A carbon-carbon prefabricated body and preparation method thereof

A carbon-carbon preform and a technology for the preform, which are applied in the field of carbon-carbon preform and its preparation, can solve the problems of reducing the mechanical properties of the carbon-carbon preform, not releasing the tension force, and decreasing the mechanical properties of the carbon-carbon preform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

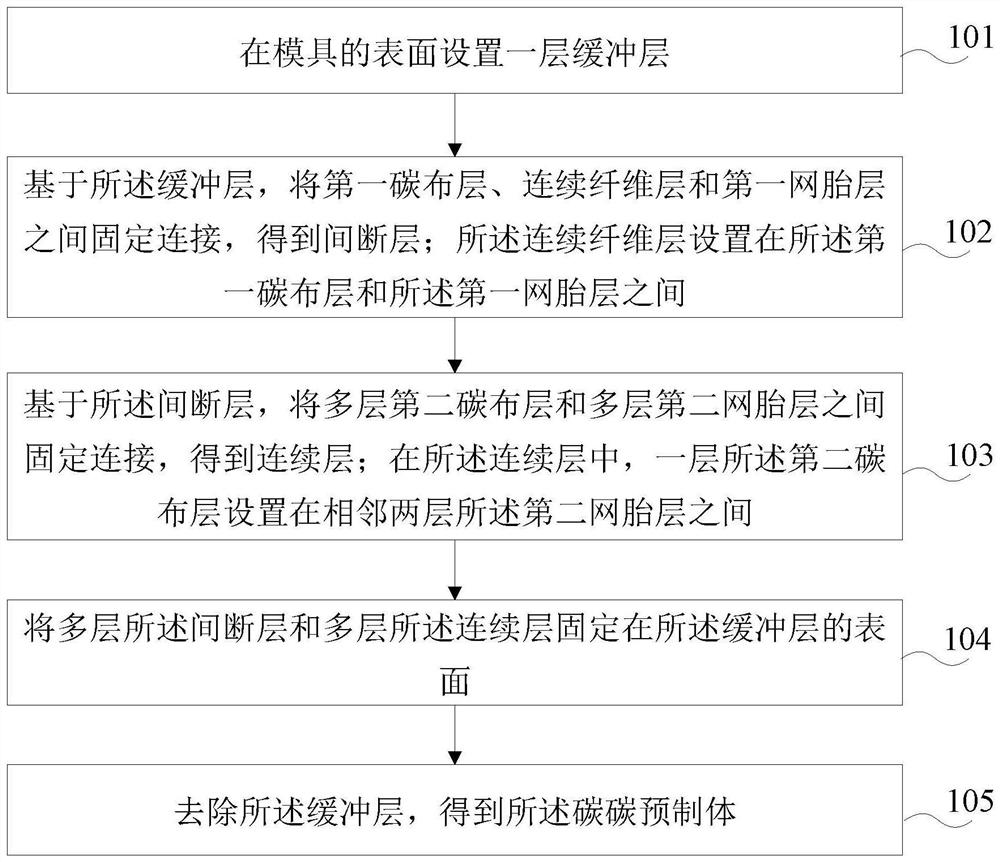

[0048] refer to figure 1 , figure 1 A flow chart of the steps of a method for preparing a carbon-carbon preform in Embodiment 1 of the present invention is shown. The method may include the steps of:

[0049] Step 101, setting a buffer layer on the surface of the mold.

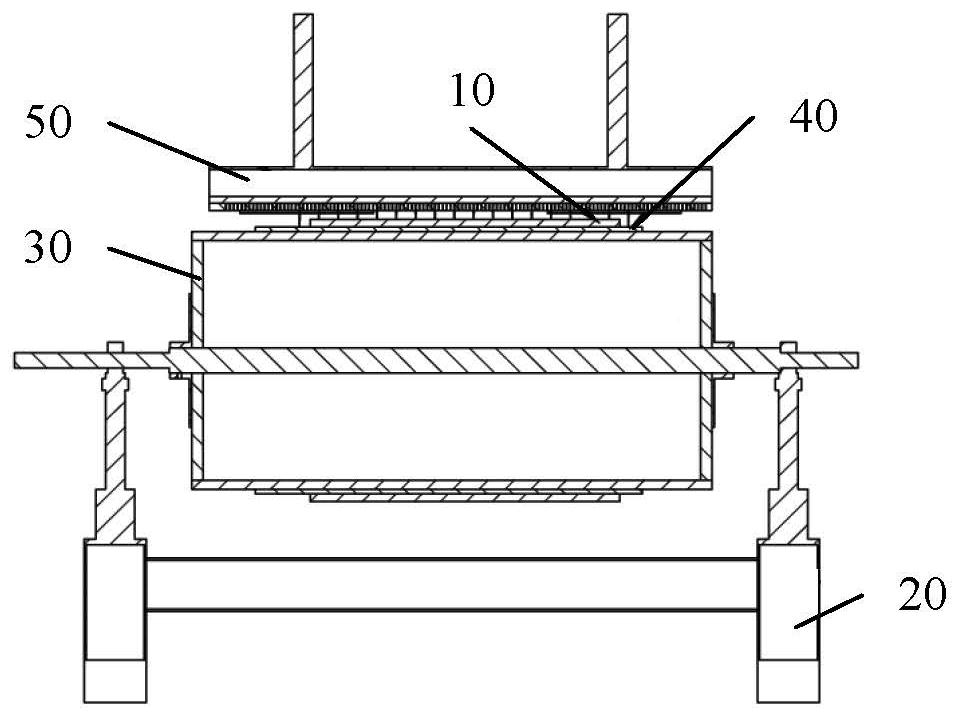

[0050] refer to figure 2 , which shows a schematic diagram of a carbon-carbon preform preparation device in Embodiment 1 of the present invention. When the carbon-carbon prefabricated body is prepared by the fiber acupuncture method, the mold 30 is installed on the acupuncture equipment workbench 20, a layer of buffer layer 40 is arranged on the surface of the mold 30, and multiple layers are laid on the buffer layer 40 to prepare the carbon-carbon prefabricated body. The raw material of the body 10 is needled by the needling mechanism 50 to obtain the carbon-carbon prefabricated body 10 .

[0051] Further, the buffer layer should meet the following conditions:

[0052] (1) The texture of the buffer layer...

Embodiment 2

[0094] see Image 6 , shows a flow chart of the steps of a method for preparing a carbon-carbon preform in Embodiment 2 of the present invention, and the method may include the following steps:

[0095] Step 201, setting a buffer layer on the surface of the mold.

[0096] For this step, reference may be made to the above-mentioned step 101 for details, which will not be repeated here.

[0097] Step 202, disposing the first carbon cloth layer on the buffer layer.

[0098] In this step, the first carbon cloth is cut according to the size of the model, and the cut first carbon cloth is wrapped on the buffer layer on the surface of the mold with a certain tension to obtain the first carbon cloth layer.

[0099] Optionally, if the surface of the carbon-carbon prefabricated product includes an arc structure, the surface of the mold corresponding to the carbon-carbon prefabricated product will also include an arc structure. At this time, in order to ensure that the first carbon clo...

Embodiment 3

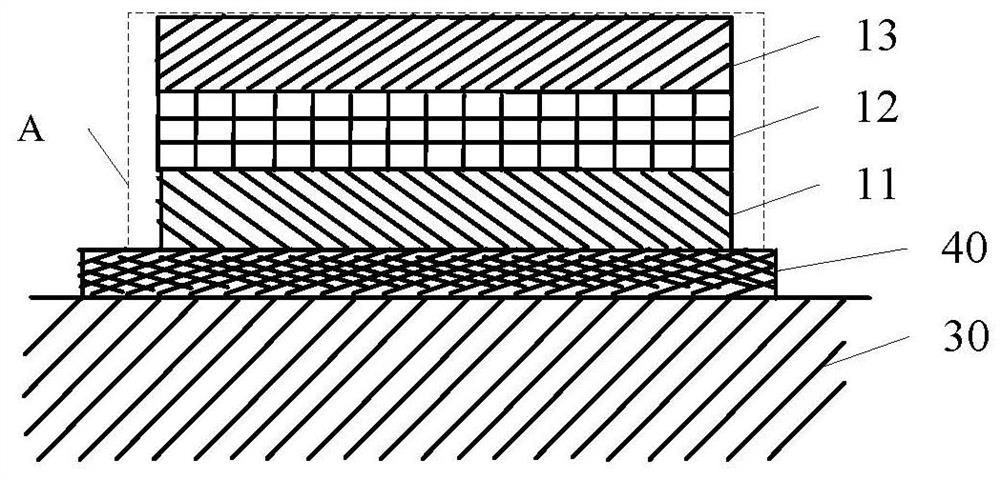

[0154] refer to Figure 5 , which shows a structural diagram of a carbon-carbon prefabricated body in Embodiment 3 of the present invention, which may specifically include:

[0155] A multi-layer discontinuous layer A and a multi-layer continuous layer B; the discontinuous layer A and the continuous layer B are sequentially arranged at intervals, and one continuous layer B is arranged between two adjacent discontinuous layers A; the discontinuous layer A1 includes a first carbon cloth layer 11 , continuous fiber layer 12 and the first net tire layer 13, continuous fiber layer 12 is arranged between the first carbon cloth layer 11 and the first net tire layer 13; continuous layer B1 includes multi-layer second carbon cloth layer 14 and multi-layer The second net tire layer 15, one deck of the second carbon cloth layer 14 is arranged between the second net tire layer 15 of two adjacent layers; Wherein, the first net tire layer 11 in the intermittent layer A1 is arranged on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com