Mechanical lifting start-stop control system for liquidometer water pump

A technology of start-stop control and liquid level gauge, which is used in pump control, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as melting and production accidents, and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the examples.

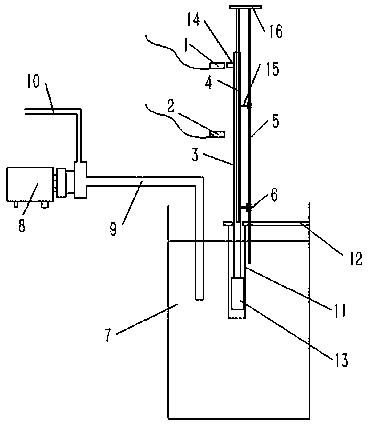

[0015] The invention discloses a start-stop control system for a mechanical lifting liquid level meter water pump, which comprises a lifting rod platform 12 arranged on the upper part of an acid circulation pit 7, an opening arranged on the lifting rod platform 12, connected to the bottom of the lifting rod platform 12 and The buoy guide barrel 11 located in the acid circulation pit 7, the buoy 13 arranged in the buoy guide barrel 11 and in contact with the acid liquid in the acid circulation pit 7, is connected to the top of the buoy 13 and passes through the opening of the lifting rod platform 12 and The hollow lifting rod 3 that extends out of the acid circulation pit 7, the lifting rod guide column 4 that is sleeved in the lifting rod 3 for the lifting rod 3 to move up and down, the contact point 14 that is arranged on the outer wall of the lifting rod 3, and is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com