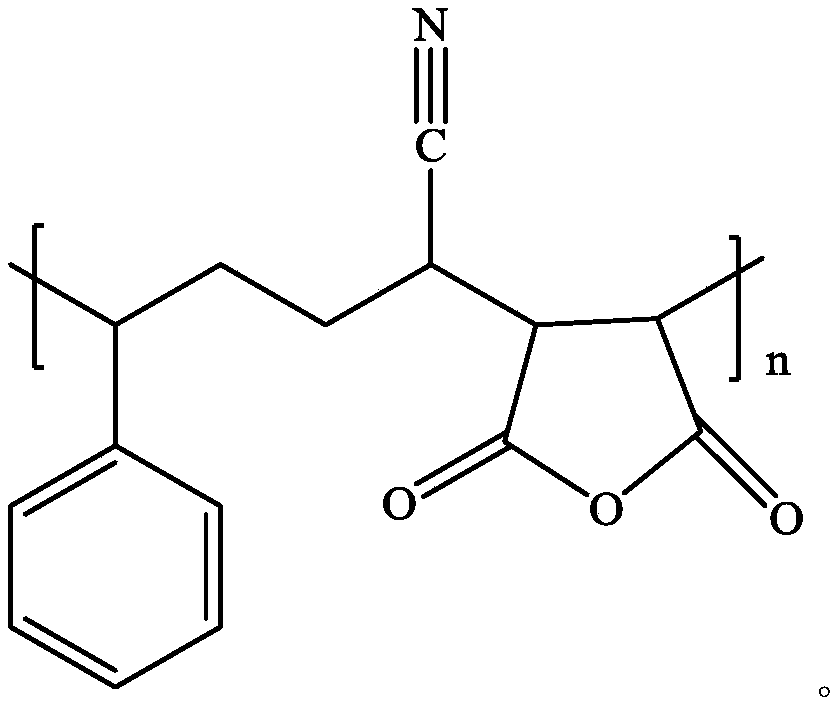

Needle-shaped control agent as well as preparation method and application thereof

A control agent and needle-shaped technology, which is applied in the field of supercapacitor electrode material preparation, can solve the problems of increasing resistance and difficult performance of active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

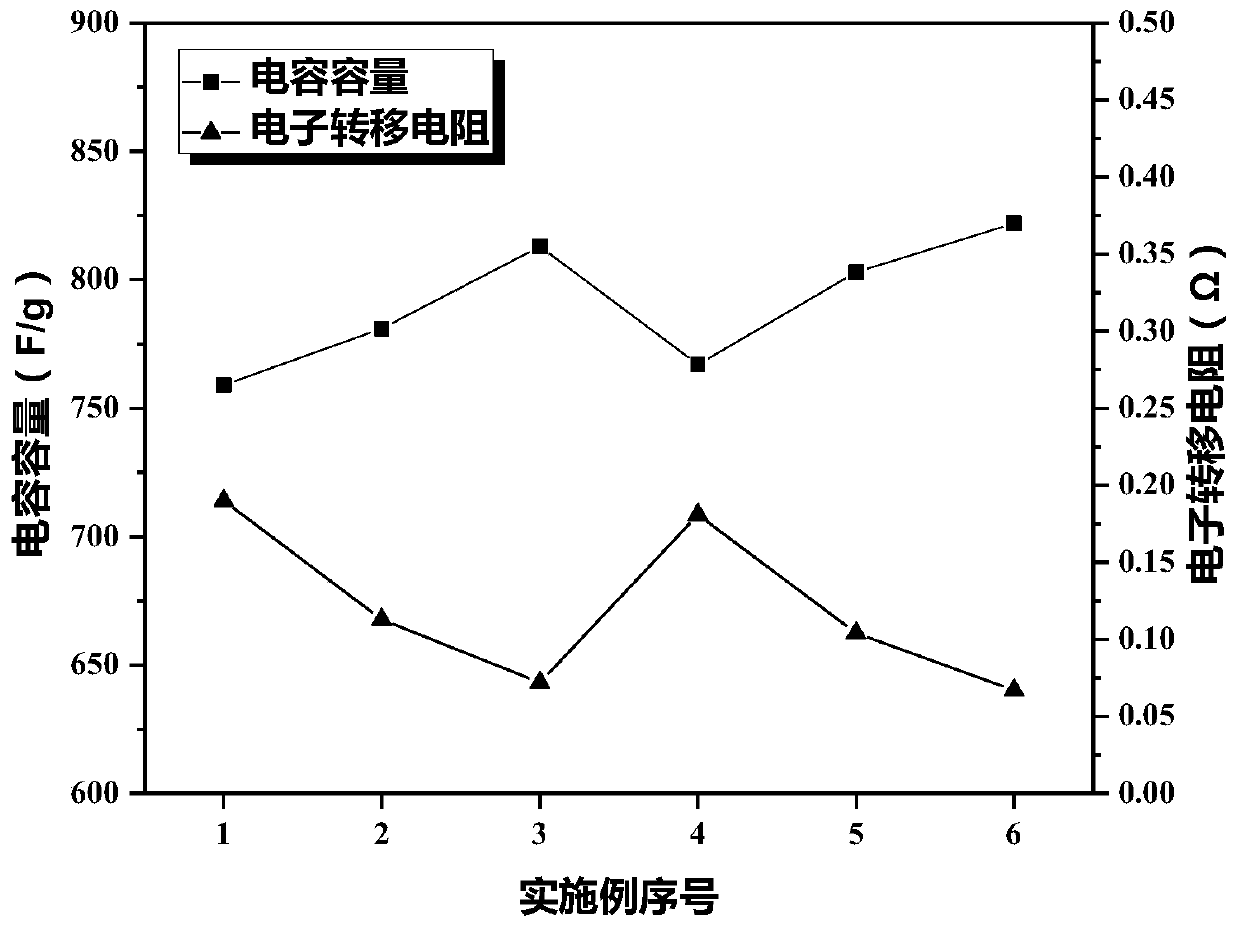

Embodiment 1

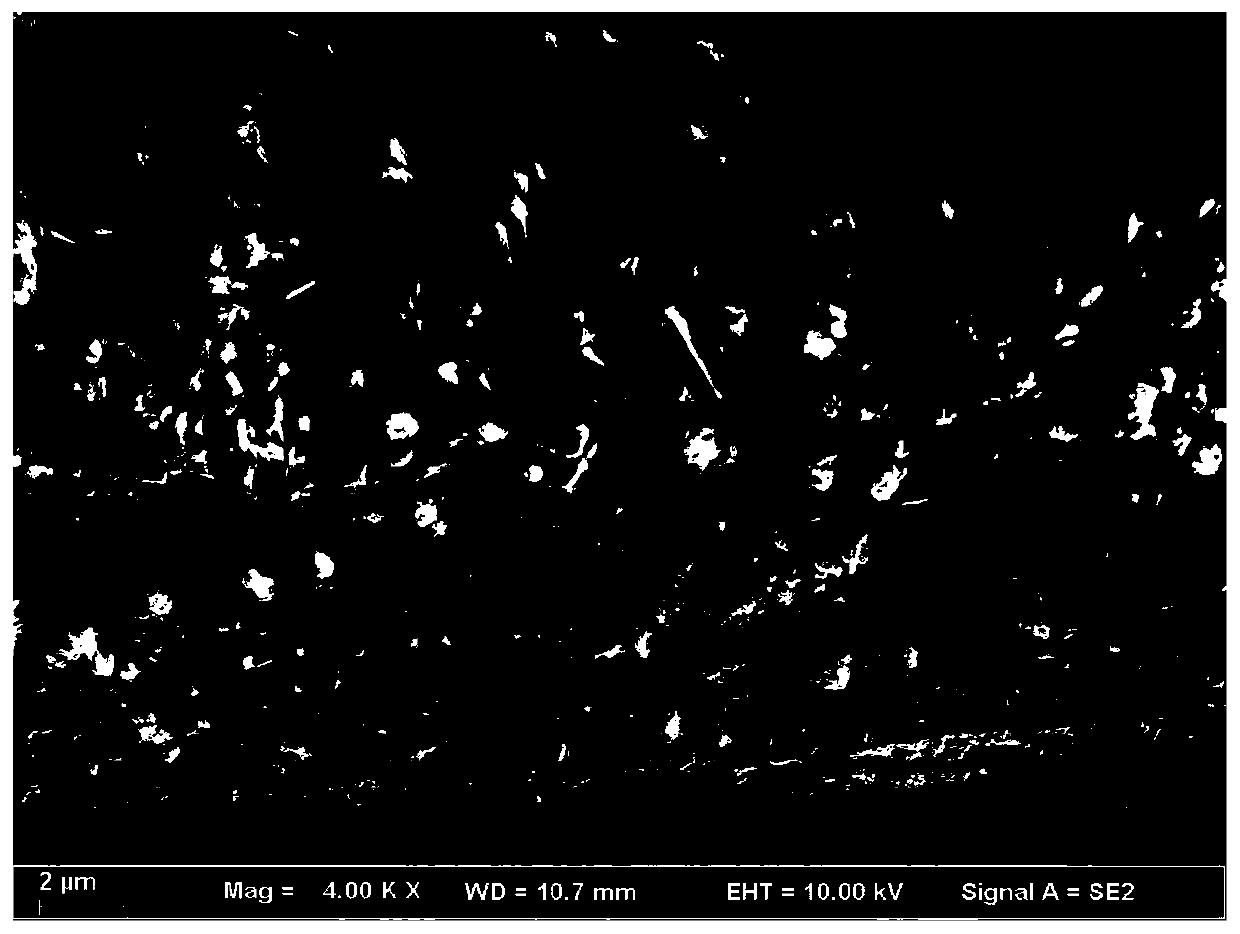

[0039] Embodiment 1 uses the preparation of the cobalt-nickel-based chalcogenide supercapacitor electrode plate of acicular control agent

[0040] The cobalt source and sulfur source used to prepare the active material are respectively: cobalt chloride and thiourea, and the molecular weight of the needle control agent is 400.

[0041] A method for preparing a supercapacitor electrode plate material containing a composition that can control the formation of needle-shaped cobalt-nickel-based chalcogenides, comprising the following steps:

[0042] (1) Cut a nickel foam plate (60% porosity) with a thickness of 0.5mm into a size of 5×5cm; soak it in acetone, 1M hydrochloric acid, 1M potassium hydroxide, absolute ethanol, deionized Ultrasonic cleaning in water for 10 minutes; then placed in a vacuum drying oven to raise the temperature to 80 ° C, and keep warm for 2 hours to obtain a clean nickel foam collector.

[0043] (2) Weighing the cobalt source, the sulfur source material an...

Embodiment 2

[0048] Embodiment 2 uses the preparation of the cobalt-nickel-based chalcogenide supercapacitor electrode plate of acicular control agent

[0049] The cobalt source and sulfur source used to prepare the active material are respectively: cobalt nitrate and thiourea, and the molecular weight of the needle control agent is 800.

[0050] A method for preparing a supercapacitor electrode plate material containing a composition that can control the formation of needle-shaped cobalt-nickel-based chalcogenides, comprising the following steps:

[0051] (1) Cut a nickel foam plate (65% porosity) with a thickness of 0.5mm into a size of 5×5cm; soak it in acetone, 1M hydrochloric acid, 1M potassium hydroxide, absolute ethanol, deionized Ultrasonic cleaning in water for 5 minutes, and then placed in a vacuum drying oven to raise the temperature to 70 ° C, and keep warm for 4 hours to obtain a clean nickel foam collector.

[0052] (2) taking cobalt source, sulfur source material and needle...

Embodiment 3

[0056] Embodiment 3 uses the preparation of the cobalt-nickel-based chalcogenide supercapacitor electrode plate of acicular control agent

[0057] The cobalt source and sulfur source used to prepare the active material are respectively: cobalt acetate and thiourea, and the molecular weight of the needle control agent is 500.

[0058] A method for preparing a supercapacitor electrode plate material containing a composition that can control the formation of needle-shaped cobalt-nickel-based chalcogenides, comprising the following steps:

[0059] (1) Cut a nickel foam plate (90% porosity) with a thickness of 0.5mm into a size of 5×5cm; soak it in acetone, 1M hydrochloric acid, 1M potassium hydroxide, absolute ethanol, deionized Ultrasonic cleaning in water for 5 minutes; then placed in a vacuum drying oven to raise the temperature to 75 ° C, and keep warm for 3 hours to obtain a clean nickel foam collector.

[0060] (2) taking cobalt source, sulfur source material and needle-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com