Ball sealing structure and hydraulic valve

A sealing structure and hydraulic valve technology, applied in the valve shell structure, fluid pressure actuation device, valve details, etc., can solve the problems of sealing failure, high pressure oil leakage, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be described in detail and completely through specific embodiments in conjunction with the accompanying drawings.

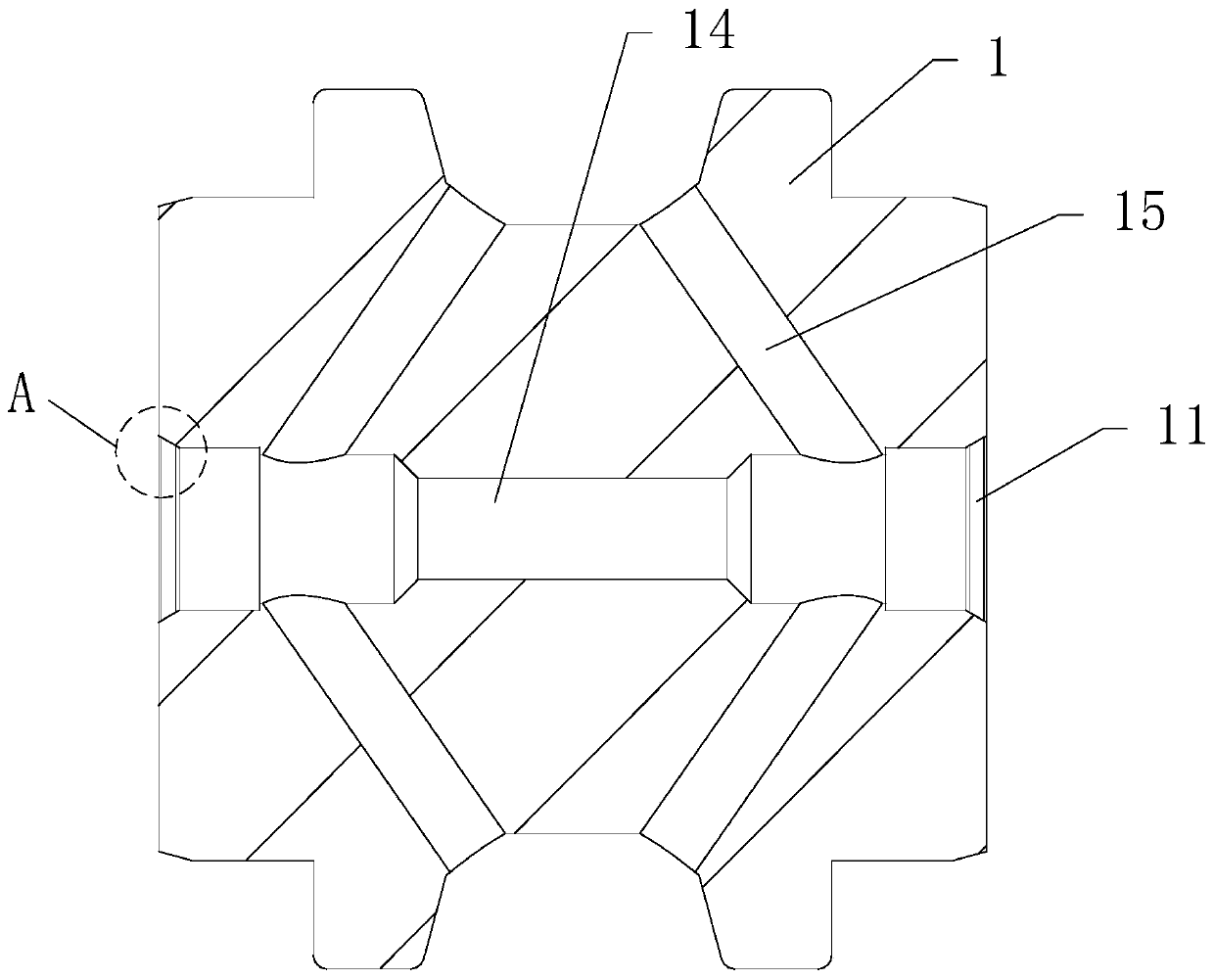

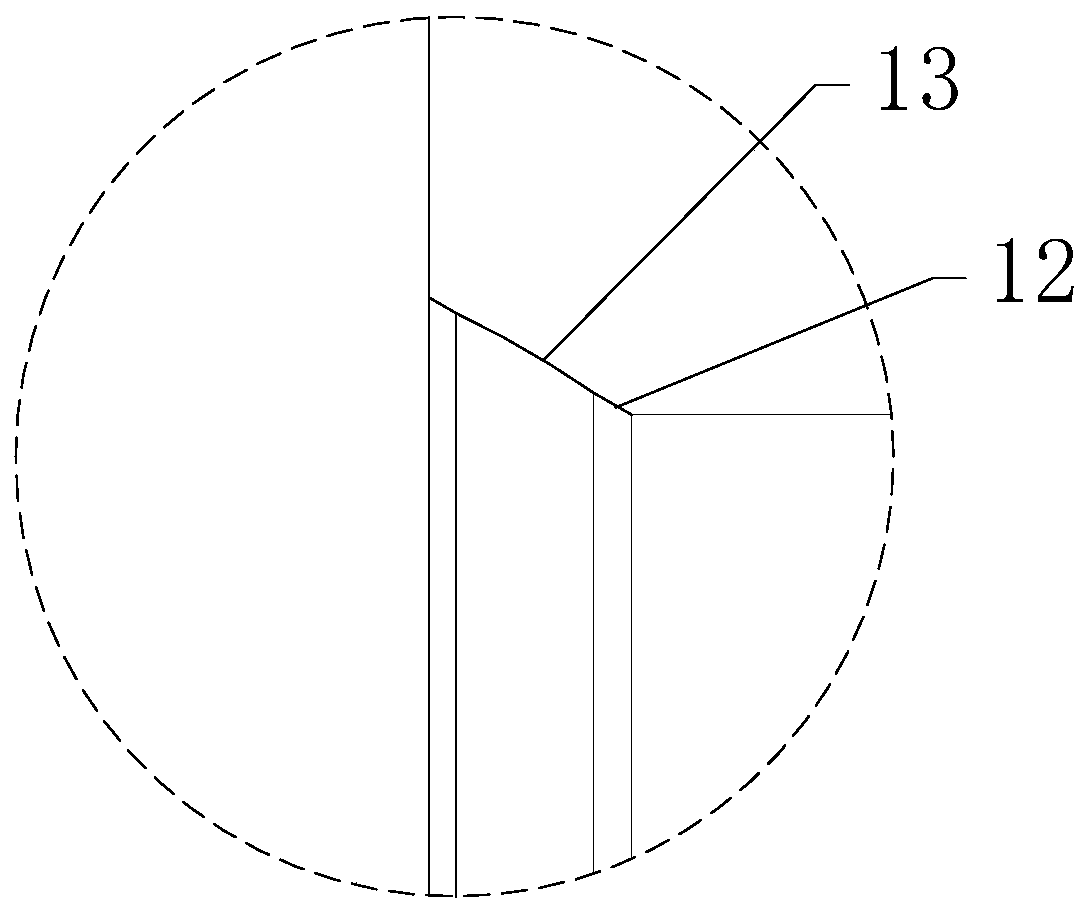

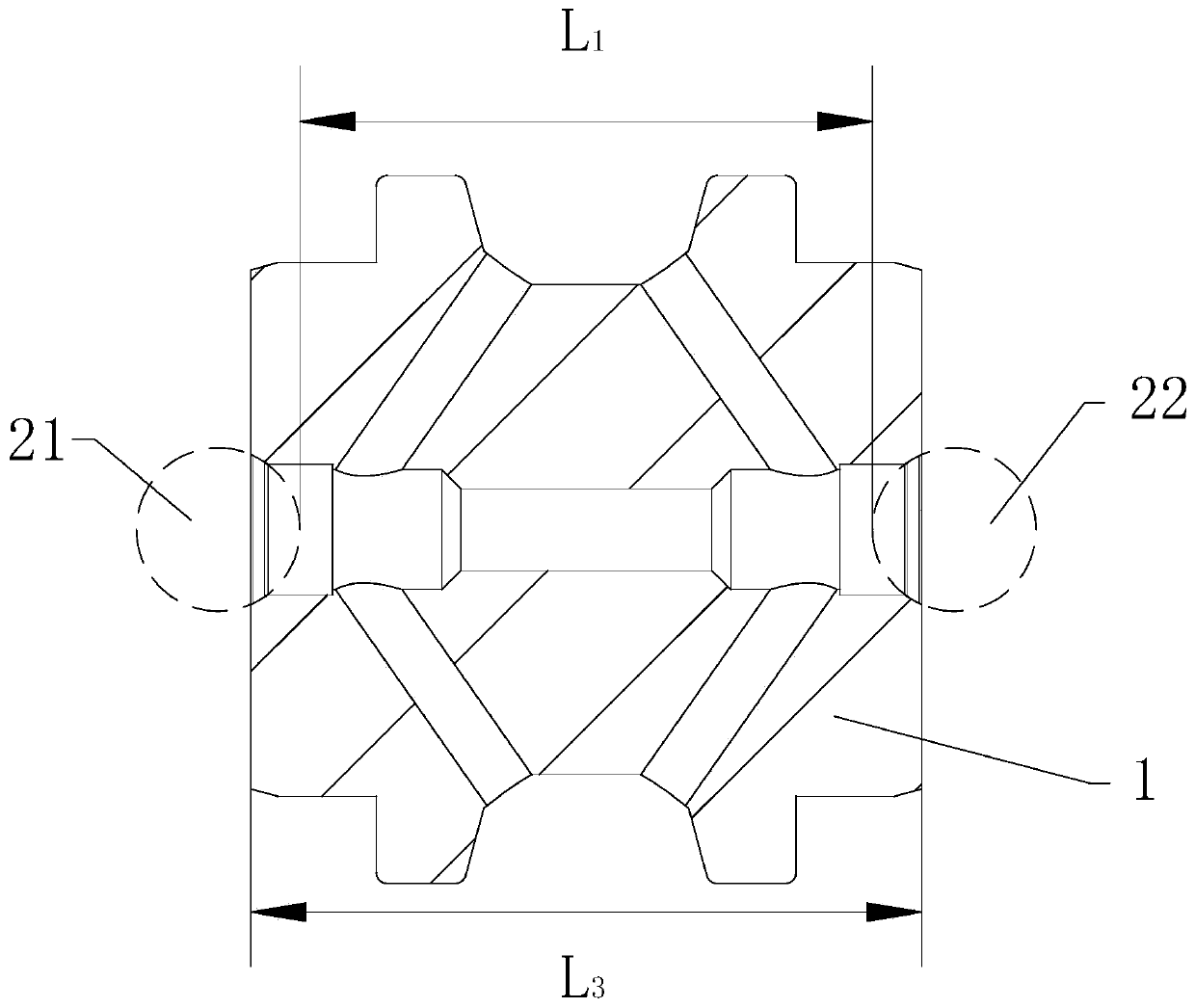

[0025] Please refer to Figure 1-5 As shown, the present invention provides a ball sealing structure, including a ball and a first valve core 1, the surface of the first valve core 1 is provided with a valve port 11, the diameter of the inner hole of the valve port 11 is smaller than the diameter of the ball, and the valve port 11 is provided with There is a conical sealing surface 12, and the conical sealing surface 12 is provided with an arc sealing surface 13 that is consistent with the arc surface of the sphere, and the arc sealing surface 13 is not easy to produce a breach, and the sphere is against the arc sealing surface 13 to form a sealed structure. When the ball seals the valve port 11, the ball can abut against the arc sealing surface 13 to form a surface seal. The way of setting the arc sealing sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com