Auxiliary device for tire shaping and vulcanizing machines

An auxiliary device and vulcanizing machine technology, applied to tires, household appliances, other household appliances, etc., can solve the problems of easy deformation and dislocation of tire blanks, unsupported tread parts, large cylindricity deviation, etc., so as to improve the accuracy of tire shaping. and tire quality, reducing tire scrap rate and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

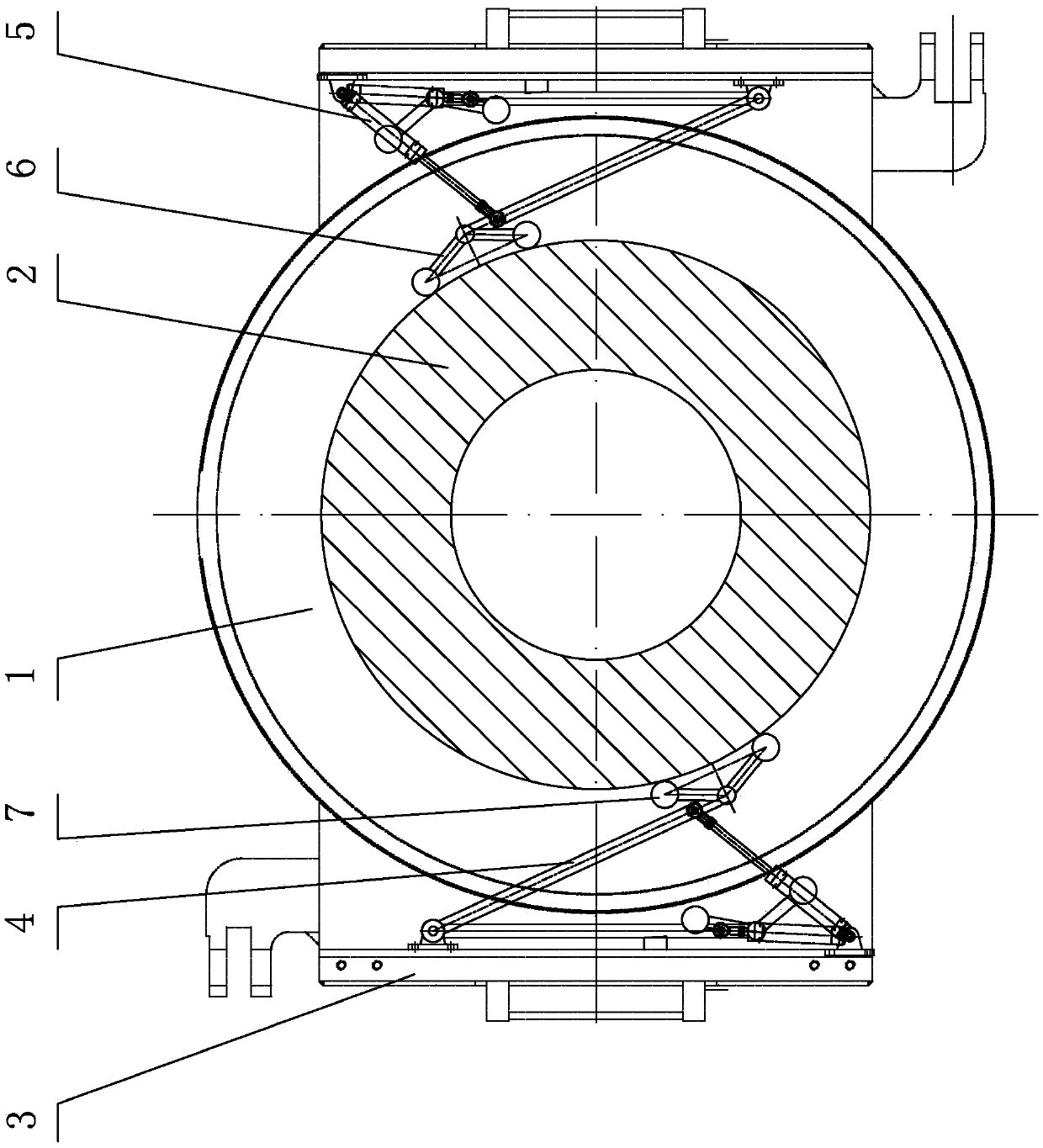

[0019] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0020] The stereotype auxiliary device of the tire shaping vulcanizer of the present invention includes left and right swing mechanisms arranged on the left and right base frames 3 of the vulcanizer on both sides of the vulcanization chamber mold loading position 1, and the left and right swing mechanisms are respectively provided with left and right armrest mechanisms After the tire blank 2 is located at the mold loading position 1 in the vulcanization chamber, the left and right swing mechanisms are synchronously swung in, and the left and right armrest mechanisms are obliquely supported on the (outer cylinder) tread of the tire blank 2 to make the tire blank 2. Blank 2 is centered at the center of mold loading position 1 in the vulcanization chamber. Before the capsule is finalized, the left and right swing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com