A method of mineralizing and cementing uranium tailings by using montmorillonite/carbonate mineralizing bacteria

A technology of carbonate and montmorillonite, which is applied in the removal of solid waste, etc., can solve the problems of high cost and inability to solve the diffusion of radioactive elements and radon gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

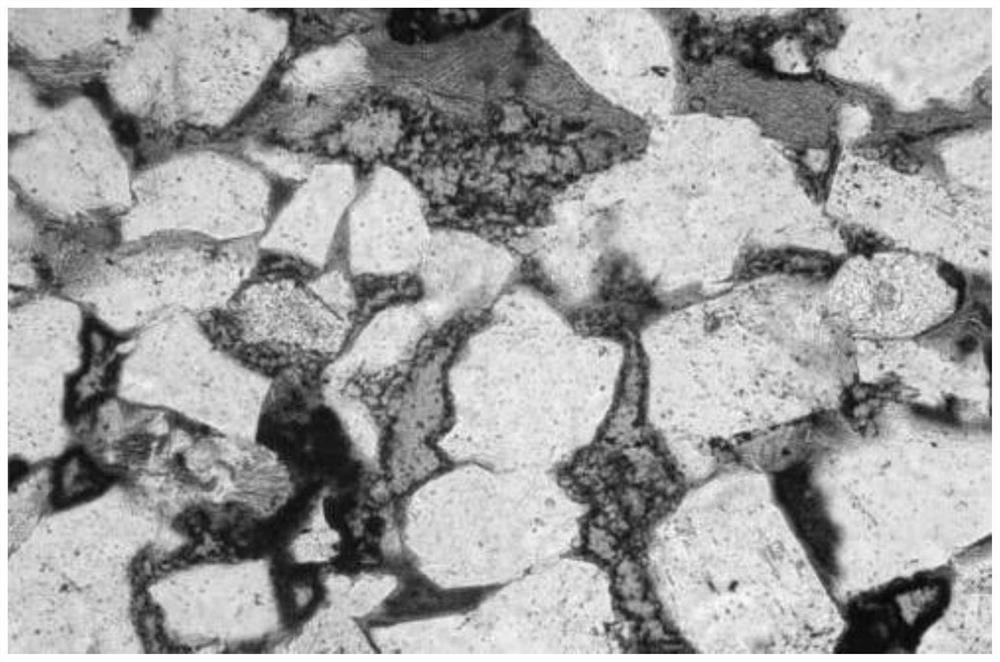

Image

Examples

Embodiment 1

[0027] Step 1. By using a strong alkaline nutrient solution with a pH value of 10, stress induces the carbonate mineralization strain, and selects a microwave with a microwave frequency of 2200MHZ and a power of 350W to induce the carbonate mineralization strain by microwave irradiation, and irradiates The duration is 6 minutes, from which high-efficiency carbonate mineralization strains are cultivated, and their biological properties are studied, and their physiology and biochemistry, growth and reproduction laws and culture characteristics are investigated;

[0028] Step 2. Expand the screened and domesticated high-efficiency carbonate mineralization strains in the culture solution to prepare high-concentration bacteria solution; during the cultivation process, keep the shaking table at a speed of 200 revolutions per minute and the cultivation temperature at 25 ℃, the incubation time is 24 hours. After the incubation, use a centrifuge to centrifuge the bacterial liquid at 350...

Embodiment 2

[0035]Step 1. By using a strong alkaline nutrient solution with a pH value of 10, stress induces the carbonate mineralization strain, and selects a microwave with a microwave frequency of 2200MHZ and a power of 350W to induce the carbonate mineralization strain by microwave irradiation, and irradiates The duration is 6 minutes, from which high-efficiency carbonate mineralization strains are cultivated, and their biological properties are studied, and their physiology and biochemistry, growth and reproduction laws and culture characteristics are investigated;

[0036] Step 2. Expand the screened and domesticated high-efficiency carbonate mineralization strains in the culture medium to prepare a high-concentration bacterial solution; during the cultivation process, keep the shaking table at a speed of 200 revolutions per minute and the cultivation temperature at 30 ℃, the incubation time is 24 hours. After the incubation, use a centrifuge to centrifuge the bacterial liquid at 350...

Embodiment 3

[0043] Step 1. By using a strong alkaline nutrient solution with a pH value of 10, stress induces the carbonate mineralization strain, and selects a microwave with a microwave frequency of 2200MHZ and a power of 350W to induce the carbonate mineralization strain by microwave irradiation, and irradiates The duration is 6 minutes, from which high-efficiency carbonate mineralization strains are cultivated, and their biological properties are studied, and their physiology and biochemistry, growth and reproduction laws and culture characteristics are investigated;

[0044] Step 2. Expand the screened and domesticated high-efficiency carbonate mineralization strains in the culture solution to prepare high-concentration bacteria solution; during the cultivation process, keep the shaking table at a speed of 200 revolutions per minute and the cultivation temperature at 25 ℃, the incubation time is 24 hours. After the incubation, use a centrifuge to centrifuge the bacterial liquid at 350...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com