A sbbr-sbr switching landfill leachate deep denitrification process

A technology for deep denitrification of landfill leachate, applied in the field of SBBR-SBR switching landfill leachate deep denitrification process, can solve the problems of high treatment cost, difficulty in denitrification rate reaching 90%, and low denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

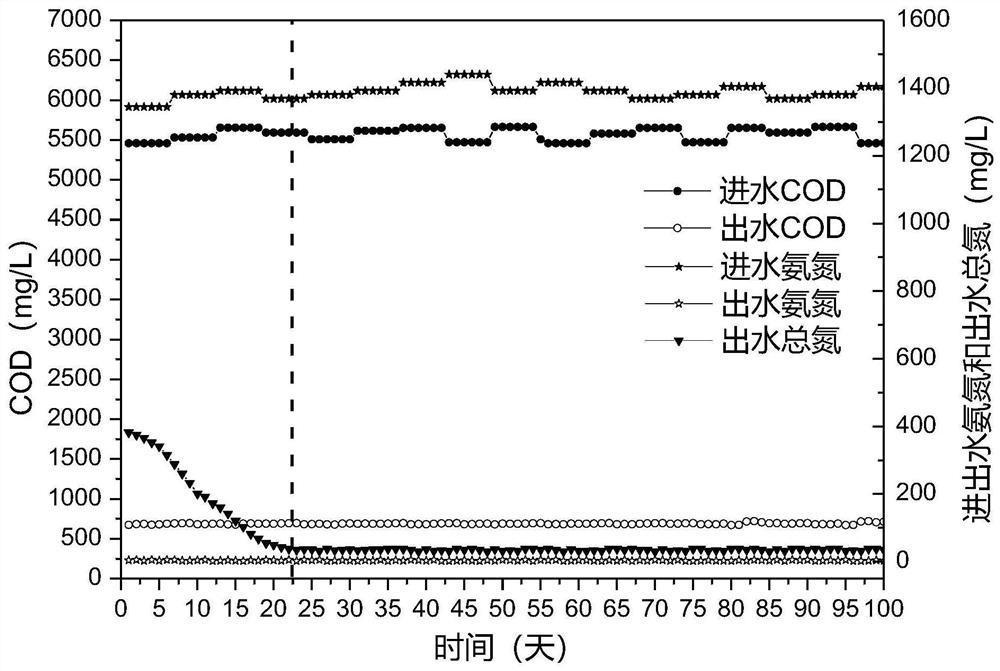

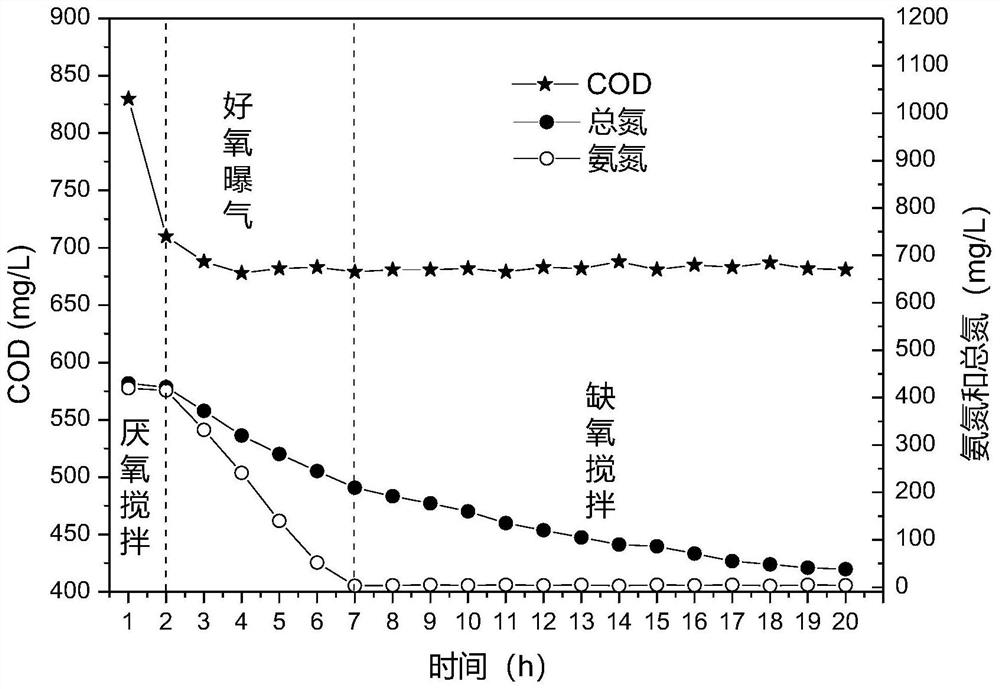

[0024] Select leachate with COD of 5400±200mg / L and ammonia nitrogen concentration of 1350±100mg / L for treatment.

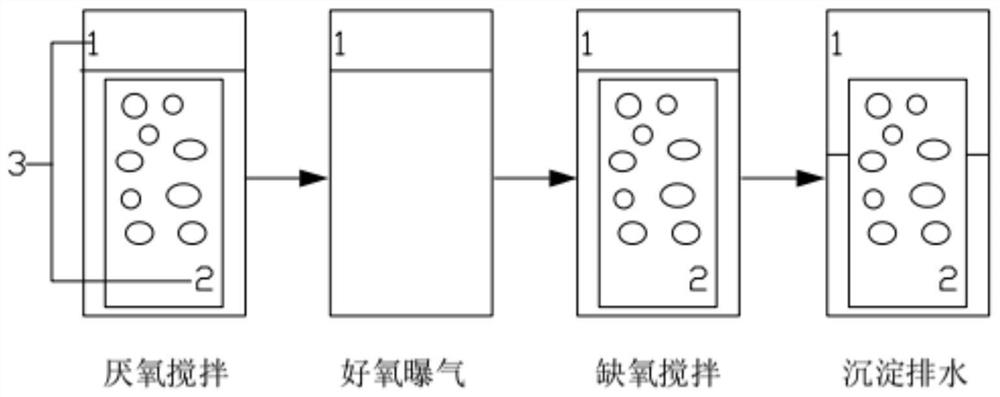

[0025] Such as figure 1 As shown, a SBBR-SBR switching landfill leachate deep denitrification process, the processing device used in the process includes an SBR reactor 1, a stuffing box 2 placed in the SBR reactor, used to react the stuffing box 2 from the SBR The hoisting device hoisted out of the device 1 and the clear water tank used to store the stuffing box 2 hoisted out, the SBBR-SBR switching type landfill leachate deep denitrification process includes the following steps:

[0026] (1) The stuffing box 2 is hoisted by the lifting device and put into the SBR reactor 1 to form an SBBR reactor. After the landfill leachate enters the SBBR reactor 3, anaerobic stirring is performed first, and the stirring time is 1 hour;

[0027] (2) Step (1) After the stirring is completed, the stuffing box 2 is lifted by the lifting device and put into the clear water tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com