Integrated wire control mechanism and assembly method thereof

An integrated, wire-controlled technology, used in bicycle accessories, bicycle brakes, etc., can solve the problems of reducing work efficiency, increasing manpower and time, and complex assembly steps, achieving the effect of convenient assembly and saving manpower and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

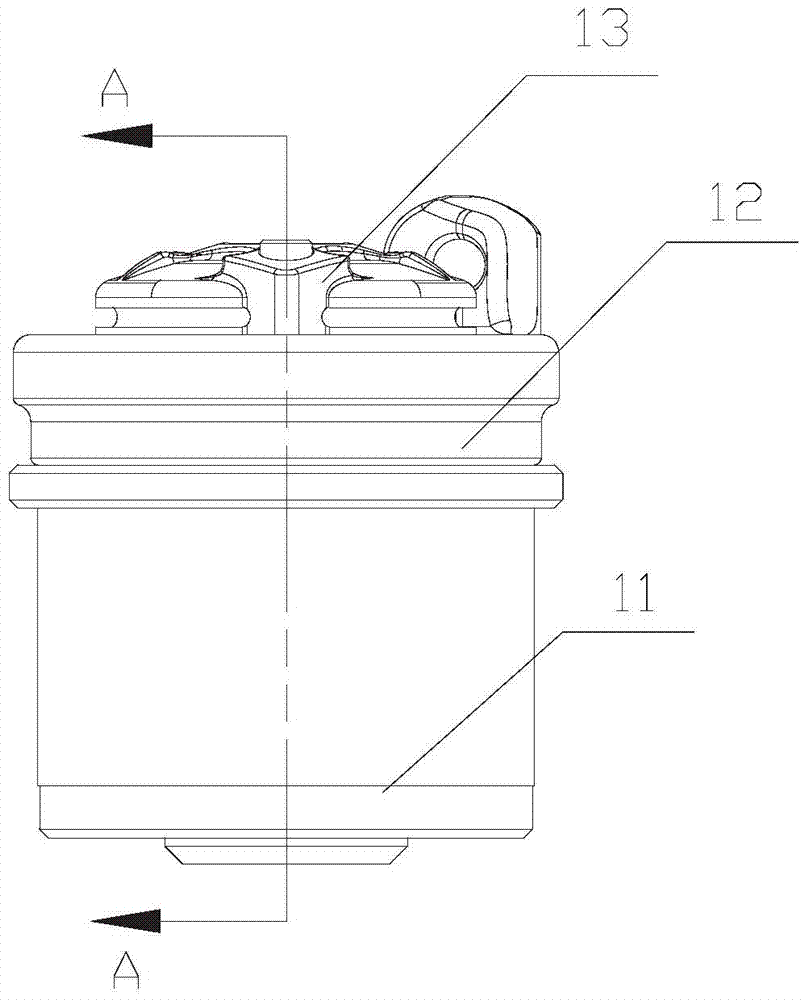

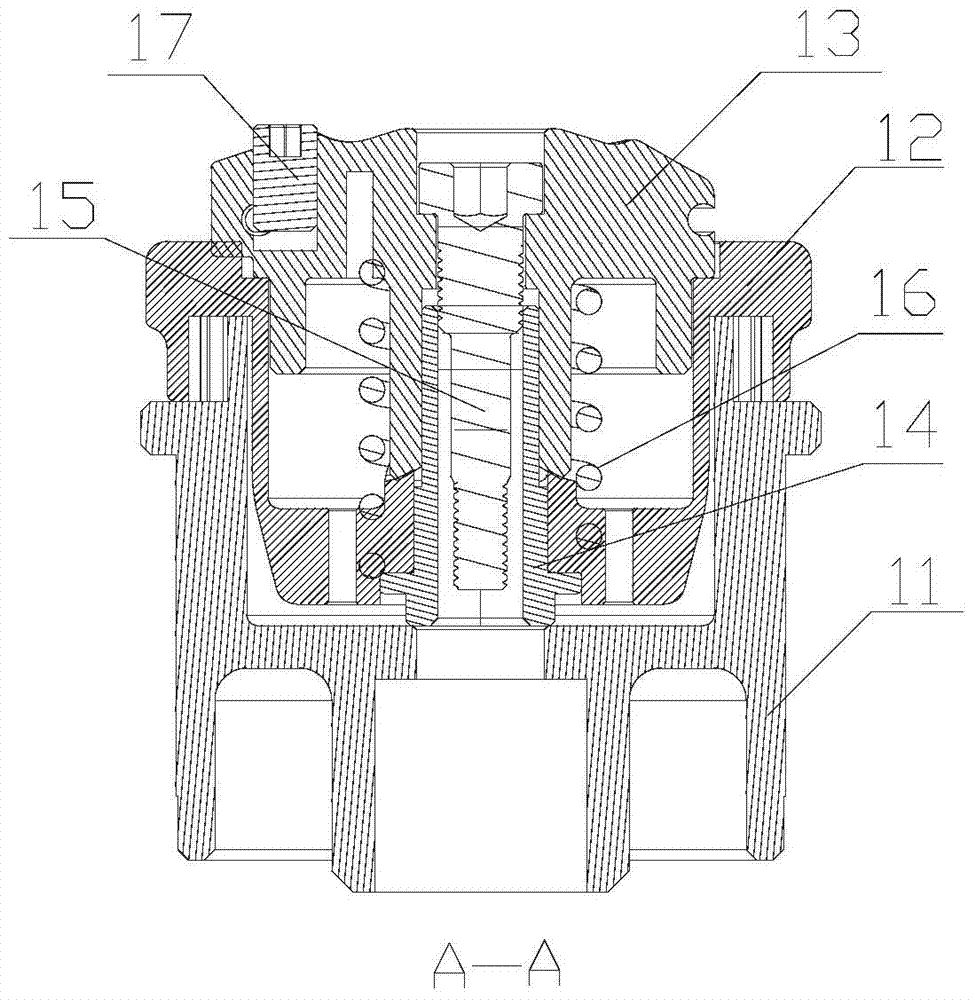

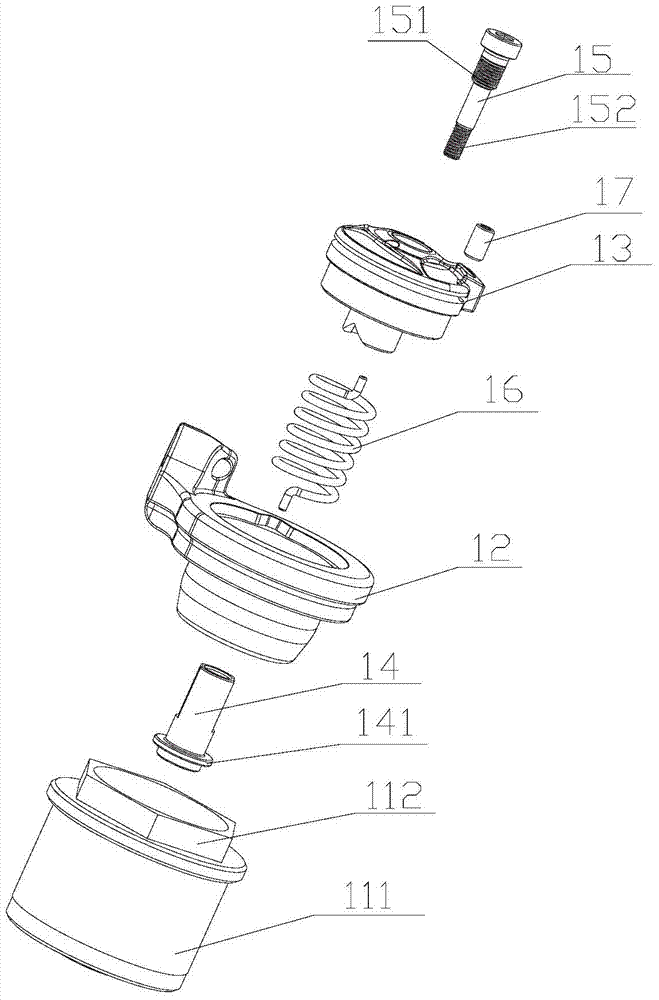

[0032] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

[0033] see Figure 1-3 As shown, the present invention provides an integrated wire control mechanism for connecting the brake inner cable and the front fork. The front fork is provided with an oil pressure lock rod (not shown in the figure), and the oil pressure lock rod is provided with an internal thread structure, the wire control mechanism includes a fixed seat 11, a buckle 12, a locking knob 13, a connecting rotor 14, positive and negative screws 15 and a torsion spring 16;

[0034] The connecting rotor 14 is inserted into the bottom end of the locking knob 13, the torsion spring 16 is sleeved on the bottom end of the locking knob 13, and the three are set together in the buckle 12, and the buckle 12 is inserted into the fixing seat 11 Among them, the positive and negative tooth screw 15 includes a body, a nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com