Automatic and efficient production line for chains

An automated, production-line technology, applied in the direction of metal chains, etc., can solve the problems of inability to remove chain debris and grease, inability to ensure constant temperature of oil drums, low service life of sprockets, etc., to correct the chain frame, reduce tight links, extend The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

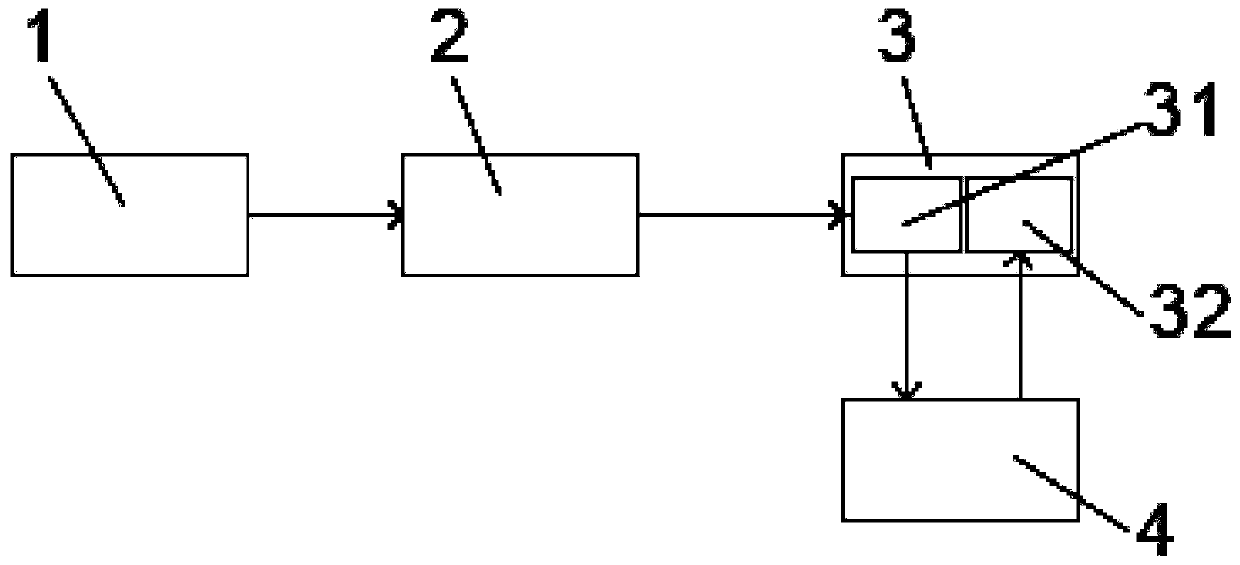

[0040] see Figure 1-11 , the present invention provides the following technical solutions: an automated high-efficiency chain production line, including a feeding assembly mechanism 1, a riveting head machine 2, a double static load pre-drawing and dismantling machine 3, a lubricating machine 4, a feeding assembly mechanism 1 and a riveting head machine 2 The double static load pre-tensioning joint dismantling machine 3 is mainly composed of a pre-tightening running-in area 31 and a joint dismantling area 32. The riveting machine 2 is connected to the pre-tightening running-in area 31. The lubricating machine 4 is connected, and the lubricating machine 4 is connected to the dismantling area 32;

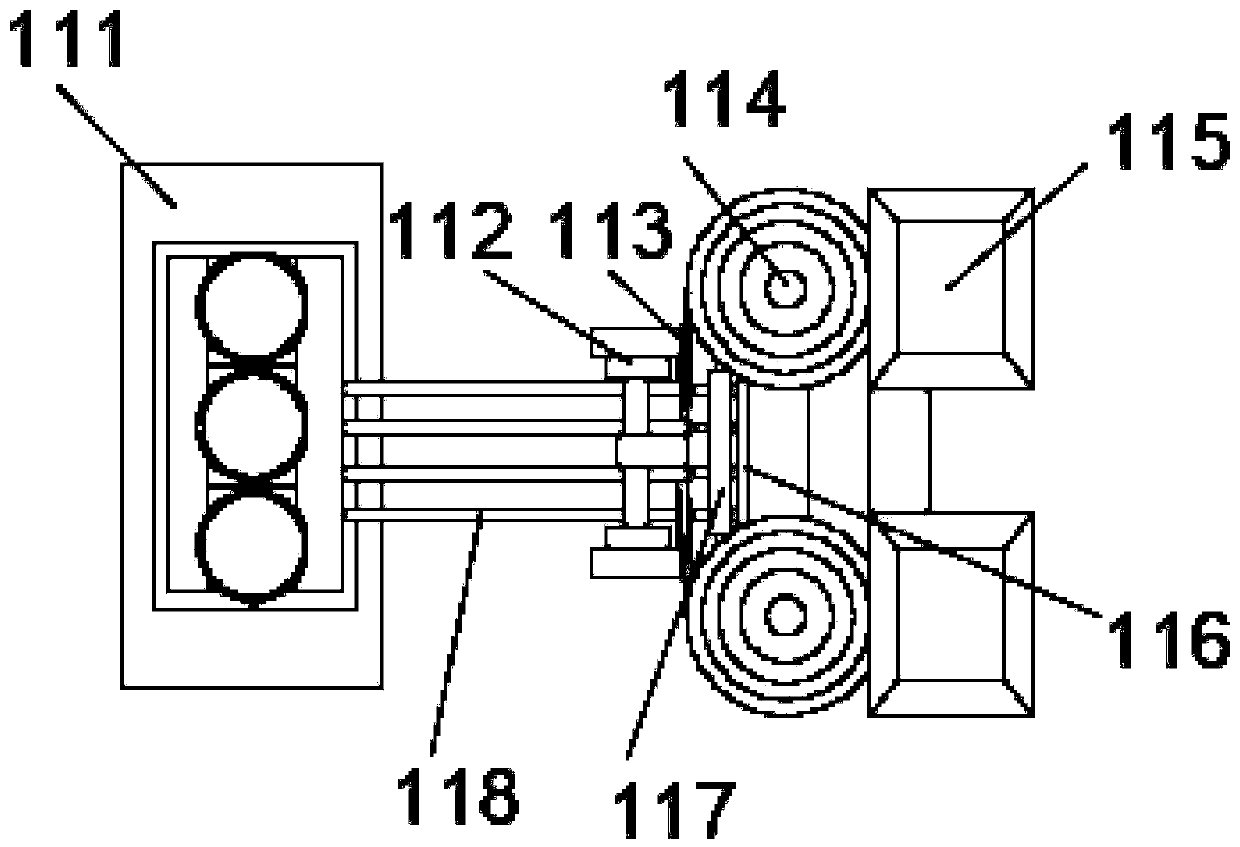

[0041] The feeding assembly mechanism 1 is mainly composed of an assembly machine 111, a feeder discharge pipe 113, a vibrating feeder 114, a feeding box 115, a conveying cylinder 116 and a workpiece feeding guide rail 118. The lower end of one side of the feeding box 115 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com