A kind of adsorption porous coating material and its preparation method and application

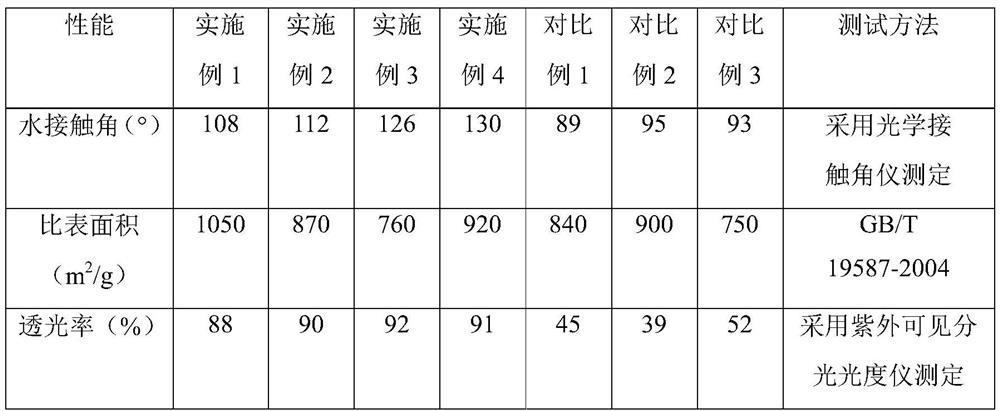

A porous coating and adsorption technology, applied in the field of adsorption porous coating materials and their preparation, can solve the problems of occlusion of optical lenses of imaging equipment, inability to perform effective shooting, poor light transmittance of the coating, etc., and achieves great application prospects, The effect of high hydrophobicity and good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation steps of porous adsorption material include the following:

[0026] Mix tetraethoxysilane, dimethyldimethoxysilane, hexadecyltrimethoxysilane, and isopropanol at a controlled temperature of 30°C at a volume ratio of 10:15:10:23 and stir evenly . After stirring for 30 min, hydrochloric acid (0.1 mol / L) was added to adjust the pH value to 3. After stirring for 2 h, continue to add ammonia water (5 mol / L) to adjust the pH value to 10. After stirring for 15 min, the mixed solution was poured into a closed container.

[0027] After the sample is formed, in order to prevent alcohol volatilization and surface cracking, it is necessary to add a certain amount of isopropanol to cover it for aging. The total aging time was 2 days.

[0028] The material obtained by aging is subjected to microwave drying to obtain a porous adsorption material. Finally, a layer of xylene derivatives is deposited by vapor deposition to improve the stability of the material.

[0...

Embodiment 2

[0031] The preparation steps of porous adsorption material include the following:

[0032] Mix tetraethoxysilane, dimethyldimethoxysilane, hexadecyltrimethoxysilane and isopropanol at a volume ratio of 8:15:13:20 at a controlled temperature of 30°C and stir evenly . After stirring for 30 min, acetic acid (1 mol / L) was added to adjust the pH value to 4. After stirring for 2 h, continue to add ammonia water (5 mol / L) to adjust the pH value to 9. After stirring for 15 min, the mixed solution was poured into an airtight container and gelled at room temperature.

[0033] After the sample is formed, in order to prevent the volatilization of isopropanol and the cracking of the gel surface, it is necessary to add a certain amount of isopropanol to cover it for aging. The total aging time was 3 days.

[0034] The wet gel obtained by aging is subjected to microwave drying to obtain a porous adsorption material. Finally, a layer of p-xylene derivatives is deposited by vapor depositi...

Embodiment 3

[0037] The preparation steps of porous adsorption material include the following:

[0038] Mix tetraethoxysilane, dimethyldimethoxysilane, hexadecyltrimethoxysilane and isopropanol at a volume ratio of 9:16:15:15 at a controlled temperature of 30°C and stir evenly . After stirring for 30 min, acetic acid (1 mol / L) was added to adjust the pH value to 5. After stirring for 2 h, continue to add ammonia water (5 mol / L) to adjust the pH value to 10. After stirring for 15 min, the mixed solution was poured into an airtight container and gelled at room temperature.

[0039] After the sample is formed, in order to prevent the isopropanol from volatilizing and cracking the surface, it is necessary to add a certain amount of isopropanol to cover it for aging. The total aging time was 3 days.

[0040] The wet gel obtained by aging is subjected to microwave drying to obtain a porous adsorption material. Finally, a layer of xylene derivatives is deposited by vapor deposition to improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com