Hydrophilic platform beam plate structure and construction method thereof

A beam-slab structure and water platform technology, applied in the field of hydrophilic platforms, can solve the problems of long on-site installation time, complex construction procedures, poor environmental adaptability, etc., and achieve the effects of improving construction efficiency, simple and efficient installation process, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

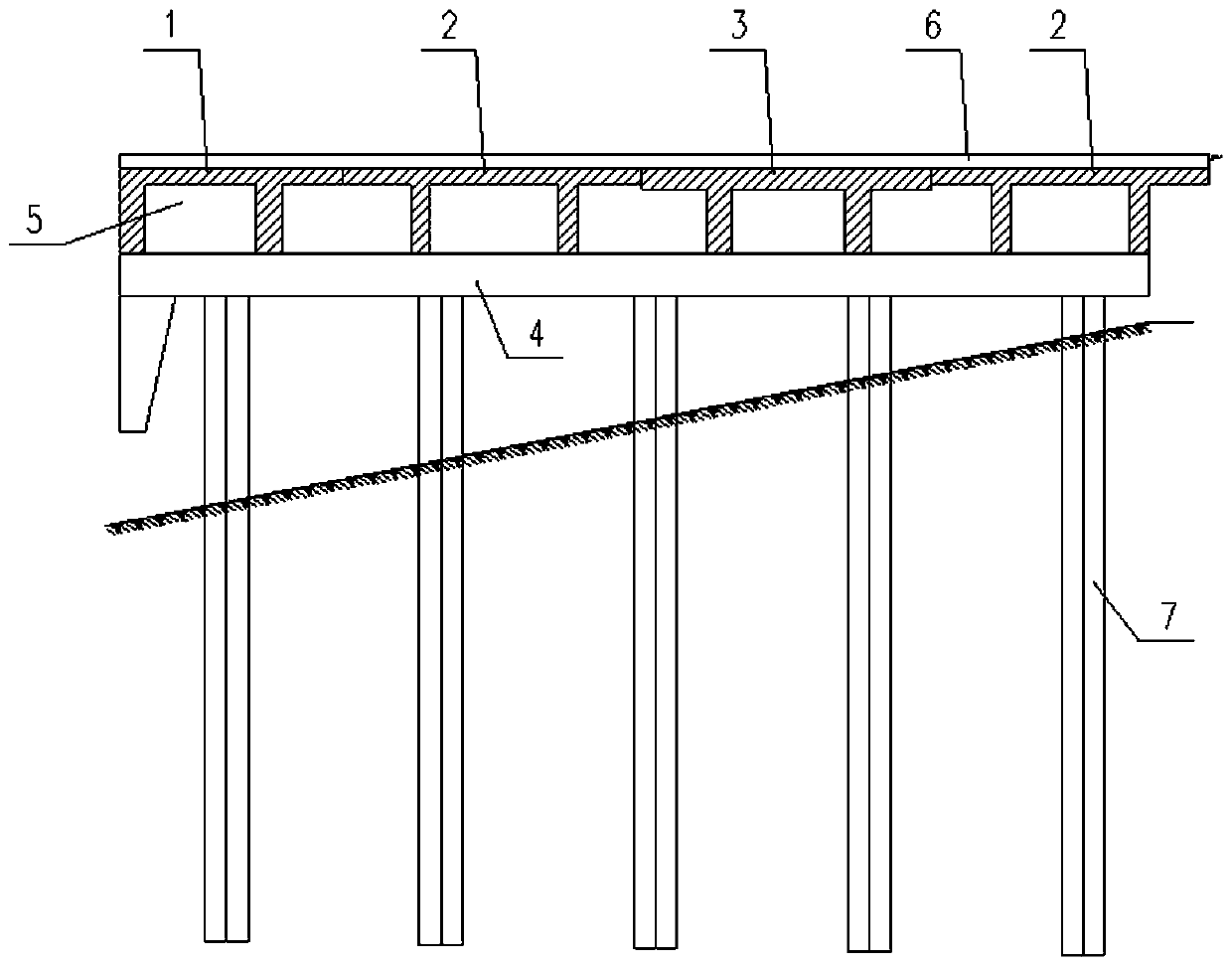

[0020] Such as figure 1 As shown, the hydrophilic platform includes three types of door-shaped prefabricated beam slabs (the first door-shaped prefabricated beam slab 1, the second door-shaped prefabricated beam slab 2, and the third door-shaped prefabricated beam slab 3), cast-in-place Beam 4, cast-in-place upper beam 5, cast-in-place panel 6, pile foundation 7. The hydrophilic platform is mainly subjected to crowd activity loads and gravity loads of landscape sketches, and the rear earth pressure is borne by the retaining wall. The stress conditions are simple and clear, and the requirements for the structure are relatively low. The use of standardized components is conducive to greatly reducing the complexity of design and construction, and improving the efficiency of engineering construction.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com