Meter-based automatic metering implementation method for steel coil scale

A technology of automatic measurement and realization method, applied in the field of steel coil weighing, which can solve the problems of incomplete guarantee of network security, inaccurate data confirmation, input errors, etc., so as to avoid information transmission errors, virus spread and network attacks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

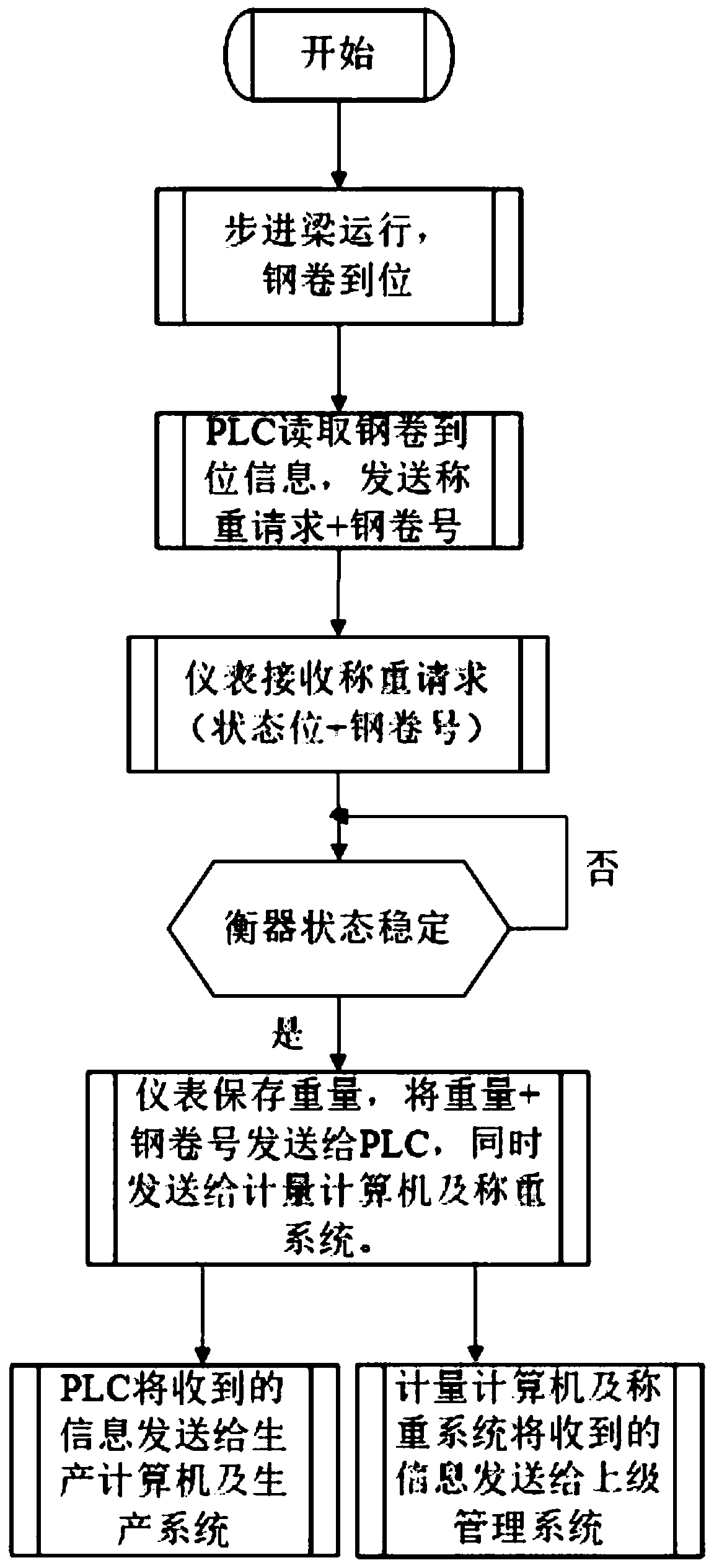

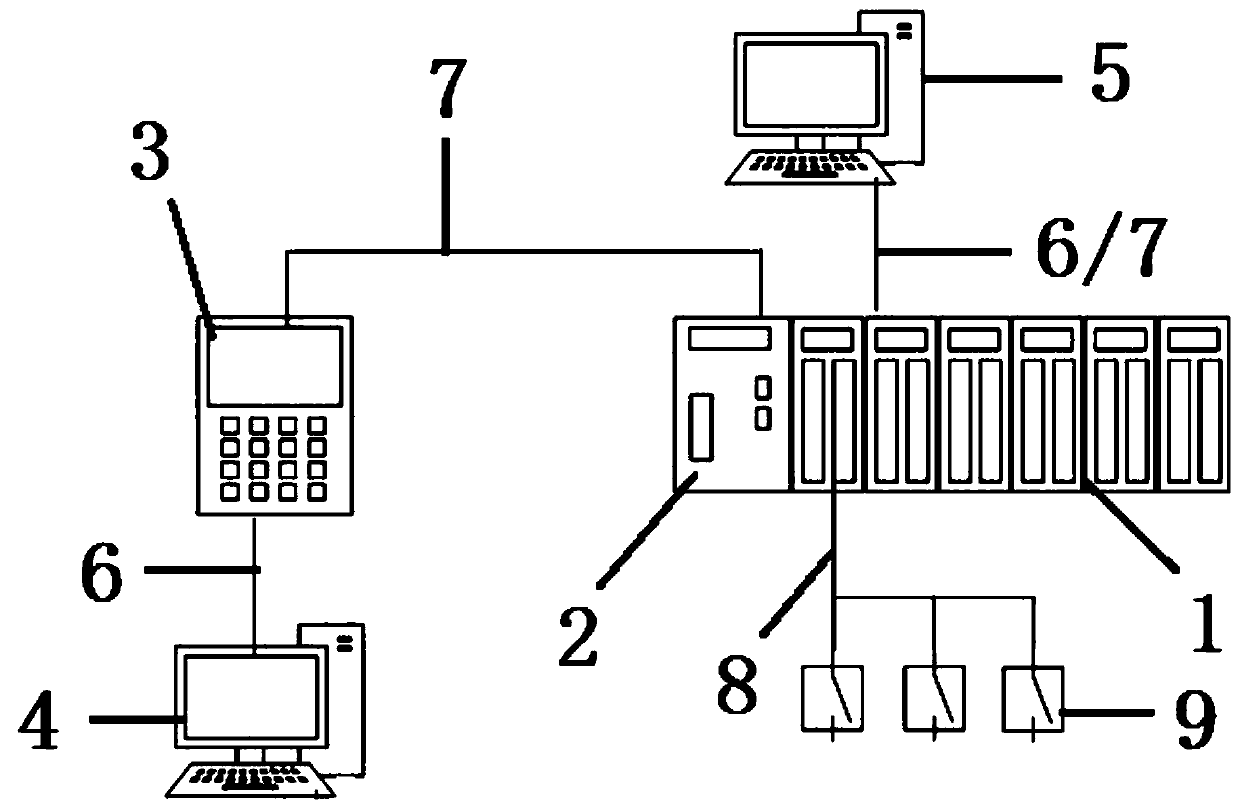

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described in further detail below with reference to the accompanying drawings in the embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0022] Explanation of technical terms involved in the present invention:

[0023] Coil scale: a weighing and measuring device actually installed on the walking beam, providing measurement information such as the weight of the item to be weighed;

[0024] PLC2: It is a programmable logic controller, which is a programmable controller, which can execute some logical operations, arithmetic operations, timing, counting and other instructions according to the pre-programmed and downloaded programs to its internal storage, and pass digital Or analog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com