A kind of hot melt adhesive meeting the requirements of low atomization of automobiles and preparation method thereof

A low-atomization, hot-melt adhesive technology, applied in the direction of adhesives, wax adhesives, adhesive additives, etc., can solve the problem of hot-melt adhesive atomization exceeding the standard, to reduce volatilization, avoid contact, and reduce degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of the hot-melt adhesive that meets automobile low atomization requirement of the present invention comprises the following steps:

[0040] (a) Put thermoplastic elastomer, plasticizer and antioxidant into the reaction kettle and heat to 50°C-70°C and mix for 1 hour;

[0041] (b) Then heat up to 150°C under a vacuum state of -0.09Mpa to ~0.07Mpa, and melt the thermoplastic elastomer uniformly by stirring;

[0042] (c) Add fillers and plasticizers, stir evenly, add devolatilizer, continue to heat up to 200°C, and then stir for 5 to 30 minutes

[0043] (d) Finally, add the adsorbent, stir evenly, and then cool the briquette.

[0044] The technical scheme of the present invention utilizes a high degree of hydrogenation elastomer material to provide basic elasticity. A high degree of hydrogenation means very few double bonds and high temperature stability, and it is not easy to decompose small molecular substances, and it can be plasticized by ...

Embodiment 1

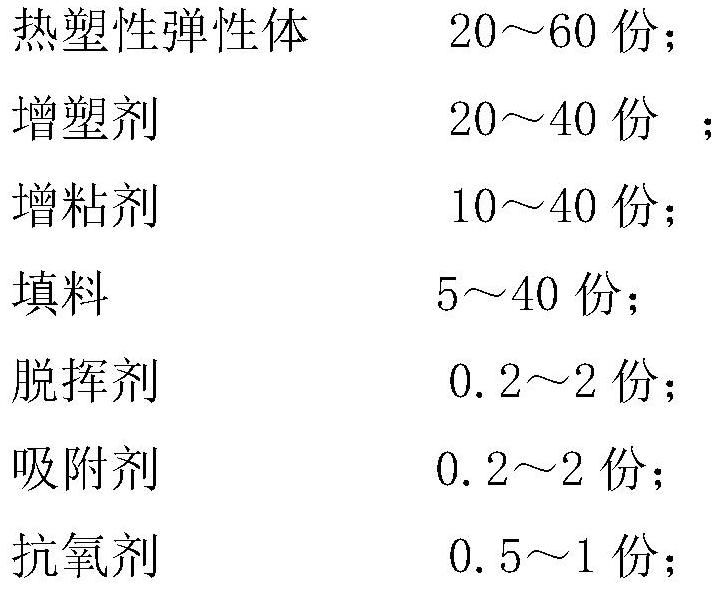

[0047] A hot-melt adhesive meeting the low atomization requirements of automobiles and a preparation method thereof, which mainly consists of the following raw materials in parts by weight:

[0048]

Embodiment 2

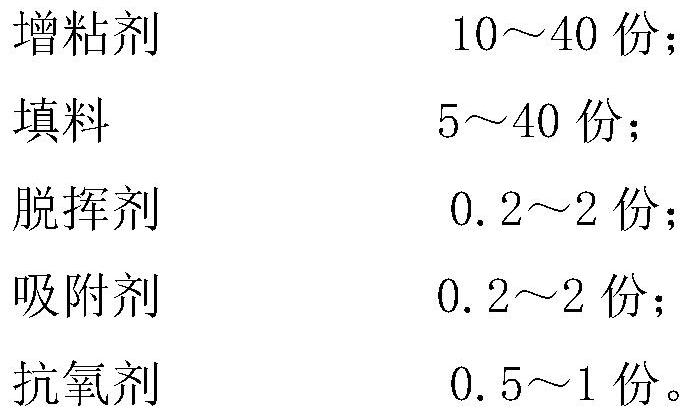

[0050] A hot-melt adhesive meeting the low atomization requirements of automobiles and a preparation method thereof, which mainly consists of the following raw materials in parts by weight:

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com