High-temperature-resistant modified acrylate pressure-sensitive adhesive and preparation method thereof

A technology of acrylate and pressure-sensitive adhesives, which is applied in the direction of adhesives, ester copolymer adhesives, adhesive types, etc., can solve the problems of high-temperature peeling force of pressure-sensitive adhesives, high production costs, and difficult control, etc., to achieve Solve the effect of high production cost, high production efficiency, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

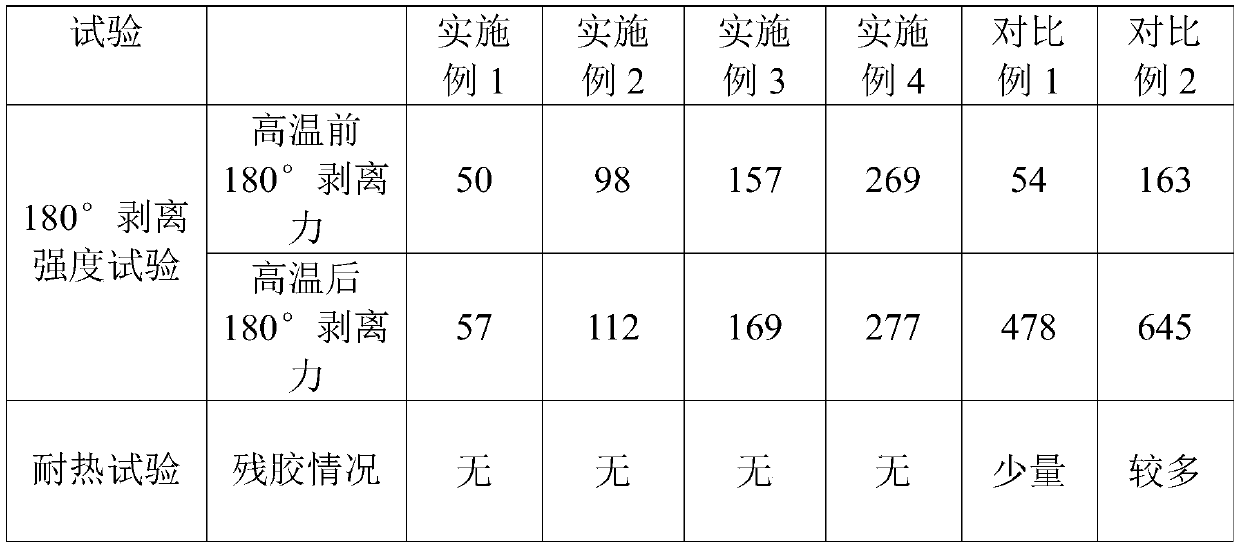

Examples

Embodiment 1

[0023] A high-temperature-resistant modified acrylate pressure-sensitive adhesive and a preparation method thereof, the preparation method comprising the following steps:

[0024] (1) Add 25.5g of butyl acrylate, 0.9g of octadecyl acrylate, 0.9g of isobornyl acrylate, 0.9g of acrylic acid, 0.9g of 2-hydroxybutyl acrylate, and trans-2-(4-biphenyl) 0.9g of vinylboronic acid, 0.075g of benzoyl peroxide, 55g of ethyl acetate, and 15g of toluene were mixed uniformly, and reacted at 78°C for 1 hour to obtain mixture 1;

[0025] (2) 25.5g of butyl acrylate, 0.9g of octadecyl acrylate, 0.9g of isobornyl acrylate, 0.9g of acrylic acid, 0.9g of 2-hydroxybutyl acrylate, trans-2-(4-biphenyl)ethylene 0.9 g of base boronic acid, 0.03 g of initiator benzoyl peroxide, and 40 g of ethyl acetate were mixed uniformly and added to a constant liquid funnel, uniformly added dropwise into the obtained mixture 1 within 1 hour, and kept for 30 minutes to obtain mixture 2;

[0026] (3) Add 34g of buty...

Embodiment 2

[0028] A high-temperature-resistant modified acrylate pressure-sensitive adhesive and a preparation method thereof, the preparation method comprising the following steps:

[0029] (1) Add 24.9g of butyl acrylate, 0.9g of lauryl acrylate, 1.2g of vinyl acetate, 0.9g of acrylic acid, 1.2g of 2-hydroxybutyl acrylate, and trans-2-(4-biphenyl)vinyl 0.9 g of boric acid, 0.075 g of benzoyl peroxide initiator, 55 g of ethyl acetate, and 15 g of toluene were mixed uniformly, and reacted at 80° C. for 1 h to obtain mixture 1;

[0030] (2) Add 24.9g of butyl acrylate, 0.9g of lauryl acrylate, 1.2g of vinyl acetate, 0.9g of acrylic acid, 1.2g of 2-hydroxybutyl acrylate, and trans-2-(4-biphenyl)vinylboronic acid 0.9g, initiator benzoyl peroxide 0.03g, and ethyl acetate 40g were mixed evenly and added to a constant liquid funnel, uniformly added dropwise into the obtained mixture 1 within 1 hour, and kept for 30 minutes to obtain mixture 2;

[0031] (3) Add 33.2g of butyl acrylate, 1.2g of...

Embodiment 3

[0033] A high-temperature-resistant modified acrylate pressure-sensitive adhesive and a preparation method thereof, the preparation method comprising the following steps:

[0034] (1) Add 24.3g of butyl acrylate, 0.9g of octadecyl acrylate, 0.9g of vinyl acetate, 1.8g of methacrylic acid, 1.2g of 2-hydroxybutyl acrylate, and trans-2-(4-biphenyl ) 0.9 g of vinylboronic acid, 0.075 g of benzoyl peroxide initiator, 55 g of ethyl acetate, and 15 g of toluene were uniformly mixed, and reacted at 82° C. for 1 h to obtain mixture 1;

[0035] (2) 24.3g of butyl acrylate, 0.9g of octadecyl acrylate, 0.9g of vinyl acetate, 0.9g of methacrylic acid, 1.2g of 2-hydroxybutyl acrylate, trans-2-(4-biphenyl) Mix 0.9 g of vinyl boronic acid, 0.03 g of benzoyl peroxide as an initiator, and 40 g of ethyl acetate, and add them into a constant liquid funnel, and drop them evenly into the obtained mixture 1 within 1 hour, and keep the reaction for 30 minutes to obtain mixture 2;

[0036] (3) Add 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com