Functional layer coating of projection curtain, the projection curtain and manufacturing method

A technology of projection screen and functional layer, applied in the field of projection, can solve the problems of general picture effect, low brightness gain, narrow viewing angle, etc., and achieve the effect of improving corrosion resistance and wrinkle resistance, improving brightness and contrast, and protecting from damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

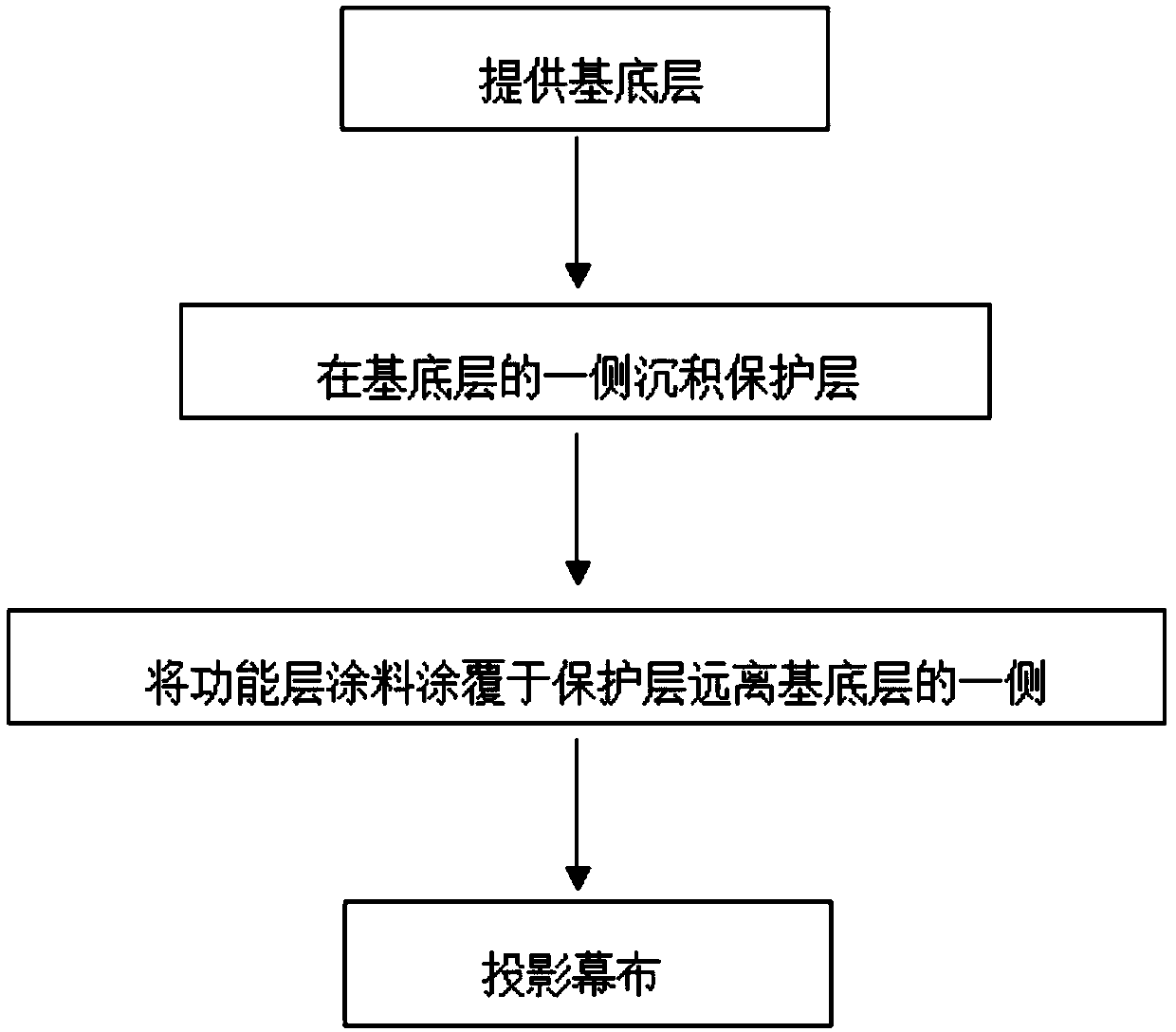

[0041] A method for making a projection screen, comprising the following steps:

[0042] (1) Provide a base layer, the material of the base layer is PET, and the thickness of the base layer is 0.8mm;

[0043] (2) Deposit a protective layer on one side of the base layer, the protective layer is a transparent silicone grease layer, and its thickness is 0.8mm;

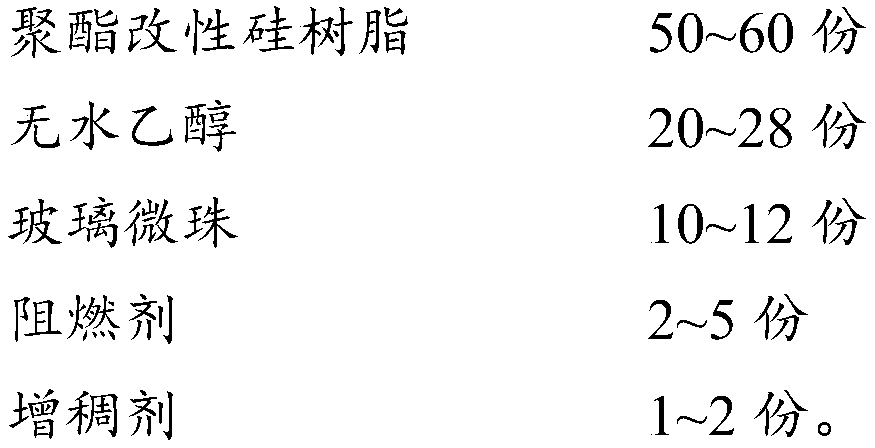

[0044] (3) Mix and stir 50 parts of polyester-modified silicone resin and 28 parts of absolute ethanol, raise the temperature to 50-60°C and keep for 10 minutes, then add 10 parts of glass microspheres, 2 parts of flame retardant, and 1 part of thickener, Put it into a disperser and disperse ultrasonically at a speed of 500 rpm for 15 minutes, then add 7 parts of leveling agent, 3 parts of defoaming agent, 3 parts of dispersant, 2 parts of magnesium sulfate, 1 part of magnesium oxide and 0.8 parts of antibacterial agent Put it into a disperser and disperse ultrasonically at a speed of 800 rpm for 15 minutes, then use a 4...

Embodiment 2

[0047] A method for making a projection screen, comprising the following steps:

[0048] (1) Provide a base layer, the material of the base layer is PVC, and the thickness of the base layer is 0.7mm;

[0049] (2) Deposit a protective layer on one side of the base layer, the protective layer is a titanium nitride coating, and its thickness is 0.7mm;

[0050] (3) Mix and stir 60 parts of polyester-modified silicone resin and 20 parts of absolute ethanol, raise the temperature to 50-60°C and keep for 5 minutes, then add 12 parts of glass microspheres, 5 parts of flame retardant, and 2 parts of thickener, Put it into a disperser and disperse ultrasonically for 5 minutes at a speed of 600 rpm, then add 4 parts of leveling agent, 6 parts of defoamer, 2 parts of dispersant, 1 part of magnesium sulfate, 2 parts of magnesium oxide and 1 part of bacteriostat Put it into a disperser and disperse ultrasonically at a speed of 800 rpm for 10 minutes, then use a 400-mesh filter to filter un...

Embodiment 3

[0053] A method for making a projection screen, comprising the following steps:

[0054] (1) Provide a base layer, the material of the base layer is a composite layer of PET and PVC film, and the thickness of the base layer is 1.1mm;

[0055] (2) Deposit a protective layer on one side of the base layer, the protective layer is a composite layer of a transparent silicone grease layer and a titanium nitride coating, and its thickness is 1mm;

[0056] (3) Mix and stir 55 parts of polyester-modified silicone resin and 25 parts of absolute ethanol, raise the temperature to 50-60°C and keep for 10 minutes, then add 11 parts of glass microspheres, 3 parts of flame retardant, and 2 parts of thickener, Put it into a disperser and disperse ultrasonically for 15 minutes at a speed of 600 rpm, then add 5 parts of leveling agent, 3 parts of defoamer, 2 parts of dispersant, 1 part of magnesium sulfate, 1 part of magnesium oxide and 0.5 parts of antibacterial agent Put it into a disperser a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com