Method for sealing of furniture plate groove body and numerical control equipment for realizing same

A numerical control equipment and plate technology, applied in the field of plate processing, can solve the problems of loss of sealing free formaldehyde, release of adhesive odor, high processing efficiency, and achieve high processing efficiency by improving wax spray processing efficiency, environmental protection level and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

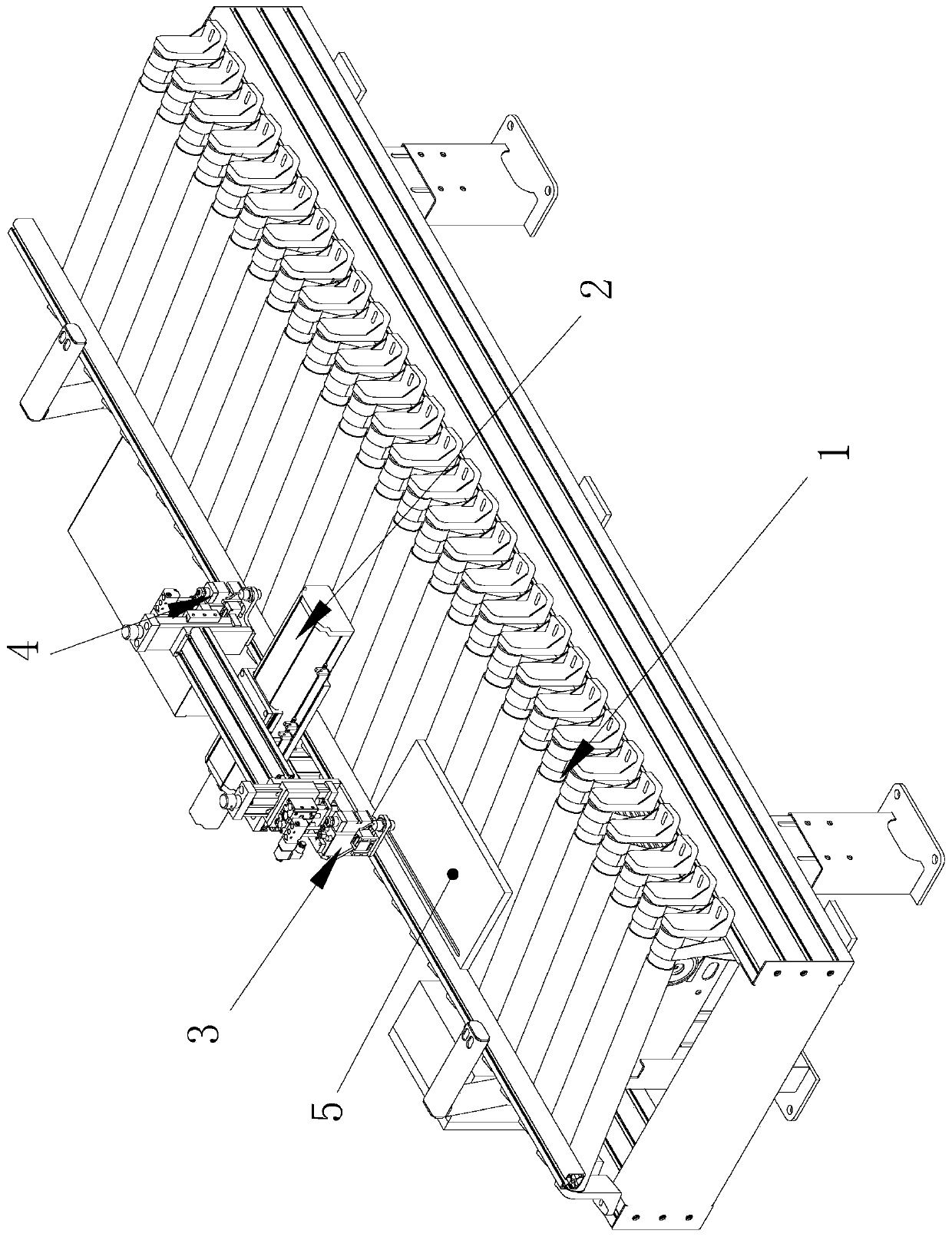

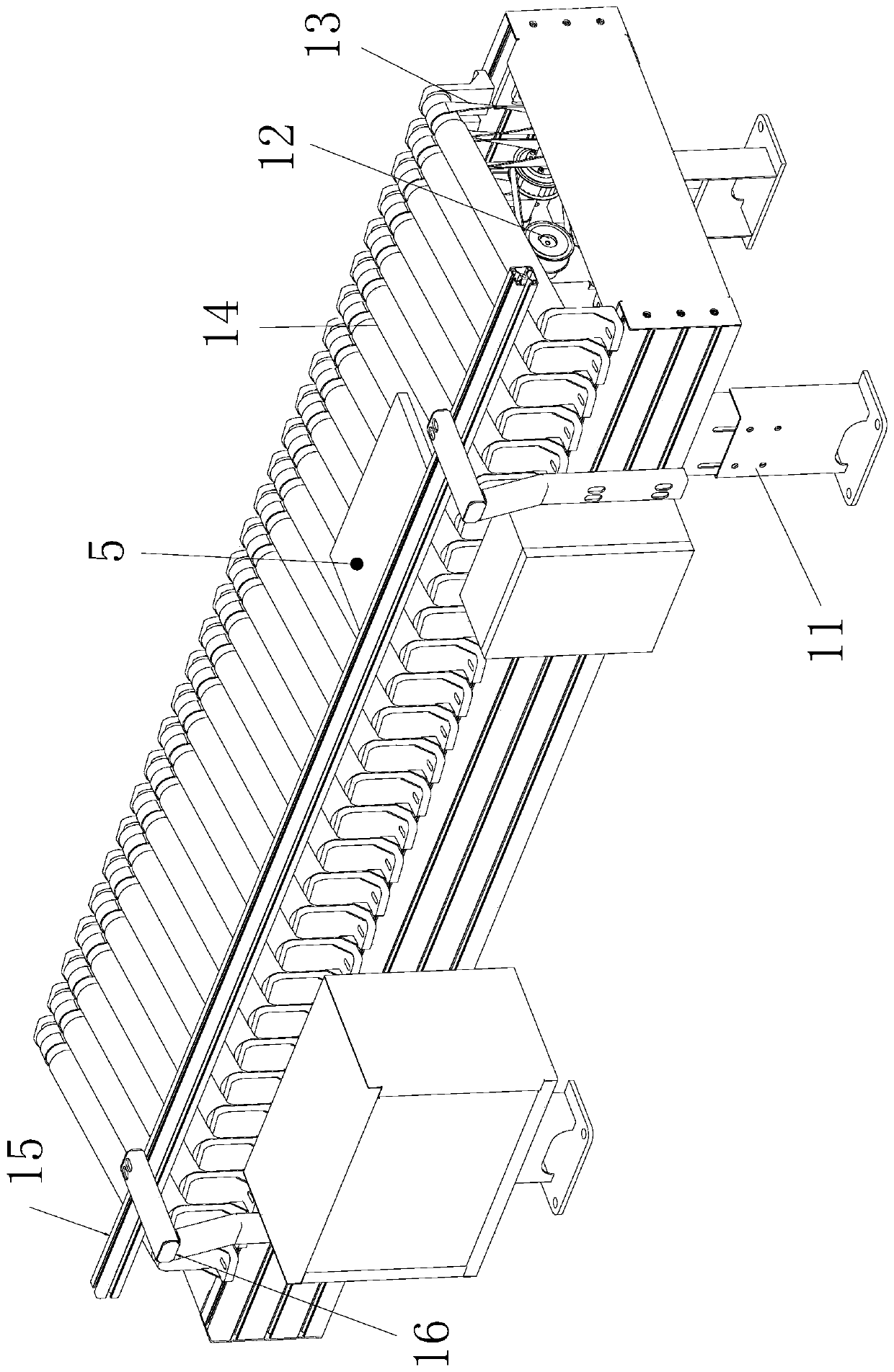

Embodiment 1

[0050] This embodiment is a method for sealing the furniture board tank body. The inside of the board tank body is sprayed with sealing wax to form a wax layer on the cut surface of the board tank body to achieve sealing, thereby preventing the release of free formaldehyde and adhesive odor inside the board material. out.

[0051] The method of the invention forms a wax layer on the cutting surface of the plate tank by spraying sealing wax inside the plate tank, effectively preventing the release of free formaldehyde and adhesive odor, further improving the environmental protection level of the plate, with simple process and high processing efficiency .

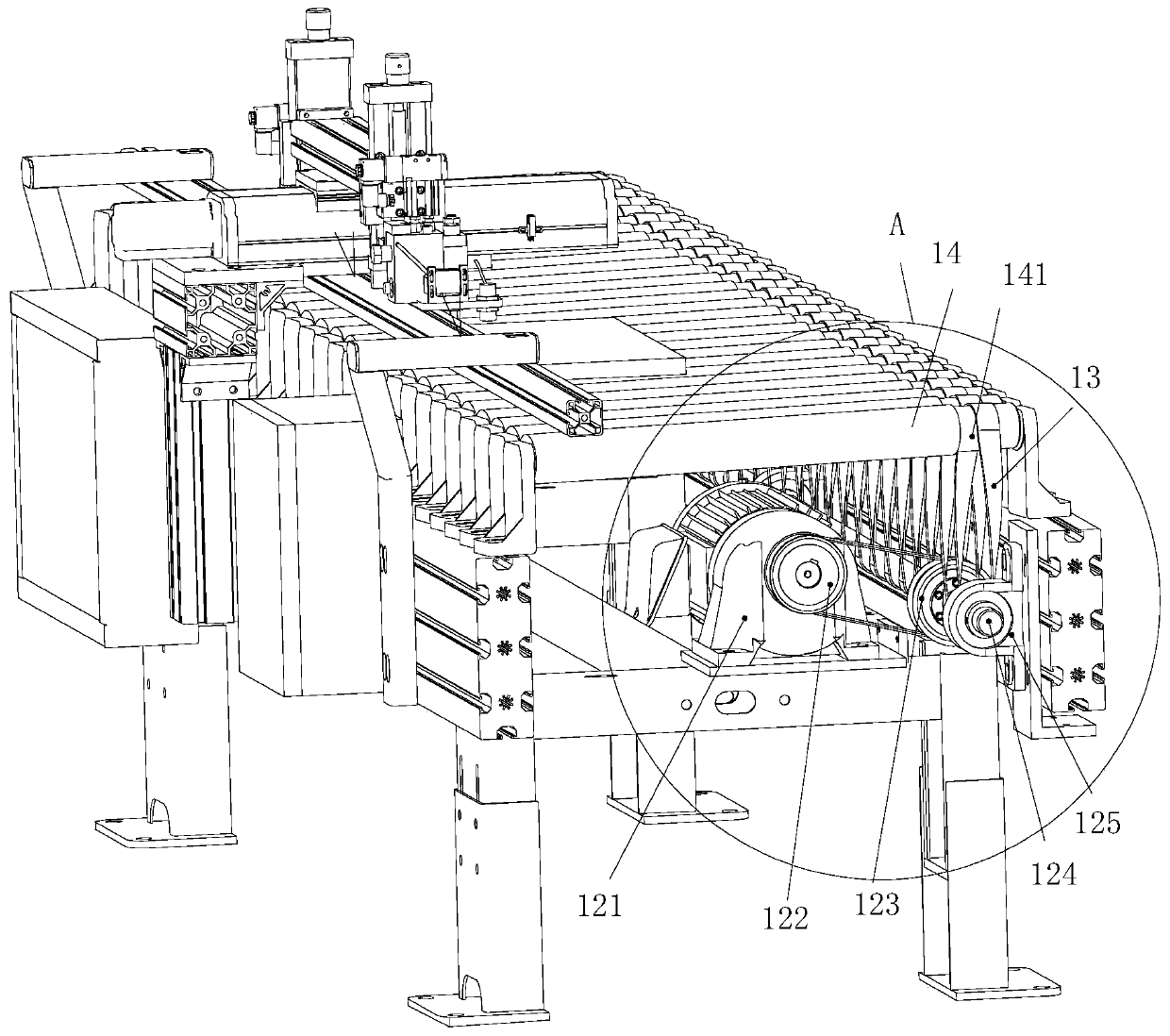

[0052] Preferably, the plate is transported and positioned, and the length direction of the plate tank body is consistent with the plate conveying direction; the side processing device and the bottom surface processing device are used for wax spraying processing; when the plate tank body moves below the side processing device...

Embodiment 2

[0084] This embodiment is a numerical control device, and the difference from Embodiment 1 is that in this embodiment, a laser scanning sensor is used instead of a laser ranging sensor, and the laser scanning sensor detects the information of the plate groove. The plate tank information includes the position of the plate tank, the length and width of the plate tank, the depth of the plate tank, the distance between the plate tank and the edge of the plate, and the thickness of the plate. The work of Sanwa Wax Injection Mechanism provides data information. The data information is automatically obtained, without the need for pre-identification of the plate. The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com