Anaerobic-oxidation ditch-SACR combined deep denitrification system and process for sewage with high ammonia nitrogen content

A deep denitrification and oxidation ditch technology, applied in aerobic and anaerobic process treatment, aerobic process treatment, anaerobic digestion treatment and other directions, can solve the problem of limited effect of nitrogen removal, volume and dissolved oxygen concentration difficult to accurately control and other problems, to achieve the effect of low upgrading and transformation cost and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

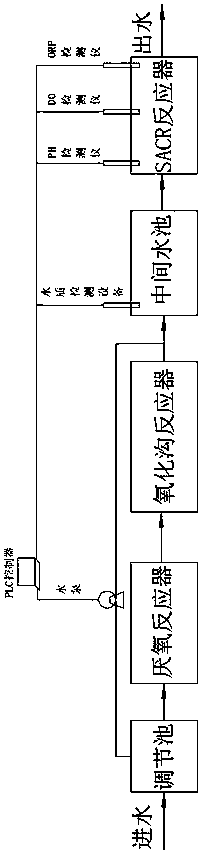

[0031] Example 1: An anaerobic-oxidation ditch-SACR combined deep denitrification system for high ammonia nitrogen sewage

[0032] Such as figure 1 As shown, an anaerobic-oxidation ditch-SACR combined deep denitrification system for high-ammonia nitrogen sewage, including a regulating tank, anaerobic reactor, oxidation ditch reactor, sedimentation tank, intermediate tank and SACR reaction connected in sequence through pipelines device; the outlet end of the regulating pool is connected with the inlet end of the intermediate pool through a pipeline; the pipeline is provided with a water pump for regulating the flow rate; the intermediate pool is provided with water quality detection equipment; the SACR reactor is provided with a pH detection device Instrument, DO detector, ORP detector, aeration equipment and agitator; also includes PLC controller, the PLC controller is respectively connected with water quality testing equipment, PH detector, DO detector, ORP detector, aeration...

Embodiment 2

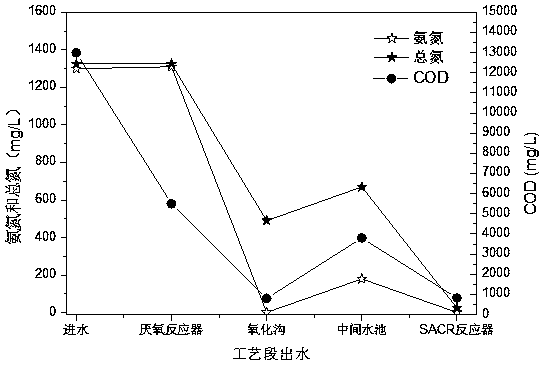

[0036] Example 2: An anaerobic-oxidation ditch-SACR combined deep denitrification process for high-ammonia nitrogen sewage

[0037] The technology in this embodiment is based on the system in embodiment 1, and the anaerobic reactor is a UASB reactor; the volume of the oxidation ditch reactor=(high ammonia nitrogen sewage raw water total nitrogen concentration value / 50 * 30 * sewage per hour output value) m3; the unit of total nitrogen concentration in high ammonia nitrogen sewage raw water is mg / L, and the unit of sewage output per hour is m 3 ;SACR volume = (total nitrogen concentration value of high ammonia nitrogen sewage raw water / 50×20×hourly sewage production value) m 3 ; The unit of total nitrogen concentration in high ammonia nitrogen sewage raw water is mg / L, and the unit of sewage output per hour is m 3 .

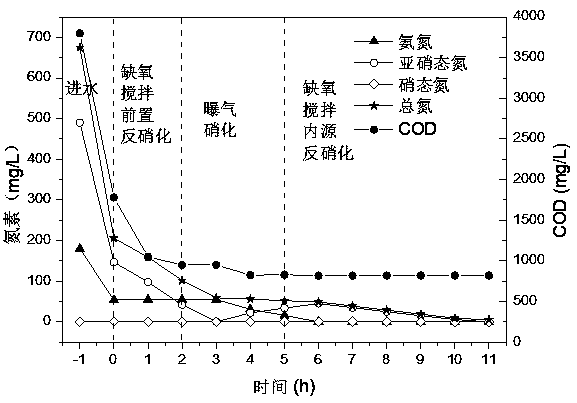

[0038] An anaerobic-oxidation ditch-SACR combined high ammonia nitrogen sewage deep denitrification process, comprising the following steps:

[0039] (1) High ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com