Method for preparing water-cured ripe tobacco leaves in shading environment

A modulation method and technology of tobacco leaves, which are applied in the field of tobacco leaf maturity, can solve problems such as heap stuffiness and suffocation, insufficient ripening after modulation, and poor uniformity of tobacco leaves, and achieve the effects of improving physical properties, maintaining physiological metabolism, and improving curing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] On June 2, 1990, in Tiantou Village, Chishui Township, Zhangping City, Fujian Province, a piece of G80 tobacco field was planned to be used for hybrid rice seed production. Because the male parent of hybrid rice seed production must be transplanted in advance to ensure that it is consistent with the female parent at the flowering stage, and at this time the field maturity of tobacco leaves is very different from the maturity of normal harvesting. Therefore, farmers prepare to remove the tobacco plants with the remaining 6-10 tobacco leaves after barely harvesting a part of the middle leaves. In order to reduce the waste loss, the following 6 treatment experiments were carried out:

[0057] 01) After cutting off part of the root system of the tobacco plant, move the soil into a small ditch for water cultivation;

[0058] 02) After cutting off part of the root system of the tobacco plant, move the soil into a small ditch for water cultivation, and wrap the tobacco plant ...

Embodiment 2

[0070] In order to solve the problems of insufficient maturity of the upper tobacco leaves, poor usability, and unsalable market in recent years, on June 8, 2019, in Chishui Village, Chishui Township, Zhangping City, Fujian Province, on the basis of the experimental conclusions obtained in Example 1, the present invention was reproduced. verify.

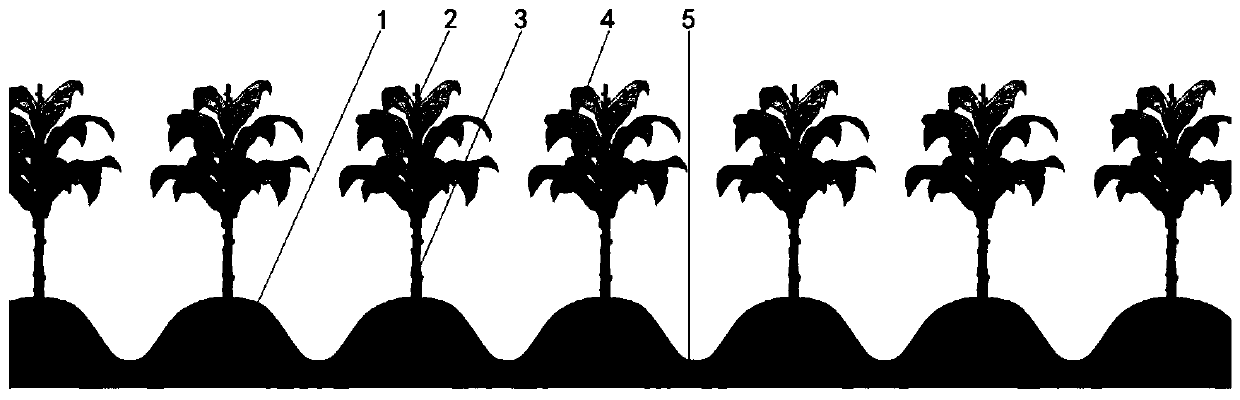

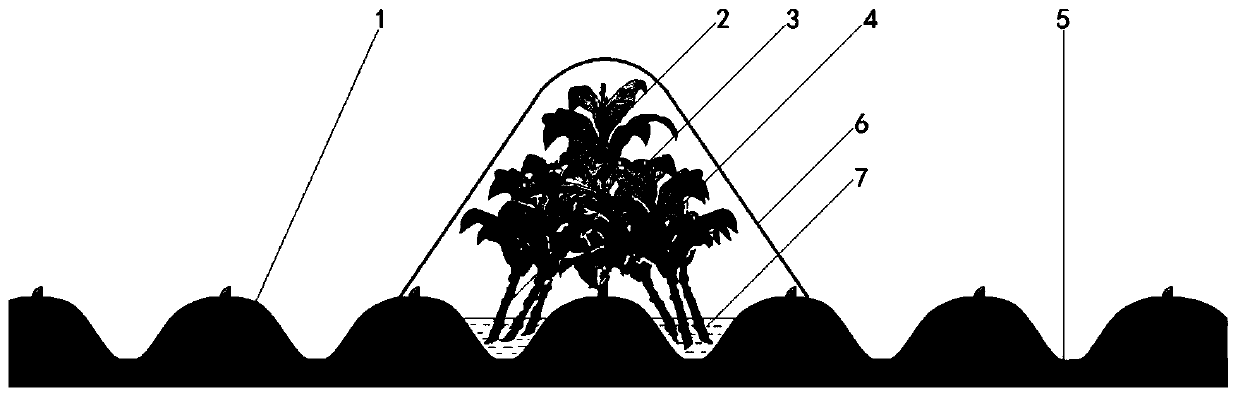

[0071] like figure 1 , figure 2 Shown:

[0072] Select a representative tobacco strain 2 in a tobacco field 1, and the stem 3 of each tobacco strain has 10 leaves with tobacco leaves 4. After the tobacco strain 2 is cut off at the base of the stem 3, it stands on In the ditch 5 of the water 7, the top of the tobacco plant 2 is shaded with a black film 6.

[0073] After shading water for 6 days to June 14, all the tobacco leaves were picked at one time. After picking, they were divided into three groups A1, A2, and A3 according to the color of the leaves from yellow to green, and they were put into three curing rooms for baking. ...

Embodiment 3

[0075]From August 30, 2019 to the end of September, the invention was repeatedly verified in Taipingzhuang Township, Jianping County, Chaoyang City, Liaoning Province and Beitazi Township, Beipiao County, respectively. The results show that the tobacco leaves with less than 12 leaves, cut and harvested at the base of the stem, and fully shaded with 2-3 layers of black hail-proof nets, have significantly improved maturity, more loose and soft leaf structure, and more oil content. The color is more intense, bouncy and stretchable. However, the tobacco leaves that use semi-shading (single-layer black hail-proof nets) for hydroculture, full-shade anhydrous, and full-shade water culture with insufficient water (refers to the fact that there is shading in the field but the rhizosphere soil water holding capacity of the tobacco plants that have not been harvested) are not sufficient. Effectively improve the maturity of tobacco leaves. Jianping County suffered a severe frost disaster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com