Full-automatic neutralizing treatment system and method for alkaline sewage generated by concrete mixing plant

An alkaline sewage, fully automated technology, used in water/sludge/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, excessive water quality, corrosion of equipment, etc. Effects of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Fully automatic neutralization treatment of alkaline sewage generated by concrete mixing plants:

[0059] 5000L of alkaline sewage, the initial pH value is 13, and the solid content is 0.43%;

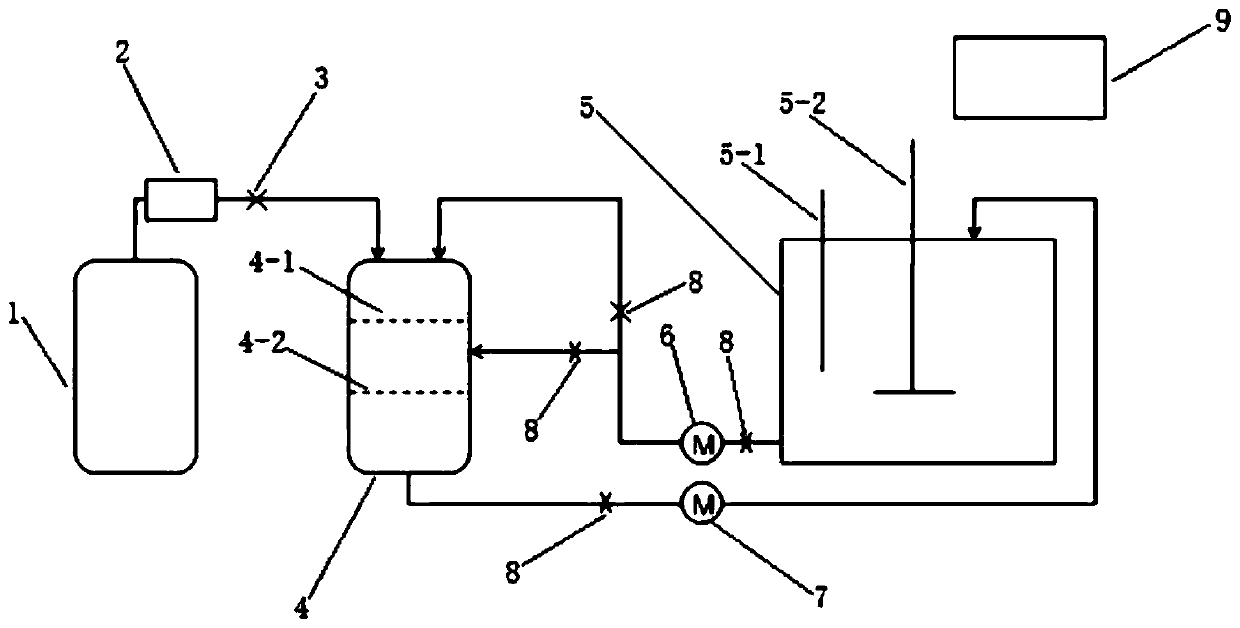

[0060] start up figure 1 The fully automated neutralization treatment system shown, CO 2 Liquid CO in storage tanks 2 by CO 2 The vaporizer is gasified, the carbon dioxide gas flow is 120L / min, and enters the CO 2 spray tower;

[0061] Alkaline sewage flows out from the alkaline sewage tank, respectively, as for CO 2 Spray above the primary spray plate and the secondary spray plate of the spray tower, and at the same time 2 CO in the spray tower 2 Neutralization is carried out, and the sewage treatment liquid obtained by neutralization is returned to the alkaline sewage tank, and the flow rate of the inlet pump and the return pump are both 20m 3 / h; the pH electronic monitor monitors the pH of the sewage in the alkaline sewage pool in real time, and transmits the monitori...

Embodiment 2

[0064] Fully automatic neutralization treatment of alkaline sewage generated by concrete mixing plants:

[0065] Alkaline sewage 6500L, initial pH value 13.2, solid content 0.62%;

[0066] start up figure 1 The fully automated neutralization treatment system shown, CO 2 Liquid CO in storage tanks 2 by CO 2 The vaporizer is gasified, the carbon dioxide gas flow rate is 150L / min, and enters the CO 2 spray tower;

[0067] Alkaline sewage flows out from the alkaline sewage tank, respectively, as for CO 2 Spray above the primary spray plate and the secondary spray plate of the spray tower, and at the same time 2 CO in the spray tower 2 Neutralization is carried out, and the sewage treatment liquid obtained by neutralization is returned to the alkaline sewage tank, and the flow rate of the inlet pump and the return pump are both 20m 3 / h; the pH electronic monitor monitors the pH of the sewage in the alkaline sewage pool in real time, and transmits the monitoring results to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumetric flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com