Pasting equipment for hardware composite product

A composite product and hardware technology, applied in the field of assembly equipment, can solve problems such as unfavorable assembly and low work efficiency, and achieve the effects of convenient adjustment, guaranteed bearing stress, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

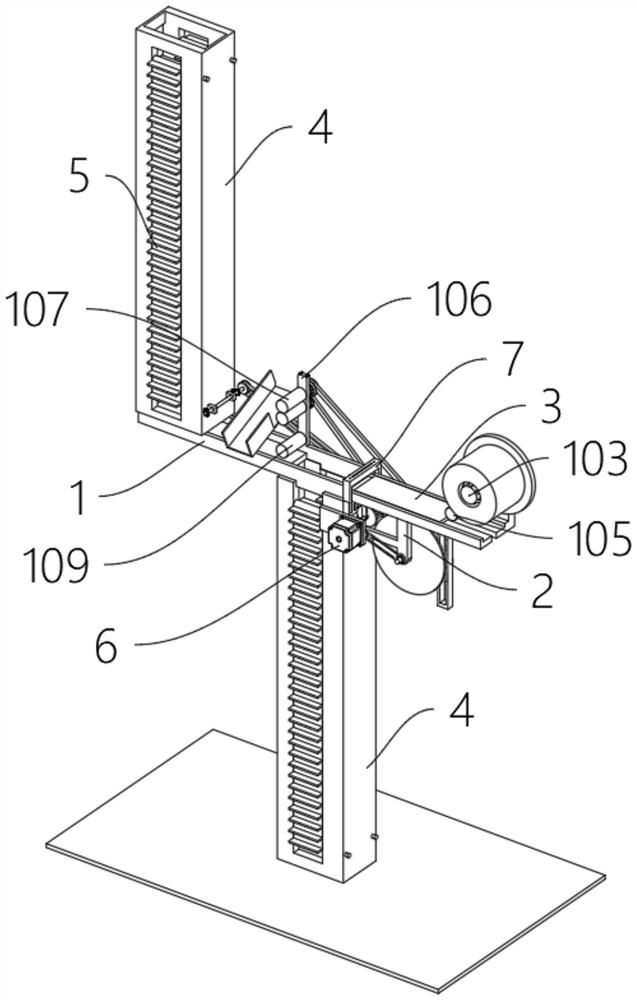

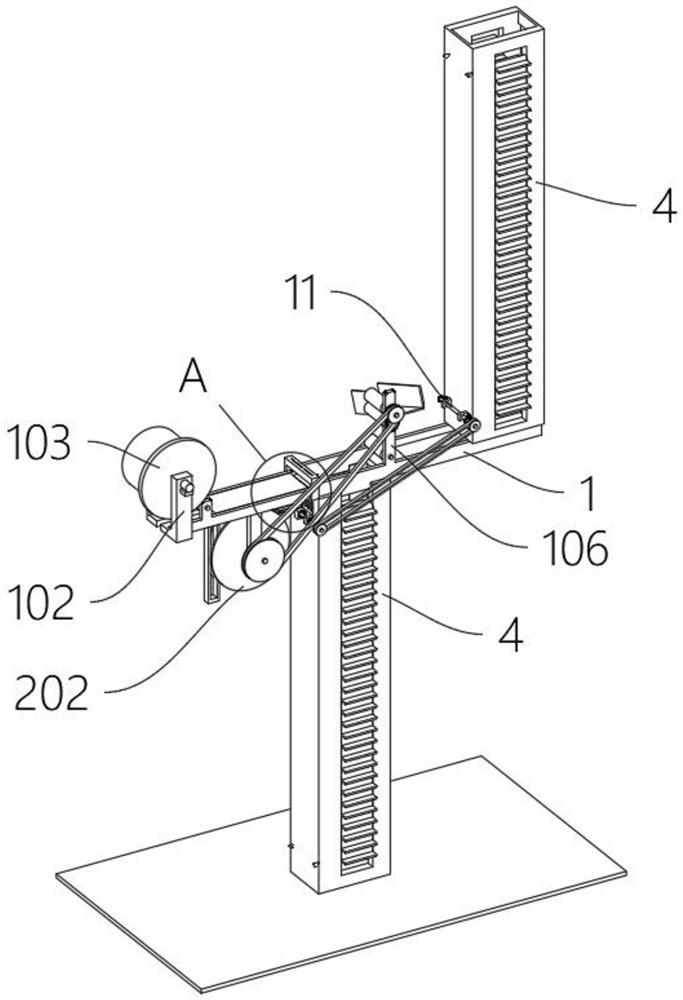

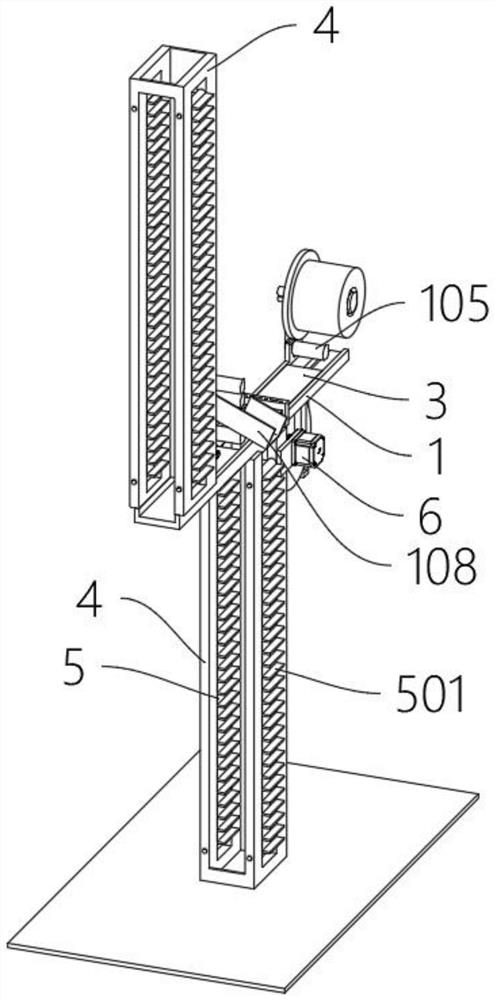

[0036] Example: please refer to Figure 1 to Figure 10 :

[0037] The present invention proposes a bonding device for metal composite products, comprising: an intermediate sliding channel 1, the main body of the intermediate sliding channel 1 is a channel structure, the middle sliding channel 1 is provided with a sheet feeding hole 101, and the back of the sheet feeding hole 101 is opened. A through groove is formed through the middle sliding channel 1 in the middle of the side; the T-shaped transmission frame 2, the number of the T-shaped transmission frame 2 is set to two groups, and the two groups of T-shaped transmission frames 2 are fixedly arranged under the rear side of the middle sliding channel 1; The plate 3, the push plate 3 is slidably arranged on the middle rear side of the intermediate sliding channel 1; the guiding square cylinder 4, the number of guiding square cylinders 4 is set to two groups, which are respectively fixed above the top of the intermediate slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com