Middle and small span bridge grouting miniature steel pipe pile, pile foundation and construction methods thereof

A construction method and technology of steel pipe piles, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of unrestricted use scope, incomplete construction process, and many operation steps, so as to solve the damage to the pile body and improve the Construction efficiency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

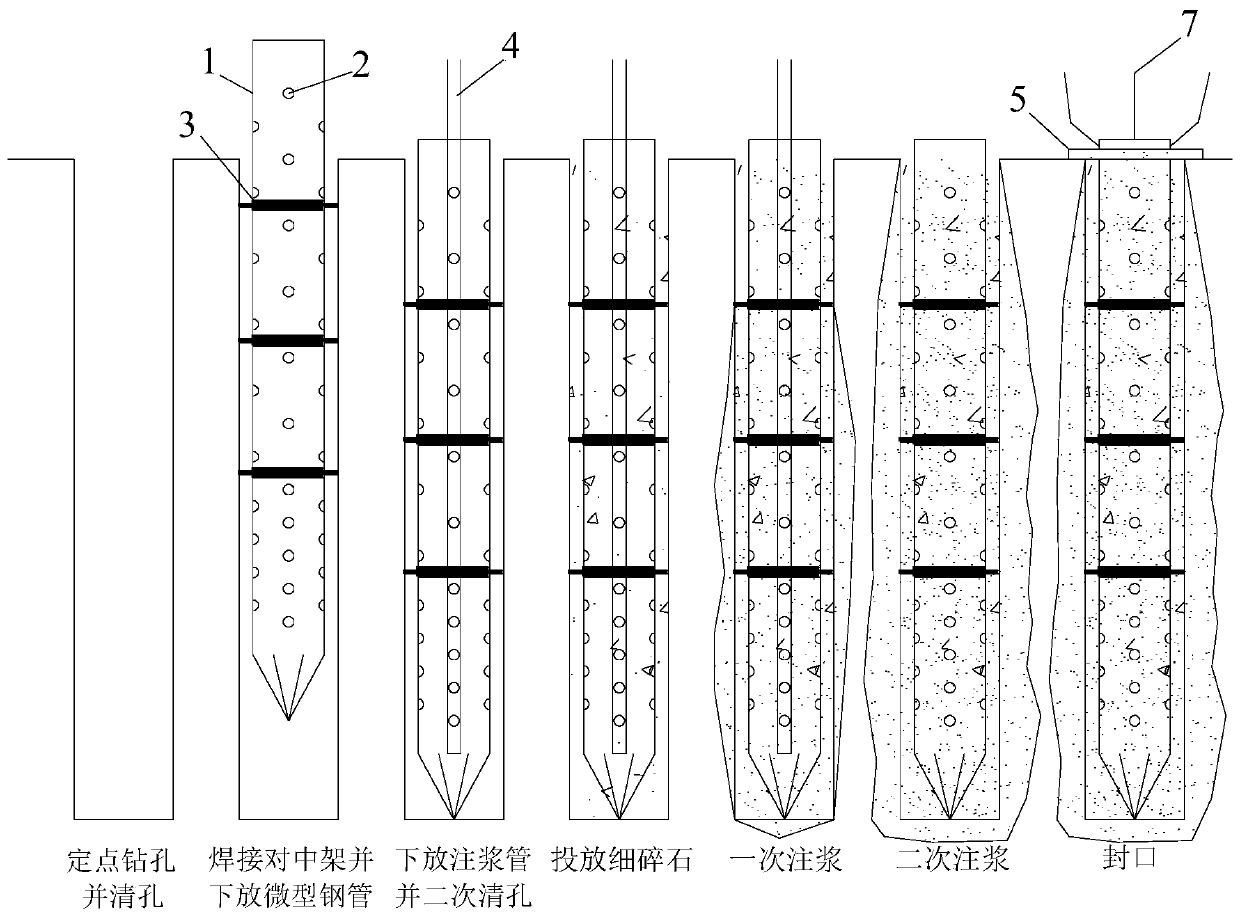

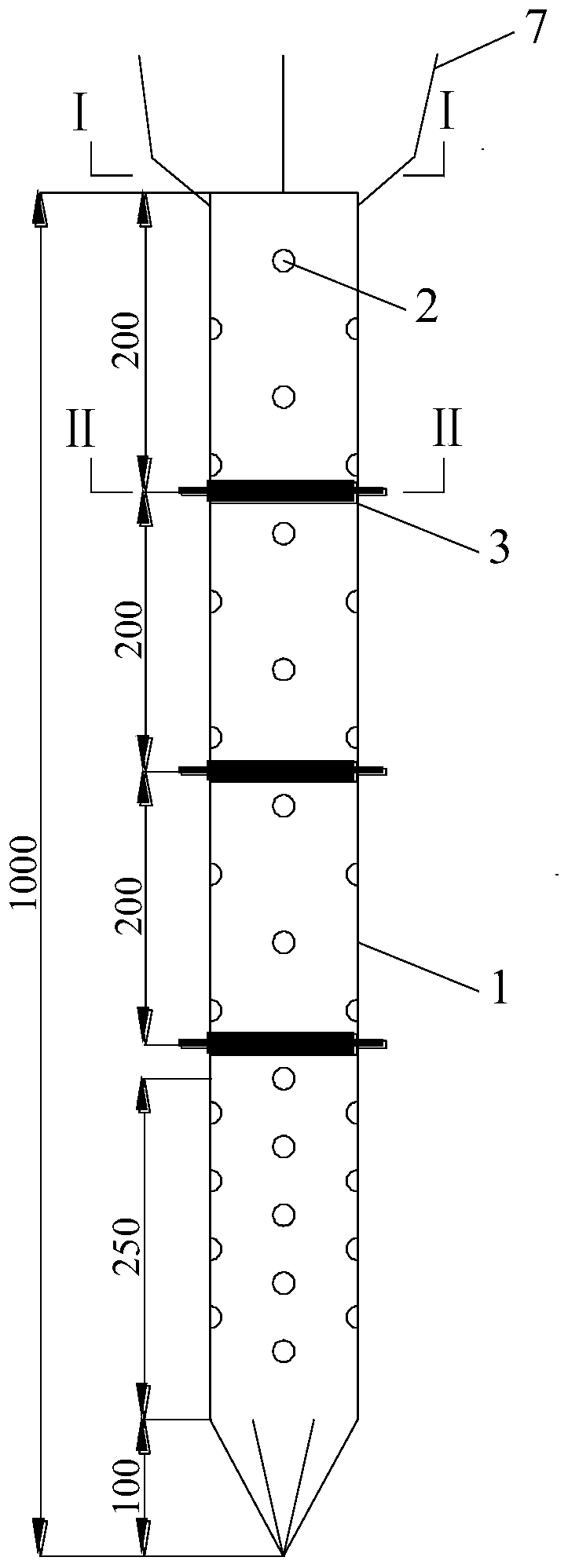

[0049] (1) Geological survey: use geological survey tools to find out the type and distribution of each rock formation in the construction foundation, measure the bearing capacity, porosity and water content of the stratum through which the designed pile length passes, and calculate the maximum range value of river scour;

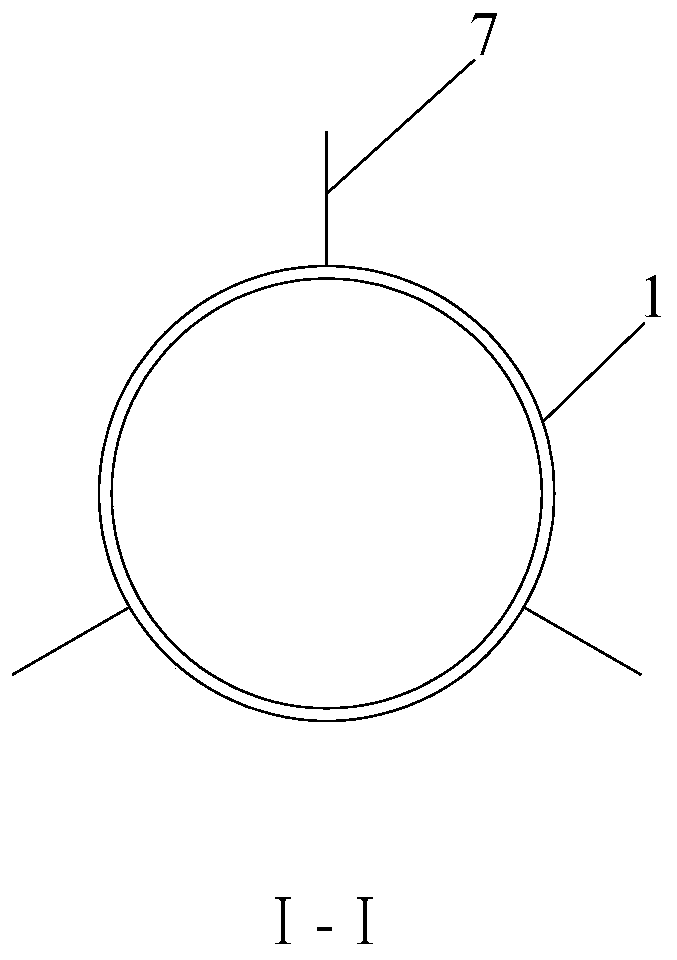

[0050] (2) Fixed-point drilling: According to the geological survey results, clean up and level the construction site, use measuring instruments to accurately position and number the pile holes according to the laid holes, determine the construction sequence, and select skip hole grouting; use a hole diameter of 150mm The small drilling rig enters the site, according to the design pile diameter of 150mm and pile length L=10m, drilling smoothly and vertically, the hole position deviation does not exceed 20mm, and the vertical inclination does not exceed 1°;

[0051] (3) Hole cleaning: Drill the hole to the design standard range, check the diameter, depth, pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com