Rock triaxial test pressure cabin and test device thereof

A technology of triaxial test and pressure chamber, which is applied in the direction of measuring device, applying stable tension/pressure to test the strength of materials, instruments, etc. It can solve the problems of easy sticking to the clothes of the test personnel, unsophisticated, cumbersome test process, etc. , to achieve the effect of being convenient for outdoor and on-site testing, the overall structure is detachable, and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

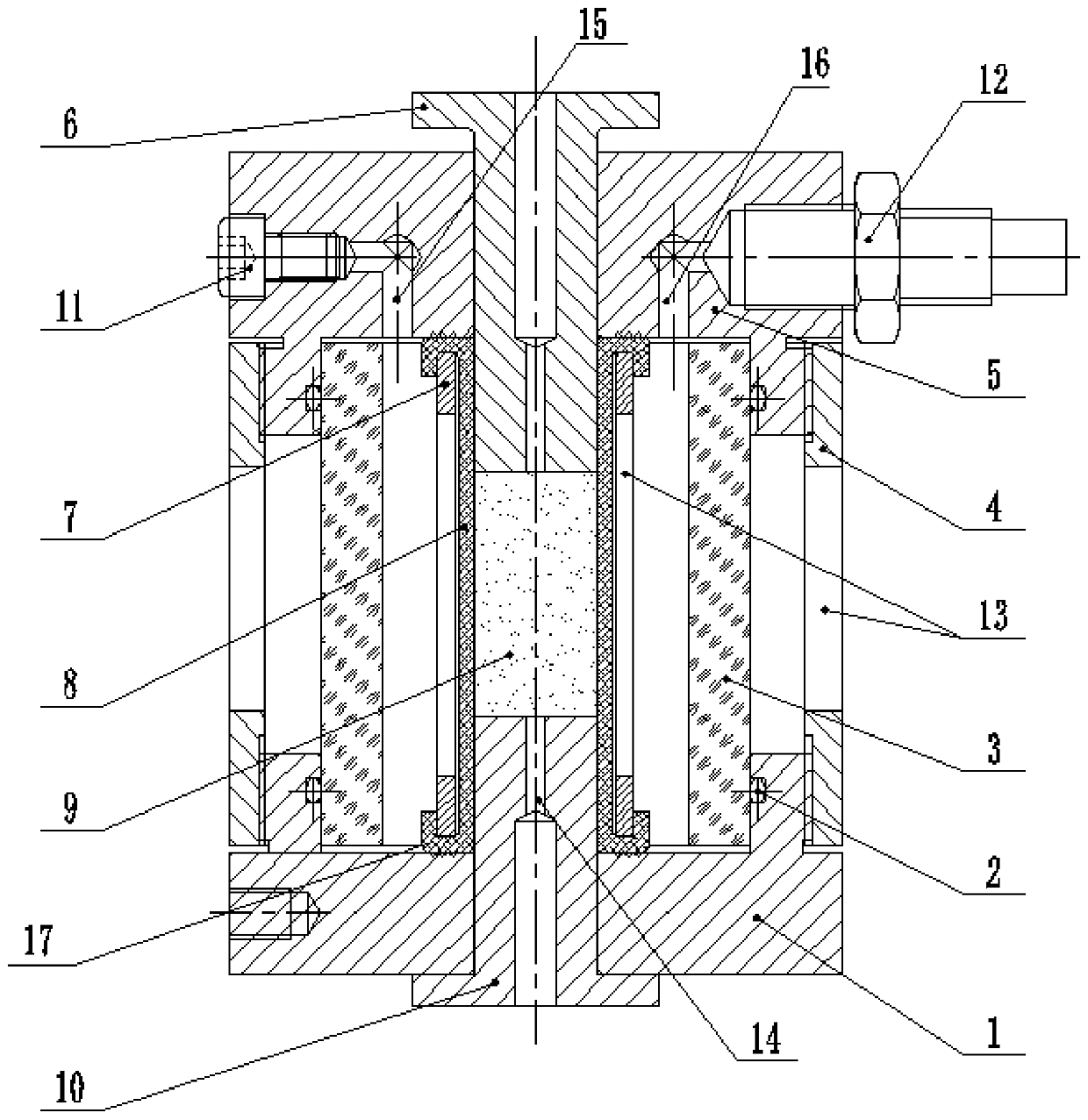

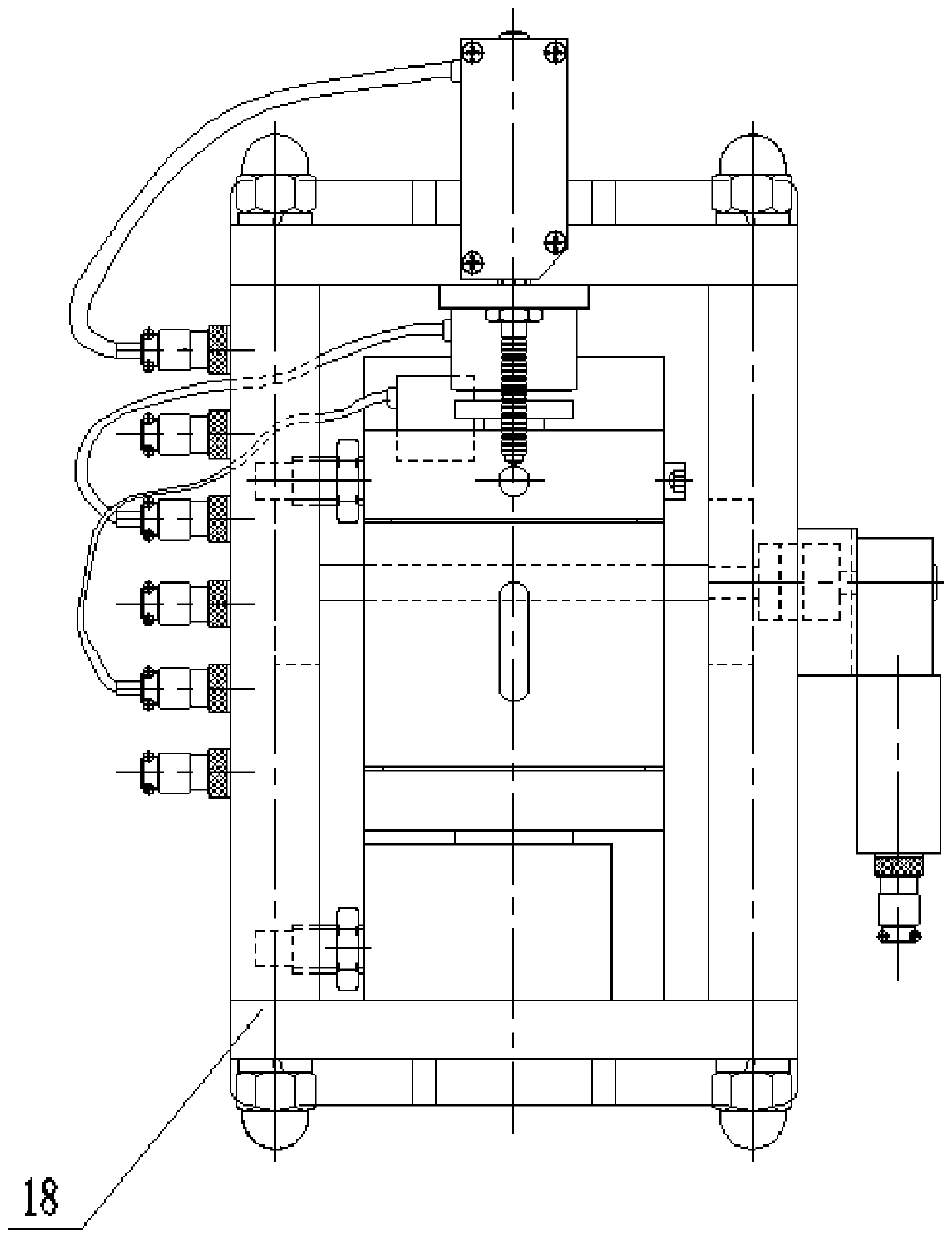

[0022] Reference Figure 1 to Figure 3 The embodiment of the pressure chamber for rock triaxial test and its testing device of the present invention will be further explained

[0023] A portable triaxial test device, comprising an upper end cover 5, a lower end cover 1 and an axial bearing cylinder 4. The upper end cover 5 and the lower end cover 1 are provided with threads at opposite ends, and the two ends of the axial bearing cylinder 4 are respectively The upper end cover 5 and the lower end cover 1 are screwed together, and the upper end cover 5 and the lower end are provided with through holes 3 with the same axis at their axes. The two through holes 3 are provided with an upper pressing rod 6 and a lower pressing rod 10, The inner side of the upper end cover 5 and the lower end cover 1 is provided with a pressure pipe 3, the pressure pipe 3 is provided with an oil isolation pipe 8, and both ends of the oil isolation pipe 8 are provided with flanges 17, so A support tube 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com