Preparation method and application of inonotus obliquus extract granules

A technology of Inonotus obliquus and granules, applied in the field of Inonotus obliquus extracts, can solve problems such as insufficient research reports, achieve high content of Inonotus obliquus polysaccharides, be convenient to carry and transport, and be conducive to popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

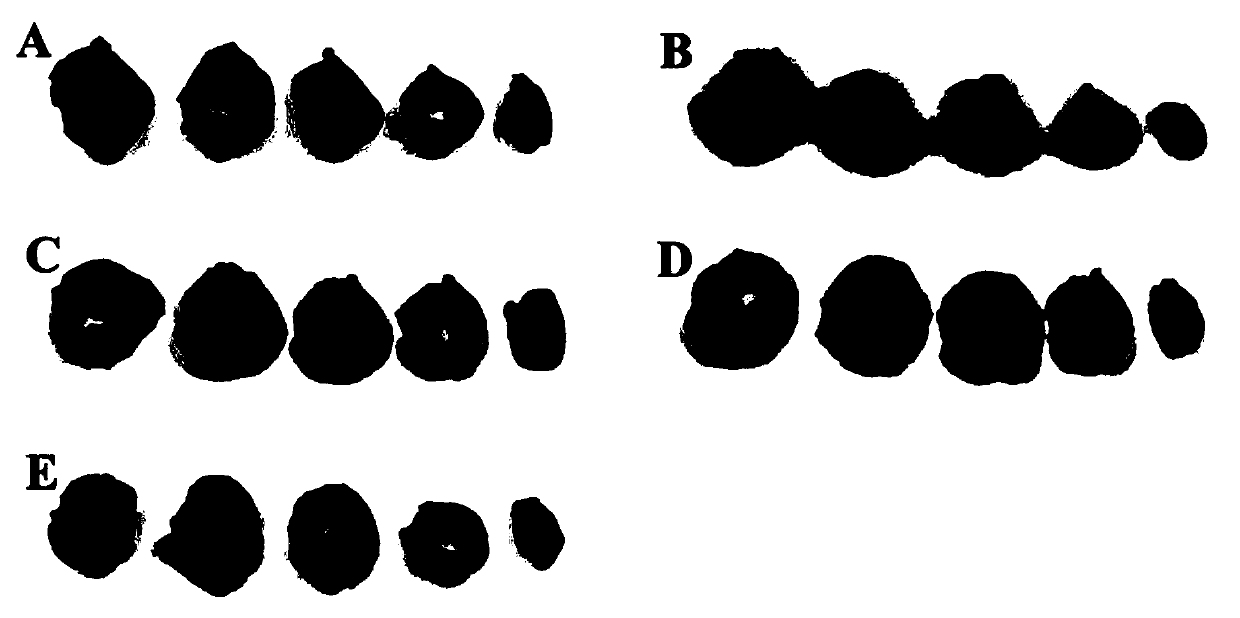

[0025] Embodiment 1: the preparation method of Inonotus obliquus extract

[0026] Precisely weigh 100g of Inonotus obliquus medicinal material, pulverize it, pass through a 40-mesh sieve, add 1000mL of water, take a water bath at 80°C, extract for 2 hours, collect the supernatant after filtering through 3 layers of gauze, repeat twice, and finally combine the obtained supernatant, Vacuum and dry under reduced pressure to obtain the extract of Inonotus obliquus. The polysaccharide content is 2.83%.

example 2

[0027] Example 2: the preparation method of Inonotus obliquus extract

[0028] Precisely weigh 100g of Inonotus obliquus medicinal material, crush it, pass through a 60-mesh sieve, add 800mL of 20% ethanol, bathe in 80°C water, extract for 2 hours, collect the supernatant after filtering through 3 layers of gauze, repeat twice, and finally combine the obtained supernatants liquid, dried under reduced pressure in vacuo to obtain Inonotus obliquus extract. The polysaccharide content is 2.48%.

example 3

[0029] Example 3: The preparation method of Inonotus obliquus extract

[0030] Precisely weigh 100g of Inonotus obliquus medicinal material, pulverize it, add 1200mL of 50% ethanol, take a water bath at 80°C, extract for 2 hours, collect the supernatant after filtering through 3 layers of gauze, repeat twice, finally combine the obtained supernatant, and vacuum decompress Dried to obtain the Inonotus obliquus extract. The polysaccharide content is 2.08%.

[0031] Adopt low-temperature microwave vacuum drying equipment in the present invention, its advantage is the following points: 1. Conventional vacuum drying equipment all adopts steam to heat, needs to heat from inside to outside, and heating rate is slow and needs to expend a large amount of coal, and microwave vacuum The drying equipment adopts electromagnetic wave heating, without heat transfer medium, directly heating to the inside of the object, with fast heating speed, high efficiency, greatly shortened drying cycle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com