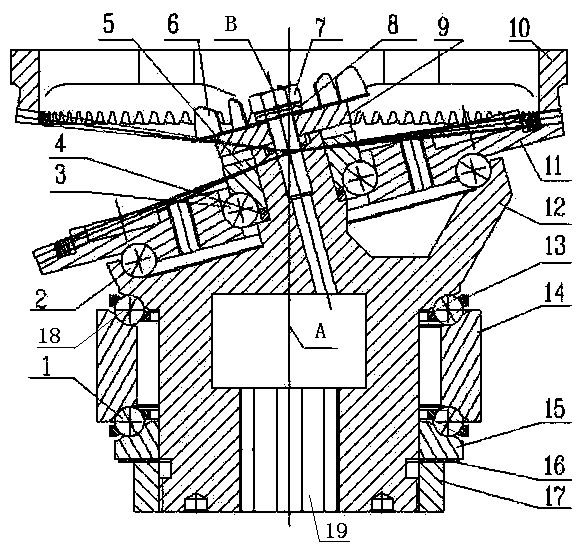

[0018] See attached figure 1 , a highly integrated double-axis bearing unit, the double-axis bearing includes a first inner ring 12, an outer ring 14, a rotating steel ball, a cage 13, a second inner ring 5, a swinging steel ball and an engaging ring gear 11; The first inner ring 12 is composed of a lower part, an upper part and a supporting part from bottom to top, and a cage 13 is installed between the outer ring 14 and the lower part of the first inner ring, and the cage 13 keeps the rotating steel balls between the outer ring and the first inner ring. Between the lower part of the first inner ring, the first bearing structure is formed, and the axis of this part is the first axis A; the second inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com